A kind of dispersed downcomer sieve plate column

A technology of sieve tray column and liquid drop, applied in the field of mass transfer and separation, can solve the problems of small effective mass transfer area, easy blockage, low operating elasticity of sieve tray, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

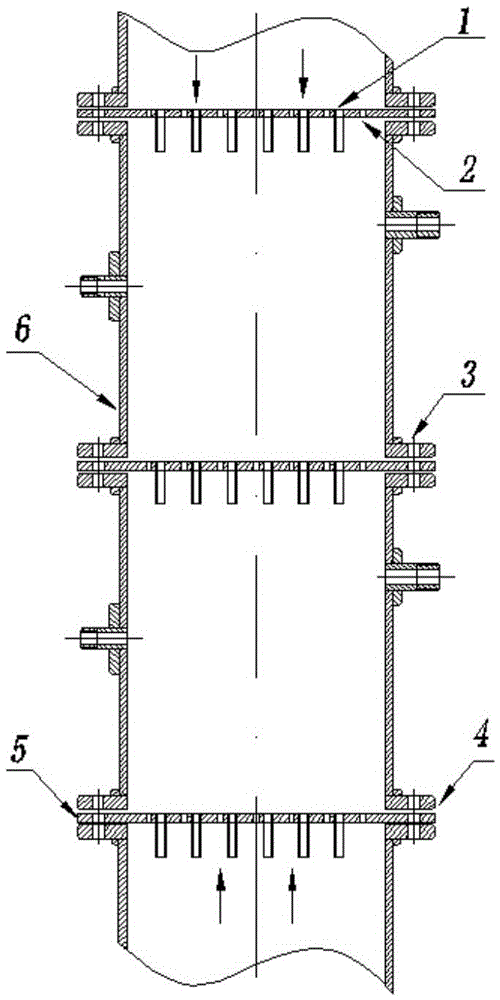

[0018] The invention provides a dispersed downcomer sieve plate tower, such as figure 1 The shown includes a cylindrical tower body 6, and several sieve plates 5 are installed along the axial direction of the tower body 6. If you want to improve the mass transfer efficiency or complete a certain chemical reaction at the same time, you can also fill between every two sieve plates 5 Packing or catalyst for mass transfer.

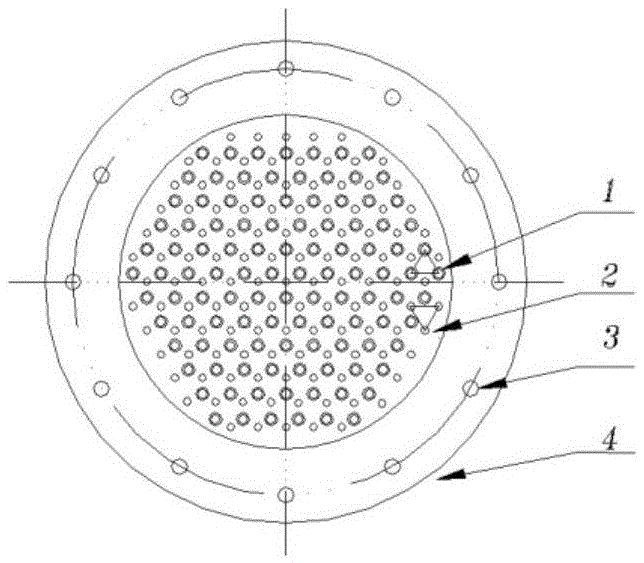

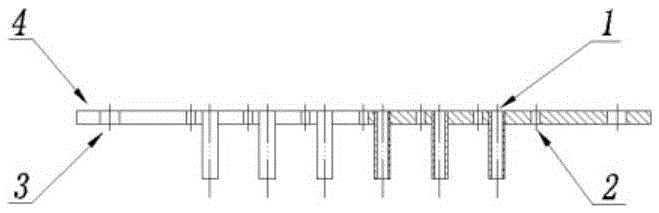

[0019] Such as figure 2 As shown, the sieve plate 5 includes a tray 4, the middle part of the tray 4 (in the dotted circle area) is uniformly provided with some air holes 2 and some downcomers 1, and the edge of the tray 4 is uniformly provided with some flange holes 3, The sieve plate 5 is sealed and installed on the tower body 6 through the flange hole 3, and every three air holes 2 are arranged in an equilateral triangl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com