A kind of water rectification packing with surface micro-nano structure and preparation method thereof

A technology of nanostructure and water polishing, applied in chemical instruments and methods, fractionation, chemical/physical/physicochemical processes, etc., can solve the problems of height and volume, reduce investment cost and energy consumption, and increase effective mass transfer area, the effect of reducing packing height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] A preparation method of a water rectification packing with surface micro-nano structure, the method is suitable for bulk packing and structured packing, and the steps include:

[0039] S1: Use a degreasing agent or an organic solvent to degreasing and degreasing the raw material of the water rectification filler;

[0040] S11: Select a degreasing agent or an organic solvent according to the content of oil stains on the surface of the water rectification filler material, wherein the degreasing agent is tridecyl ether polyoxyethylene, Triton X-100, α-phenylmethyl-ω-[ (1,1,3,3-Tetramethylbutyl)phenoxy]-poly(oxy-1,2-ethylene), methyloxirane and monooctylphenyl ether branched epoxy The mass fraction of ethane polymer, 10-ethoxy-9,9-dimethyl-1-decylamine, sodium xylene sulfonate, and polyoxyethylene octyl phenol ether is 0.1% to 20% The aqueous solution; the organic solvent is a water-soluble organic solvent or a mixture of a water-soluble organic solvent and water;

[0041...

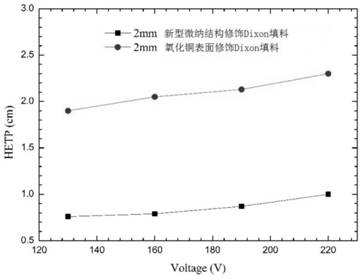

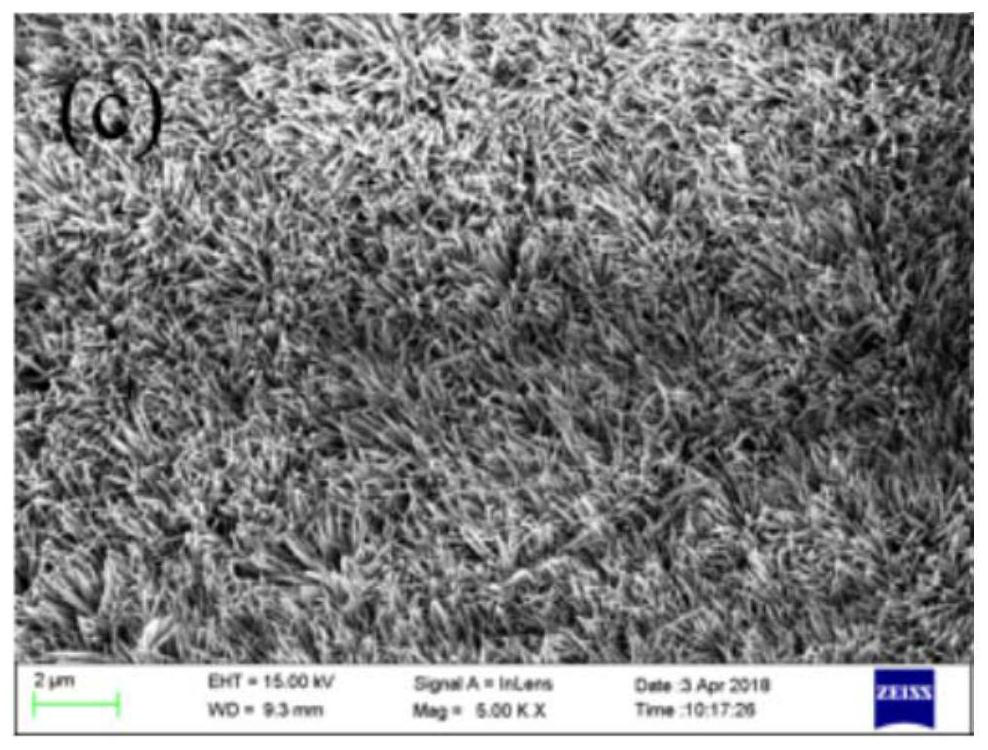

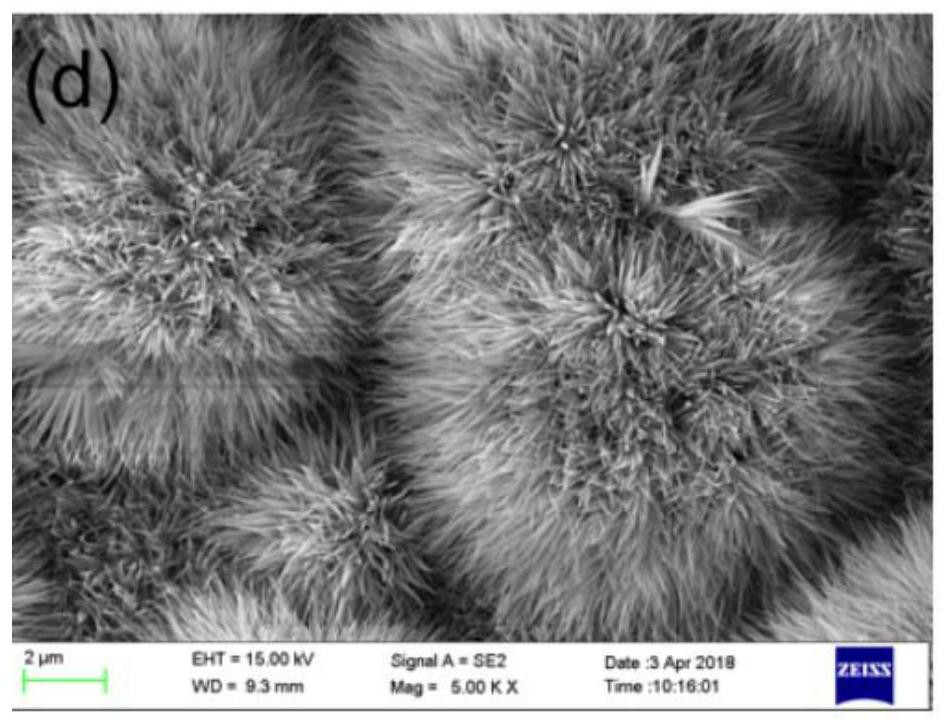

Embodiment 1

[0052] Immerse the 2×2mm Dixon water rectification packing in 200ml acetone solution, use ultrasonic cleaning for three times to remove the grease attached to the surface, and then wash with deionized water three times to remove the residual acetone on the surface of the packing; then wash the Dixon water after cleaning. The rectification packing is placed in the plasma cleaning device, and the air in the plasma is pumped to 100pa under air conditions to realize glow discharge and hydroxylate the surface of the Dixon water rectification packing; then the Co(NO 3 ) 2.6 H 2 O was dissolved in 250ml of solution, glycine and urea were added, and Co(NO 3 ) 2.6 H 2 The mass ratios of O, glycine and urea were 1:0:1, 1:0.5:1.1 and 1:1:1.2, respectively, and the mixed solutions obtained under different ratios were recorded as M1, M2 and M3, respectively; the surface hydroxylated The Dixon water rectifying fillers were placed in the mixed solutions of M1 to M3, and after stirring su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com