Combined washing fuel tank and use method thereof

A combined, fuel tank technology, applied in cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., can solve the problems of inapplicability in high temperature seasons, no coolers, etc., to achieve convenient storage and transportation, easy installation and operation, Reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions provided by the present invention will be described in detail below with reference to specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and not to limit the scope of the present invention.

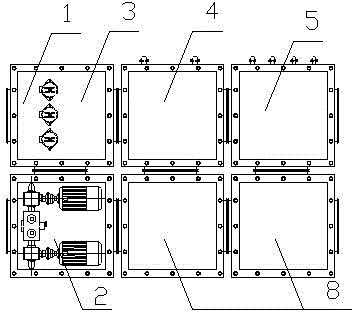

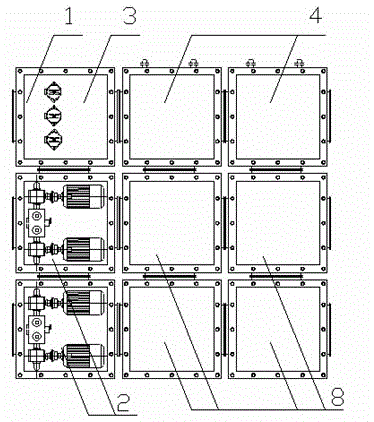

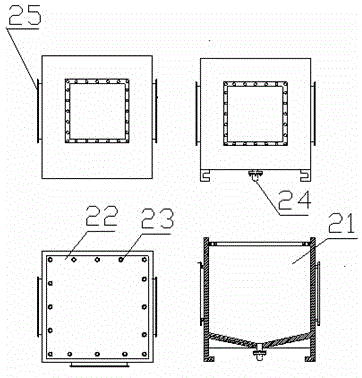

[0036] like Figure 1 to Figure 11 The above-mentioned combined flushing oil tank is composed of different functional units, pump unit 2, oil return unit 3, cooling unit 4, heating unit 5, conduction plate 6 and blind Plate 7, filter unit 8, wherein the filter unit 8 is further divided into four-pass filter unit and three-pass filter unit, stud bolts and nuts and other components.

[0037] The basic box 1 is used as the basis for other functional units. The external dimensions of each basic box 1 are exactly the same as the size and height of the rectangular manhole, which can be used universally and interchangeably. Different devices are installed on the basic box to form d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com