Device and method for abrasive material multilayer orderly arraying

A technology of abrasives and abrasive grains, which is applied in the field of devices with multi-layered and orderly arrangement of abrasives, which can solve problems such as unsuitable for large-scale production, disordered blanking position, and irregular arrangement, and achieve convenient multi-layered and orderly arrangement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

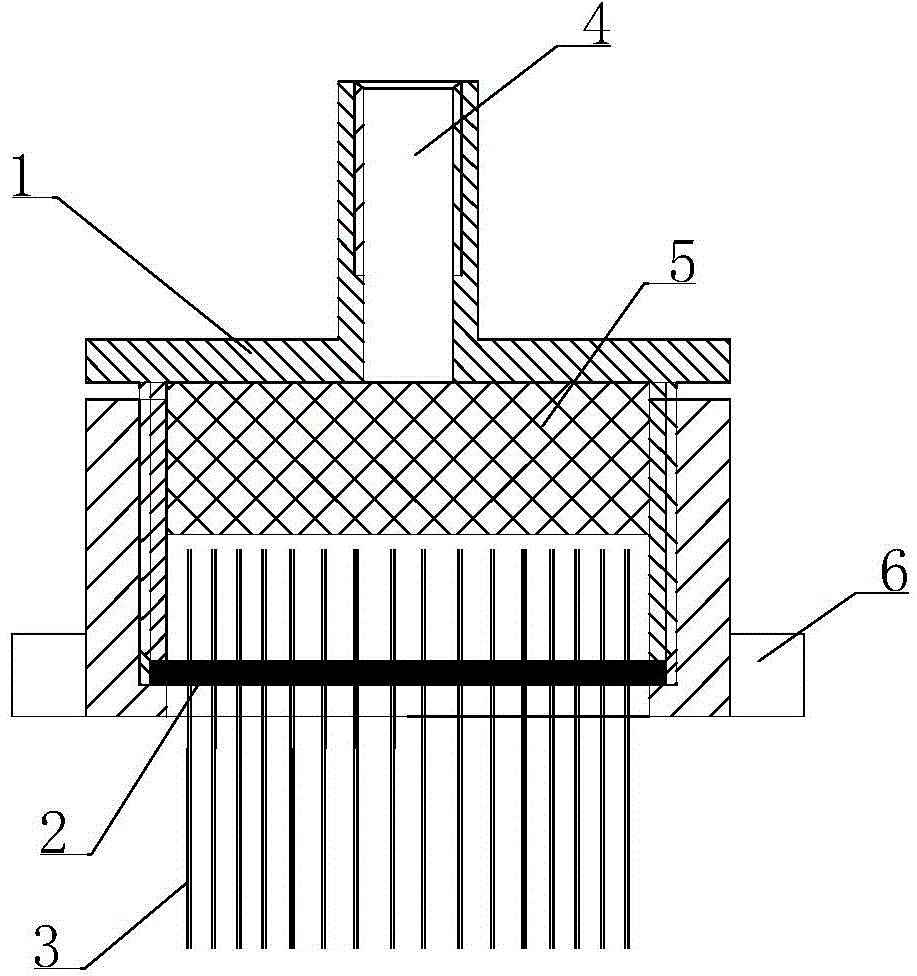

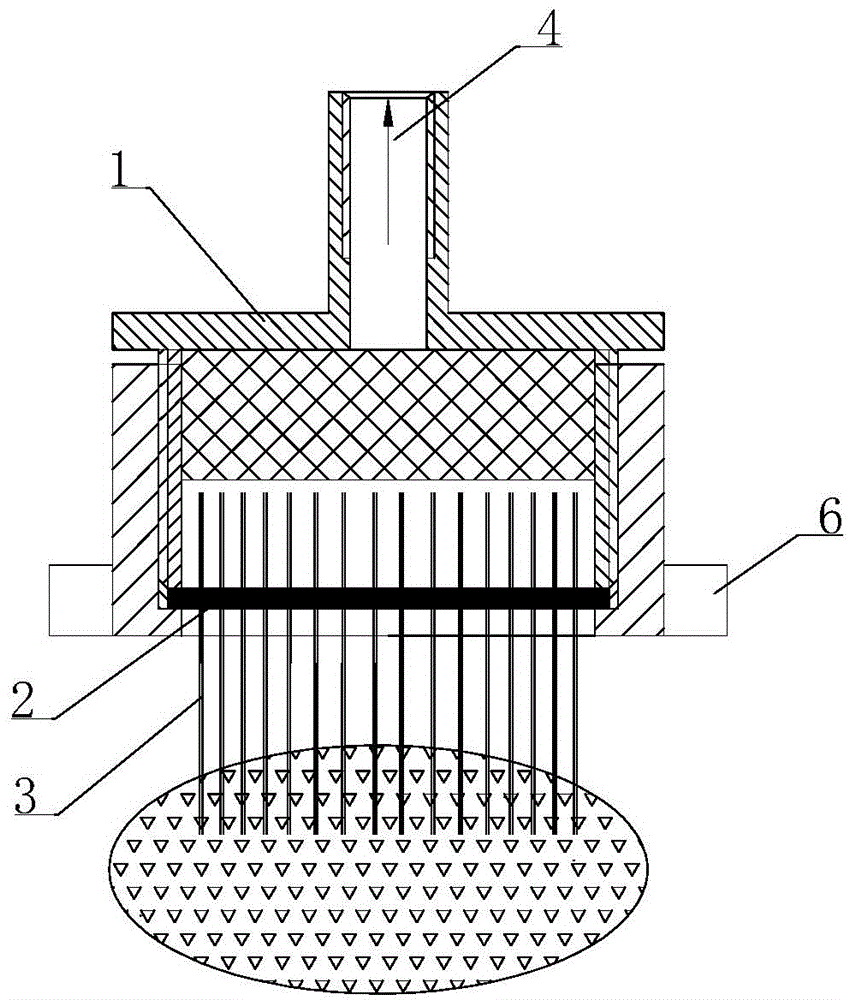

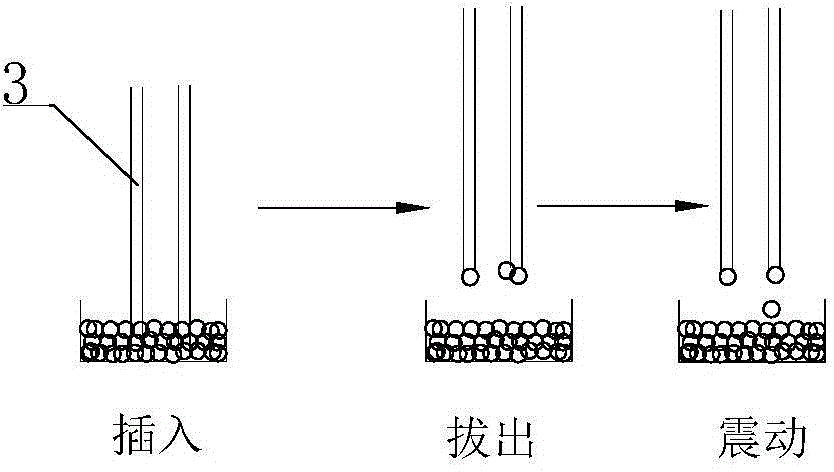

[0032] Such as figure 1 The shown device with multiple layers of abrasives arranged in an orderly manner includes a cavity that can form positive or negative pressure. The cavity is surrounded by the cylinder liner 1 above and the partition 2 at the bottom. The thickness of the partition 2 is 2-5mm , which is covered with through holes arranged in an orderly manner, and the shape of the orderly arrangement can be determined according to the characteristics of the abrasive tool. A suction pipe 3 is fixedly connected to each through hole. The suction pipe 3 is a straight pipe with openings at both ends. The opening at the top is located in the cavity. The bottom end of the abrasive grain is open. The length of the suction pipe 3 is 12-40mm, and the inner diameter is 0.16-0.80mm. At the same time, the inner diameter of the suction pipe 3 should be about 2 / 3 of the diameter of the abrasive grains, so as to prevent the abrasive grains from being sucked into the suction pipe 3. Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com