Simple sorting robot

A robot and simple technology, applied in the directions of manipulators, chucks, manufacturing tools, etc., can solve the problems of high cost, waste of resources, complex structure of sorting robots, etc., and achieve the effect of low cost, small number of components, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

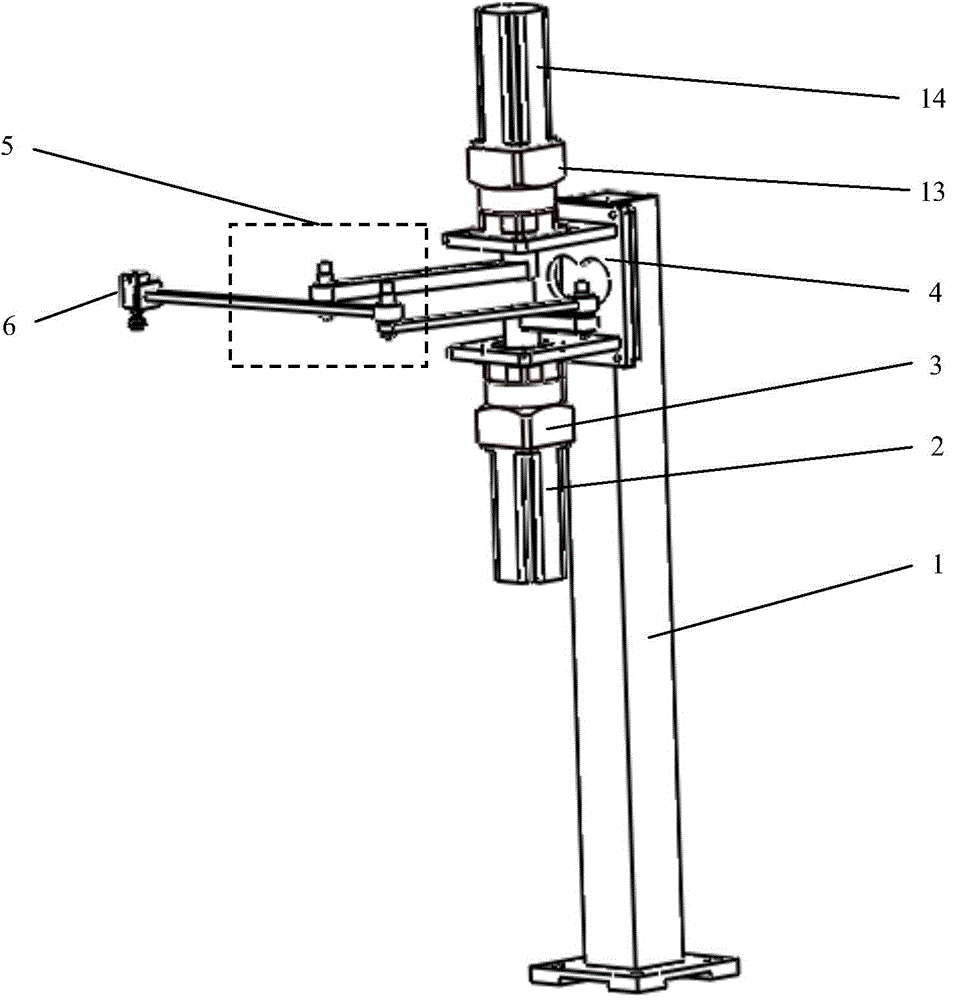

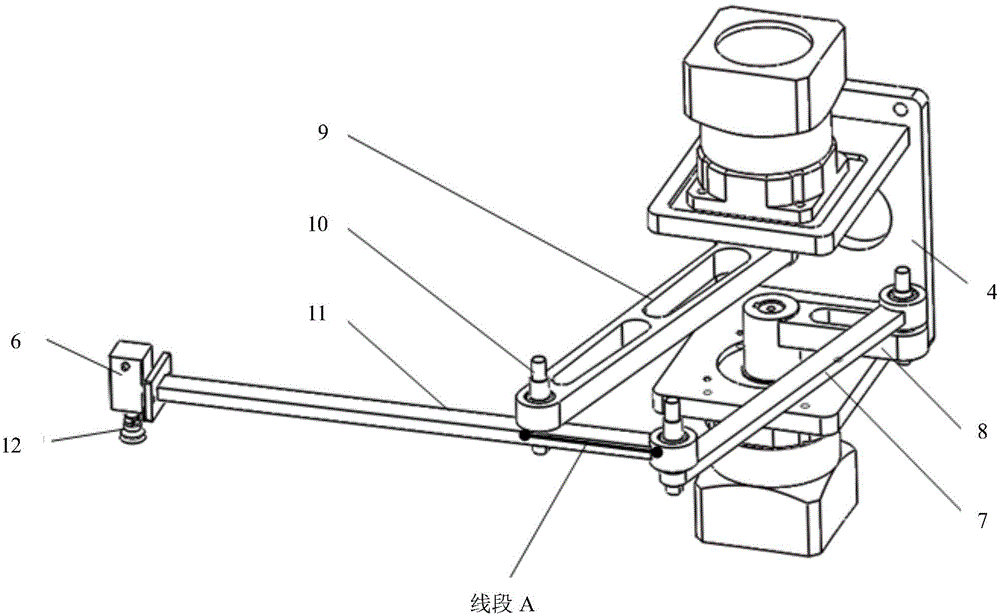

[0013] like figure 1 , figure 2 As shown, a simple sorting robot includes a base part, a driving device (the first motor 2 and a first reducer 3), a four-bar linkage mechanism 5, a cylinder 6 and a suction cup 12; the driving device is installed on the base 4 Above, the four-bar linkage mechanism 5 is connected with the driving device through a flat key, the cylinder 6 is installed at the end of the four-bar linkage mechanism 5, and the suction cup 12 is installed on the piston rod of the cylinder.

[0014] like figure 1 As shown, the column 1 is a hollow square steel material, which supports the robot at a certain height so as to facilitate the sorting operation on the corresponding production line; the first motor 2 is fixed to the first reducer by bolts 3, the first reducer 3 is fixed on the base 4 by bolts; the first reducer 3 adopts a harmonic reducer to improve transmission accuracy and reduce vibration.

[0015] like figure 2 As shown, the four-bar linkage mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com