Three-scraper wiper blade hydraulic windscreen wiper with flexible wall supporting

A flexible wall, hydraulic technology, used in vehicle cleaning, vehicle maintenance, transportation and packaging, etc., can solve the problems of high noise, hidden dangers of driving safety, low scraping degree, etc., to reduce the noise inside the vehicle and transmit large torque. , Improve the effect of scraping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

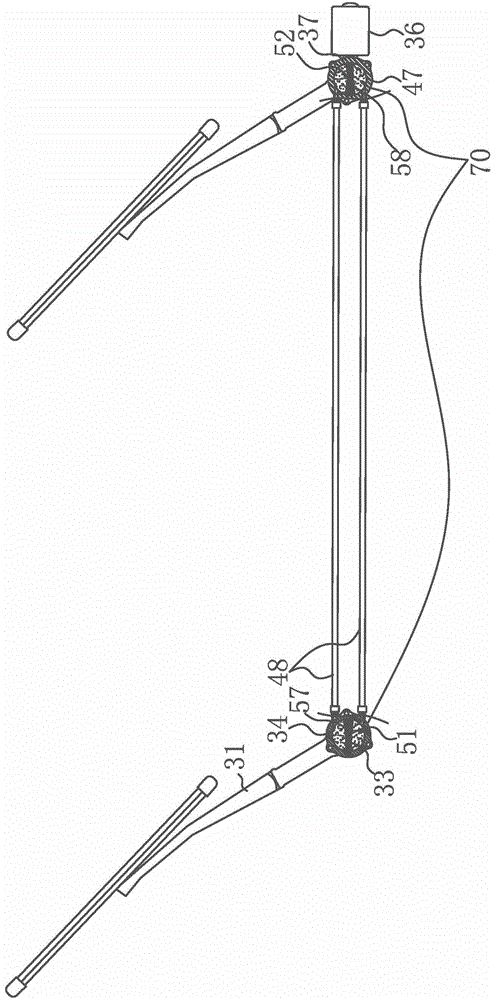

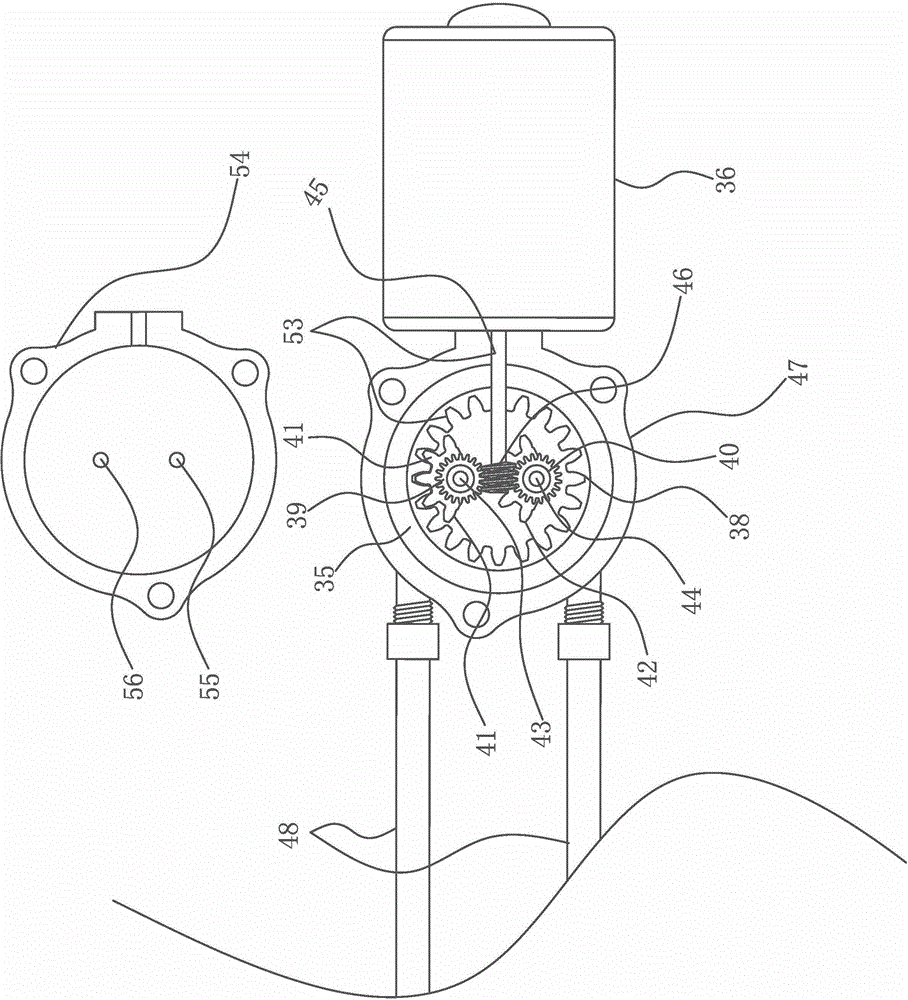

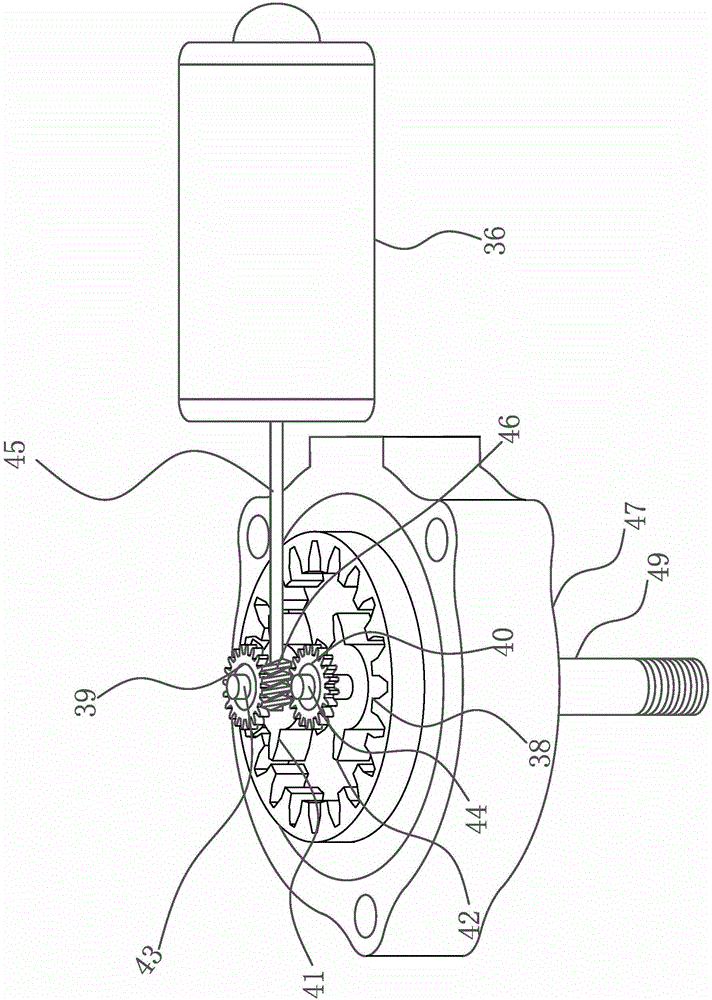

[0018] Figure 1-Figure 7 In an embodiment, a three-blade flexible wall supporting wiper blade hydraulic wiper includes a wiper motor (36), a wiper drive mechanism (70) and a wiper (31), and is characterized in that: the wiper drive shaft (50) is divided into two parts. The passive wiper drive shaft (32) and the active wiper drive shaft (49) are respectively coaxial with the passive oil cylinder shaft (51) of the passive blade swing oil cylinder (34) and the active oil cylinder shaft (52) of the active blade swing oil cylinder (47) connected; the passive oil cylinder shaft (51) and the active oil cylinder shaft (52) are respectively provided with a passive oil cylinder partition plate (33) and an active oil cylinder partition plate (37), a passive vane swinging oil cylinder (34) and an active vane swinging oil cylinder (47). ) through the hydraulic oil pipe (48) to communicate and transmit torque; a positive and negative gear intermittent transmission mechanism (53) is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com