Candy moving and paper folding mechanism of candy wrapping machine

A packaging machine and candy technology, applied in the fields of sugar transfer origami and candy packaging machines, can solve the problems of high maintenance cost, complex internal structure of the transfer mechanism, easy failure, etc., and achieve the effects of simple structure, high reliability and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with figures and embodiments.

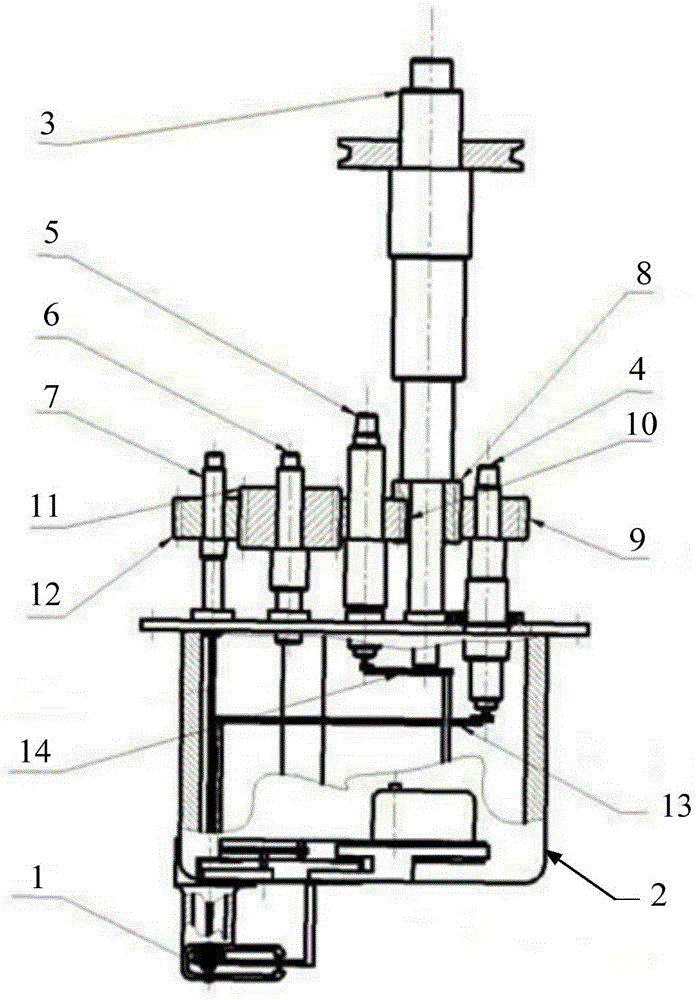

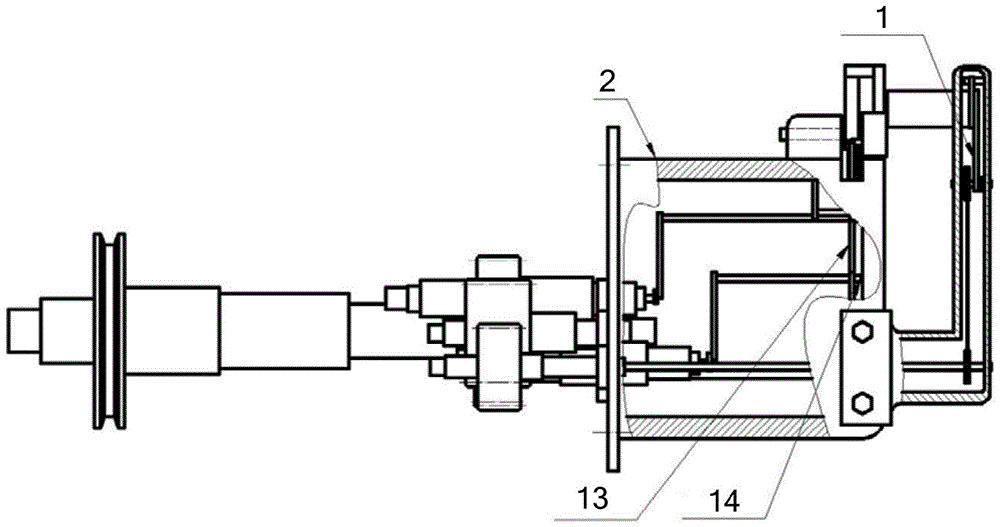

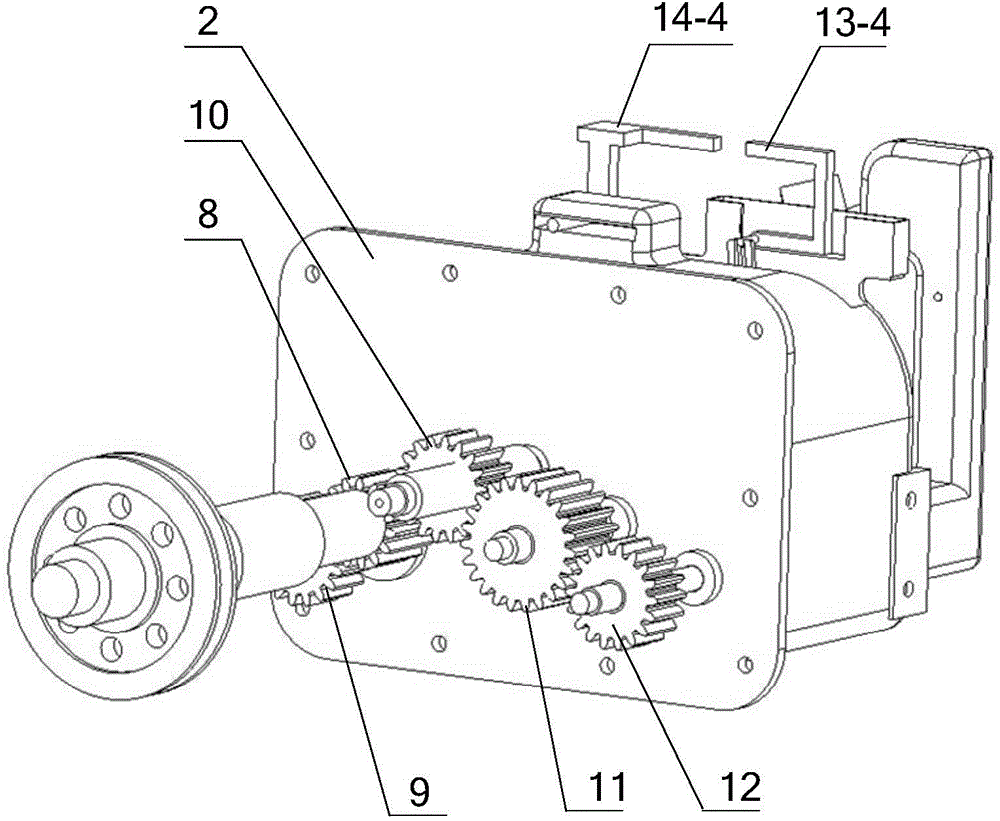

[0013] Such as figure 1 , 2 As shown in and 3, a sugar-moving origami mechanism of a candy packaging machine includes a sugar-moving frame 2, a sugar-moving main shaft 3, a sugar-moving first transmission shaft 4, a sugar-moving second transmission shaft 5, and a sugar-moving third transmission shaft 6. The fourth transmission shaft of Yitang 7, the driving gear of Yitang 8, the first transmission gear of Yitang 9, the second transmission gear of Yitang 10, the third transmission gear of Yitang 11, the fourth transmission gear of Yitang 12, the sugar Rod group 13, sugar pushing rod group 14 and origami rod group 1; sugar-removing main shaft 3, sugar-removing first transmission shaft 4, sugar-removing second transmission shaft 5, sugar-removing third transmission shaft 6 and sugar-removing fourth transmission shaft 7 are all supported on the sugar-removing frame 2 throu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap