Patents

Literature

42results about How to "High deformation accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

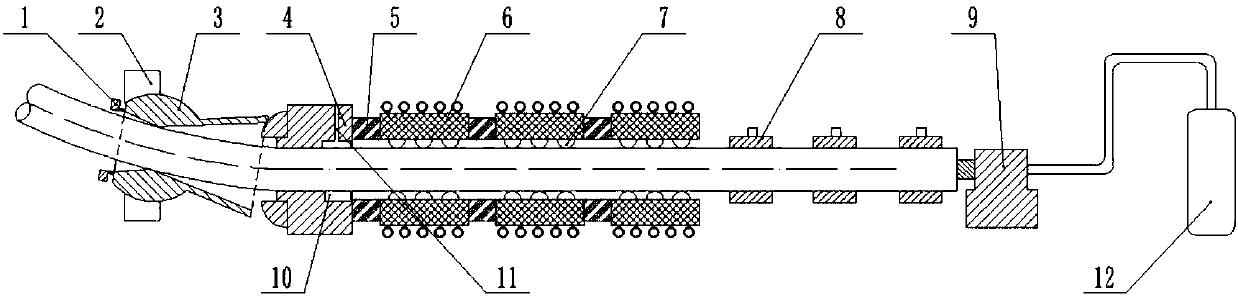

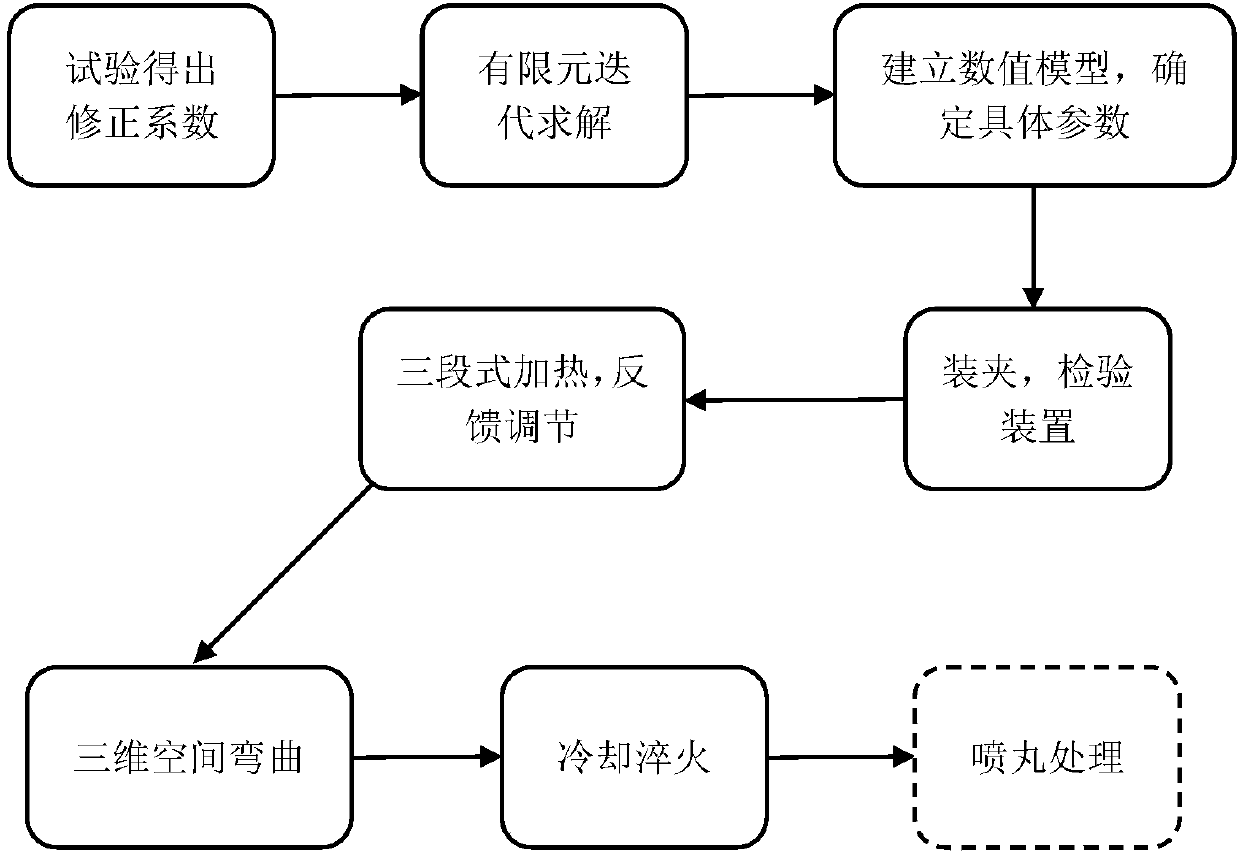

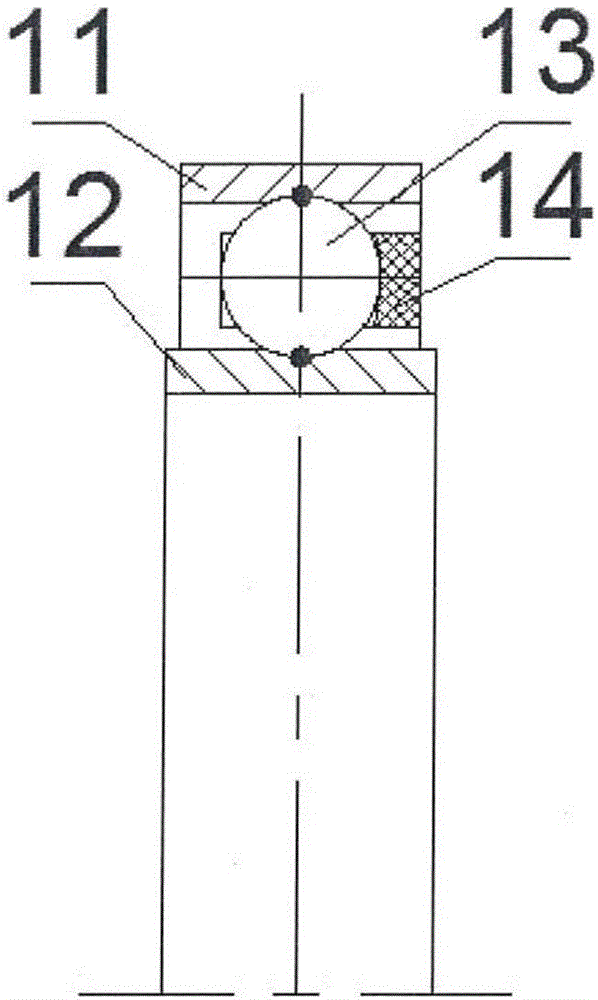

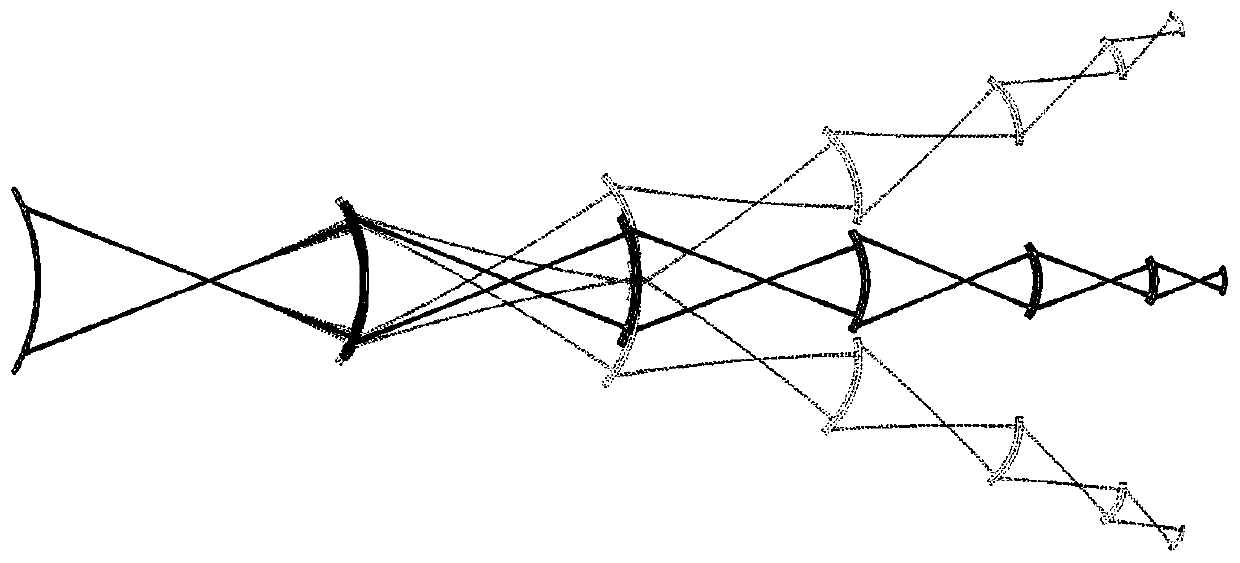

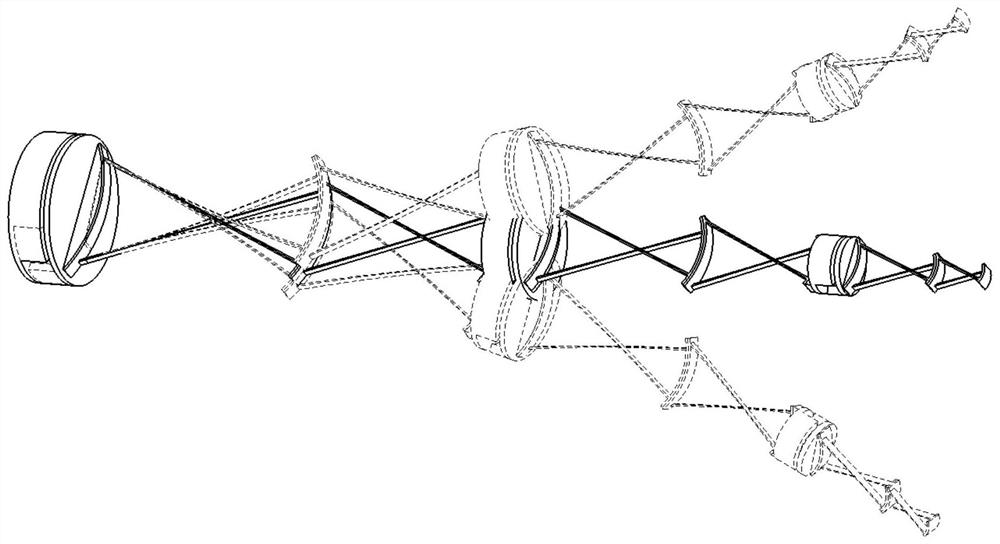

Martensite steel 3D free-bending forming device and method

ActiveCN107755490AIncrease productivityRealization of free bending pipeShaping toolsMetal-working feeding devicesNuclear powerMartensite

The invention discloses a martensite steel 3D free-bending forming device and method and belongs to the technical field of advanced manufacturing and plastic forming. Firstly, based on relative parameters of the forming performance of a pipe material, a corresponding correction factor of the material is obtained through repeated iterative calculation, and an initial model is corrected; after the using situations of parts are tested and calibrated, a three-stage type induction heating device and sensors are matched to achieve precise temperature-control heating; the three-dimensional space of abending mould rotates to extrude the front end of the pipe material to enable the front end of the pipe material to be in a bent shape with the complicated space; and the quenching process is conducted through an annular water-cooling spraying head and accordingly is rapid and uniform. The martensite steel 3D free-bending forming technical problem is solved, and high-temperature free-bending forming under the three-dimensional space is achieved; by means of a rapid quenching system, the strength of 1400 MPa or above is obtained, formation coordinated control of an ultrahigh-strength steel 3Dfree-bending member is achieved; and thus the martensite steel 3D free-bending forming device and method have important engineering application value in the fields of aerospace, rail transportation, automobiles and nuclear power.

Owner:NANJING INST OF TECH +1

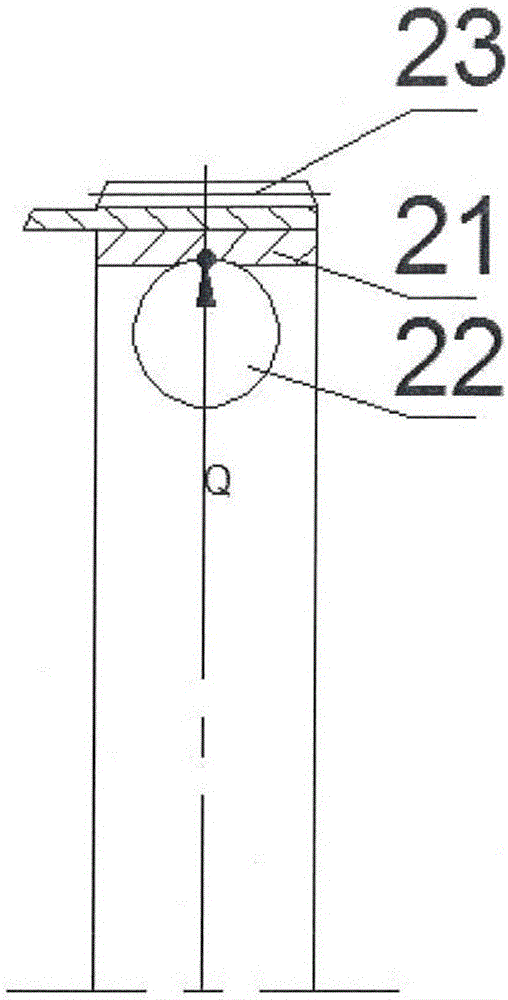

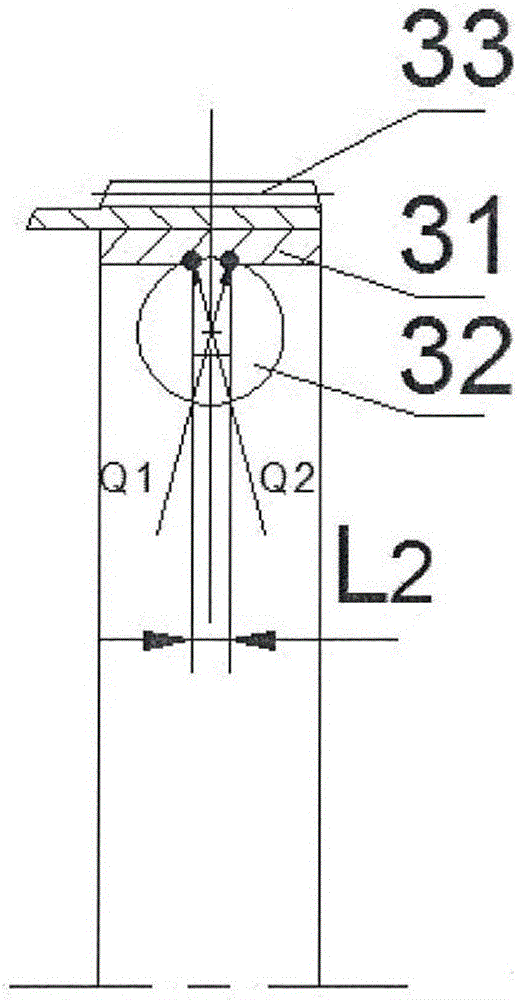

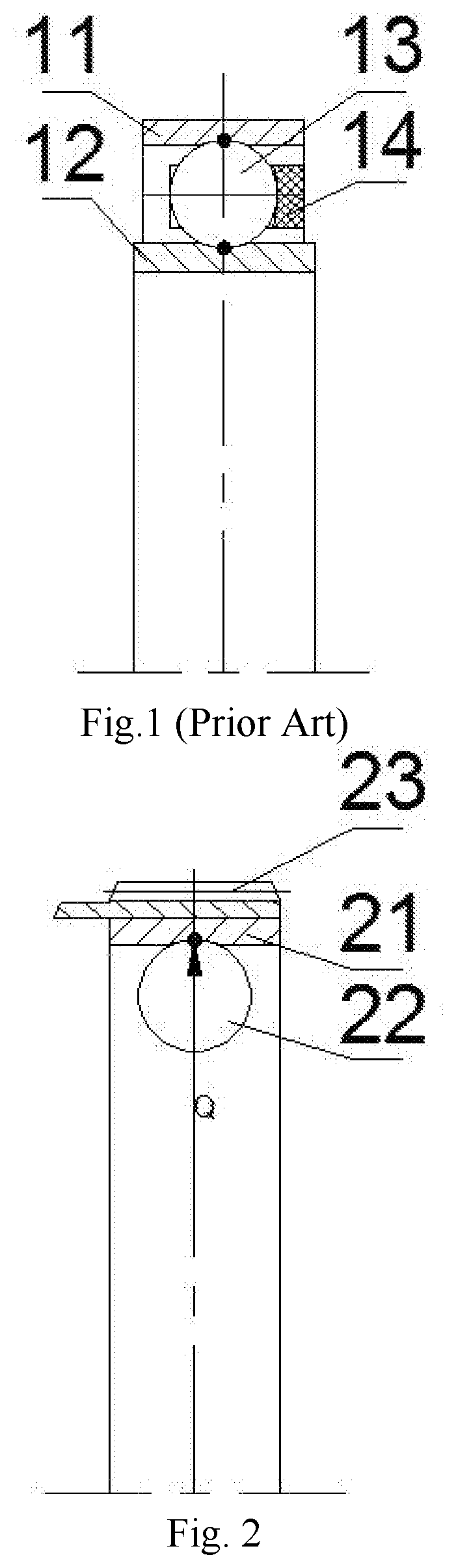

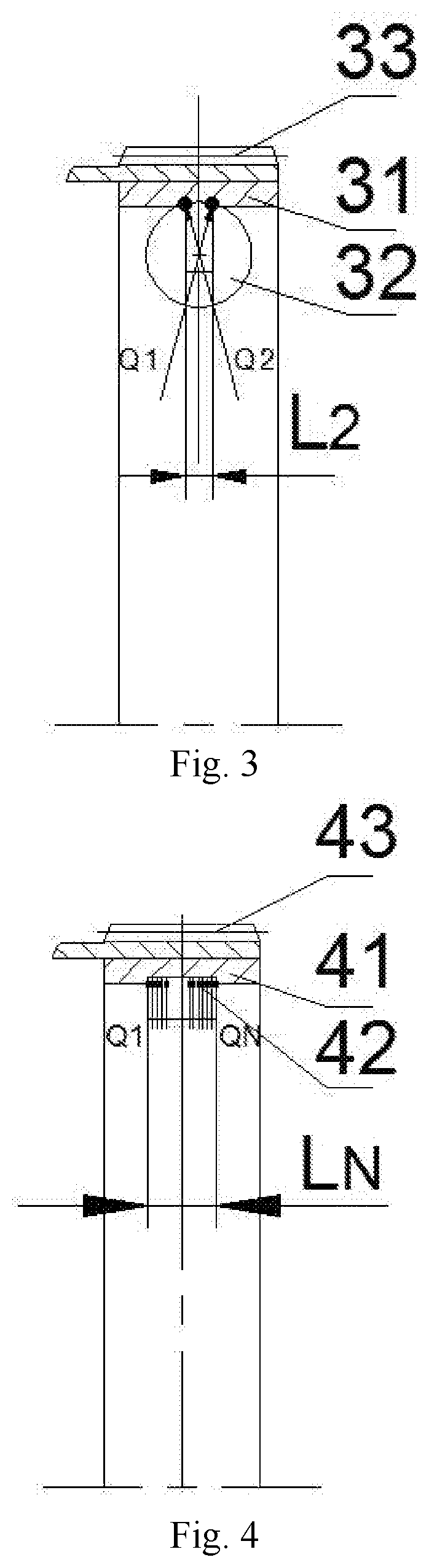

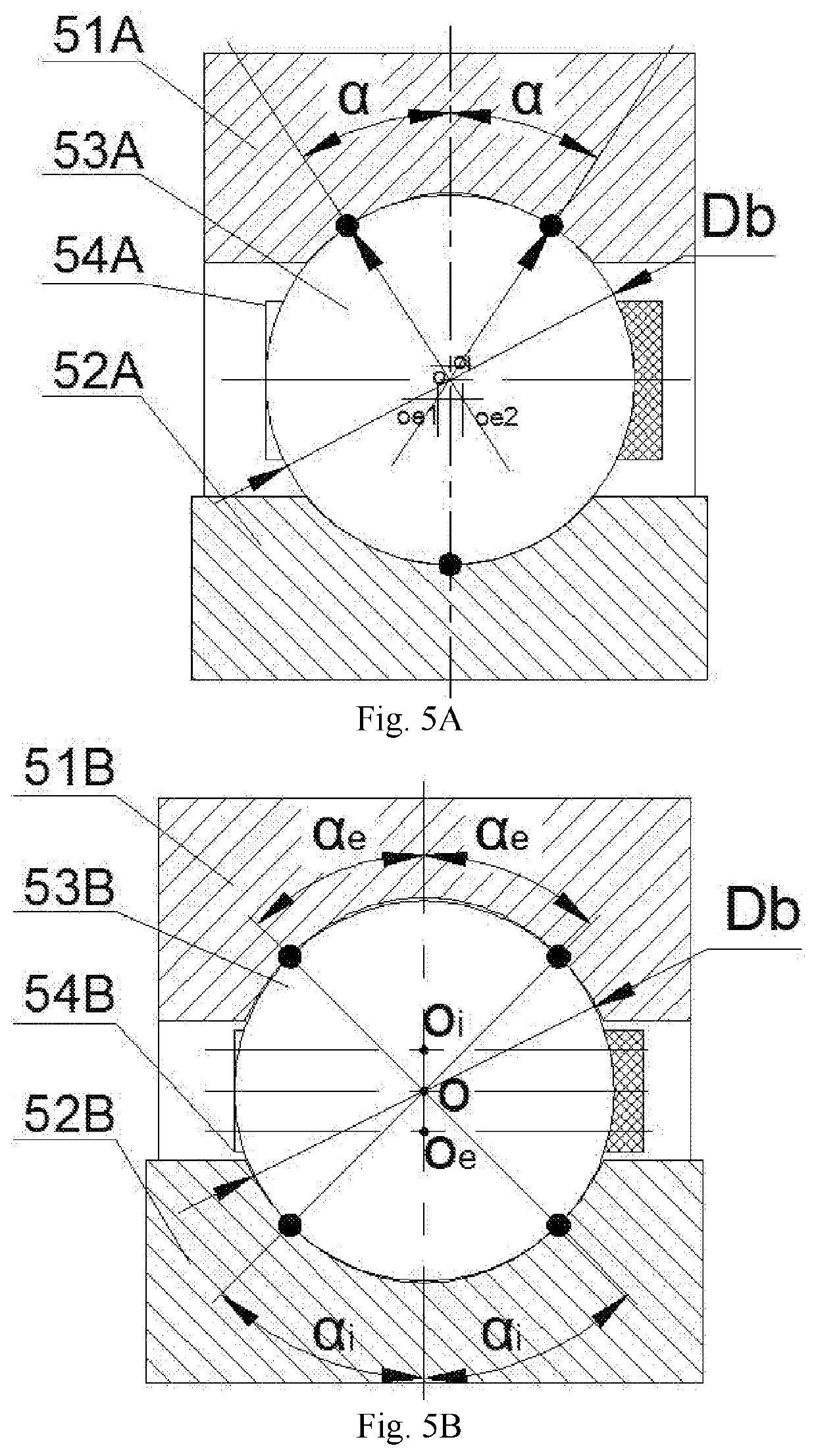

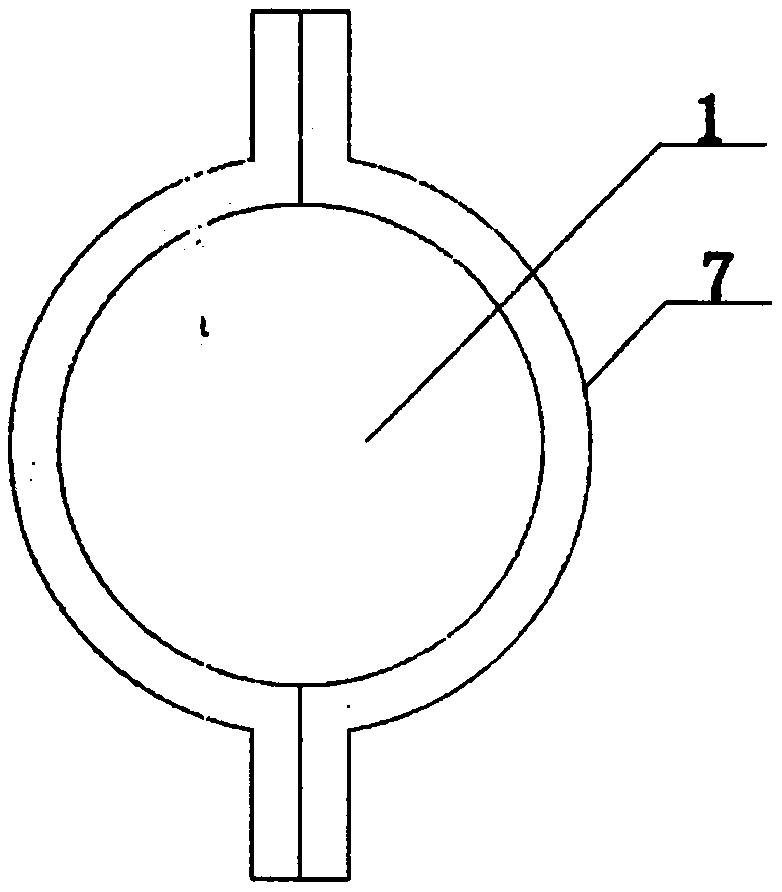

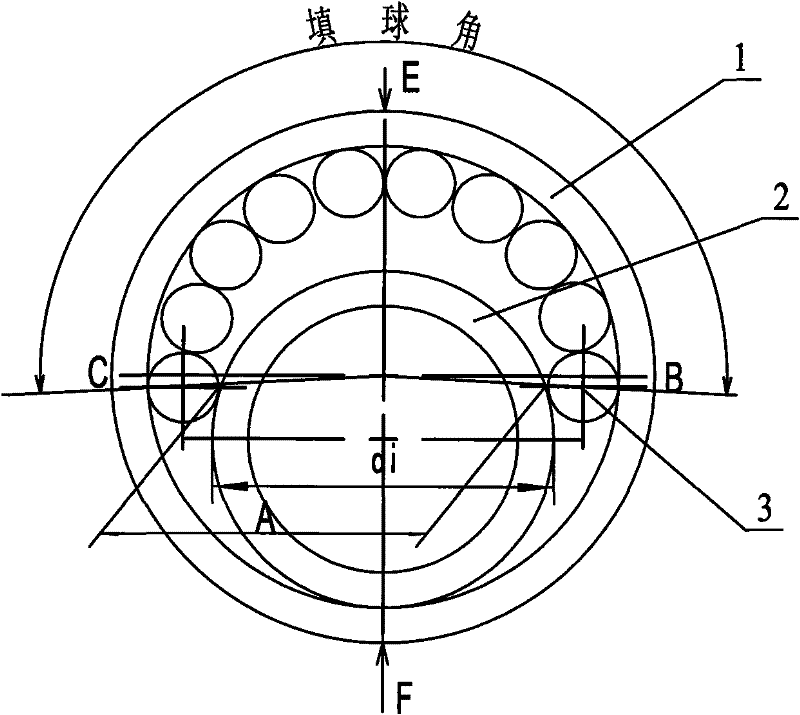

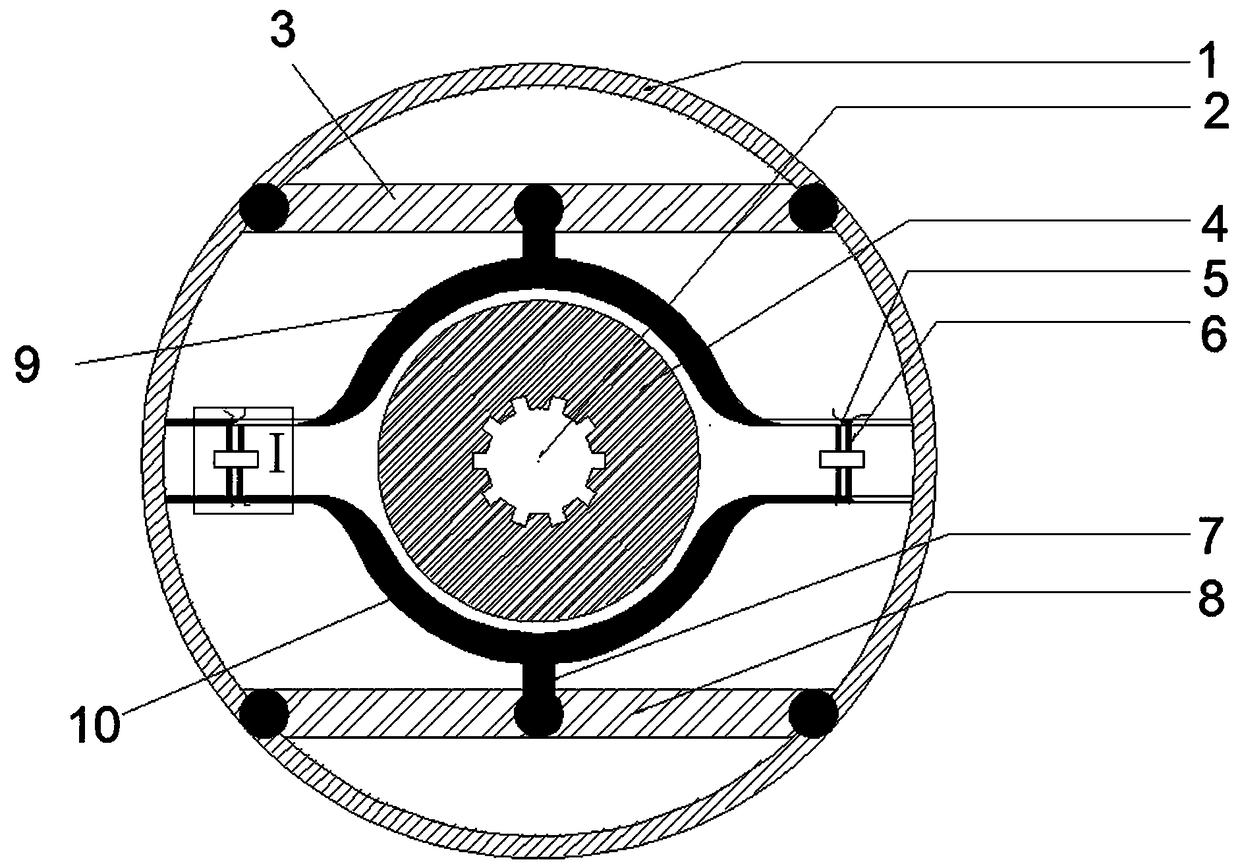

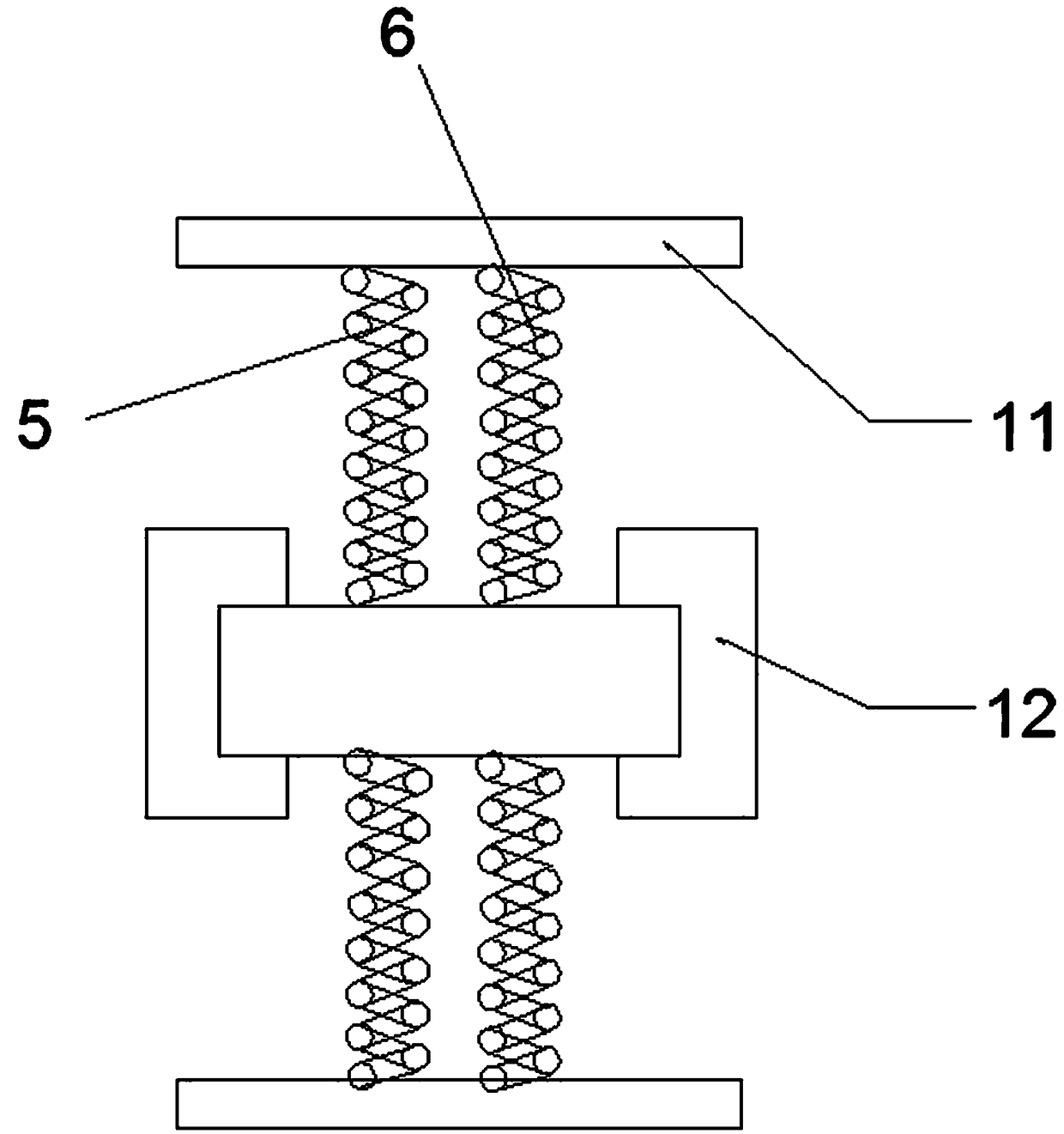

Multi-point-contact flexible bearing for harmonic reducer

ActiveCN106194999AImprove running performanceAvoid stress concentrationRolling contact bearingsGearing detailsInterference fitBall bearing

A multi-point-contact flexible bearing for a harmonic reducer comprises a three-point-contact flexible ball bearing, a four-point-contact flexible ball bearing and a line-contact flexible roller bearing; a single rolling body and an outer ring raceway, namely, an outer ring-flexible gear interference-fit piece have two or more contact points; compared with the prior art that only one contact point exists, the multi-point-contact flexible bearing has the quality and technological advantages that the given deformation precision of the outer ring-flexible gear interference-fit piece and the meshing precision of flexible gear teeth with rigid gear teeth are improved, unnecessary additional deformation is reduced and even avoided, the contact stress of the rolling body with the raceway is reduced, sliding of the rolling body is controlled, assembling conditions and lubricating conditions of the bearing during operation are improved, and the like; and finally, the running precision and the service life of the flexible bearing, a flexible gear and even the whole harmonic reducer are improved and prolonged, and the bearing has very important actual engineering significance.

Owner:SHANGHAI F&S BEARING TECH

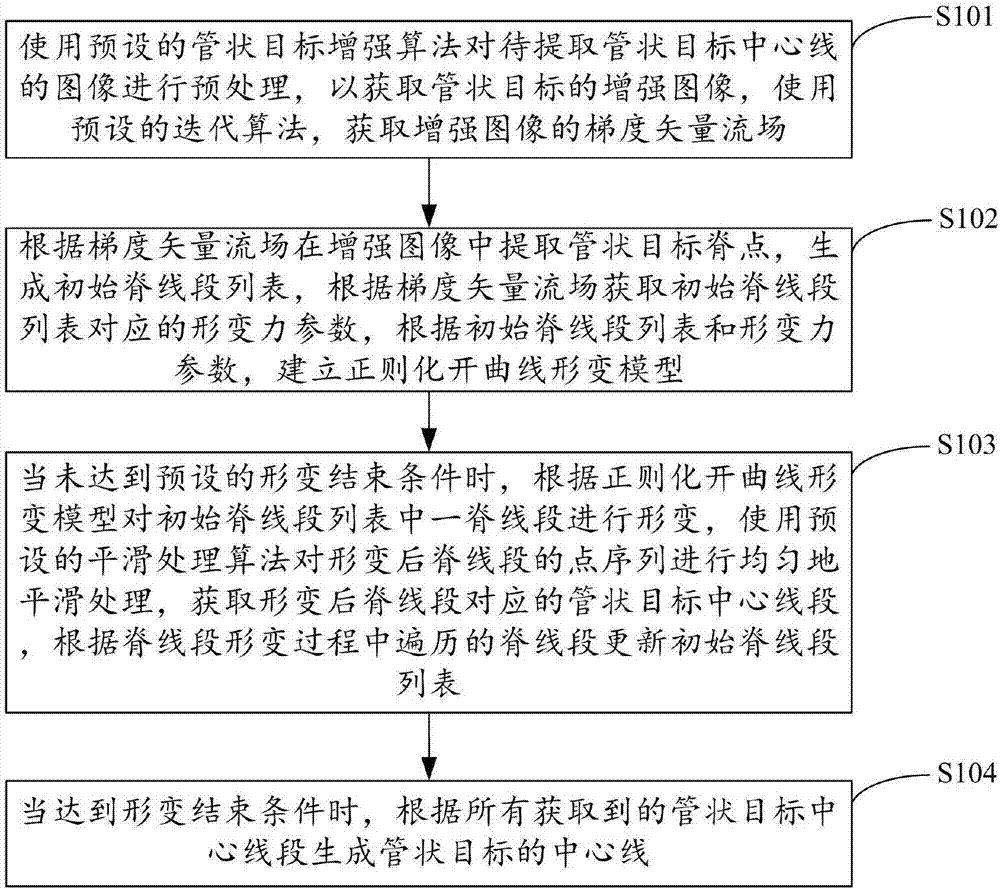

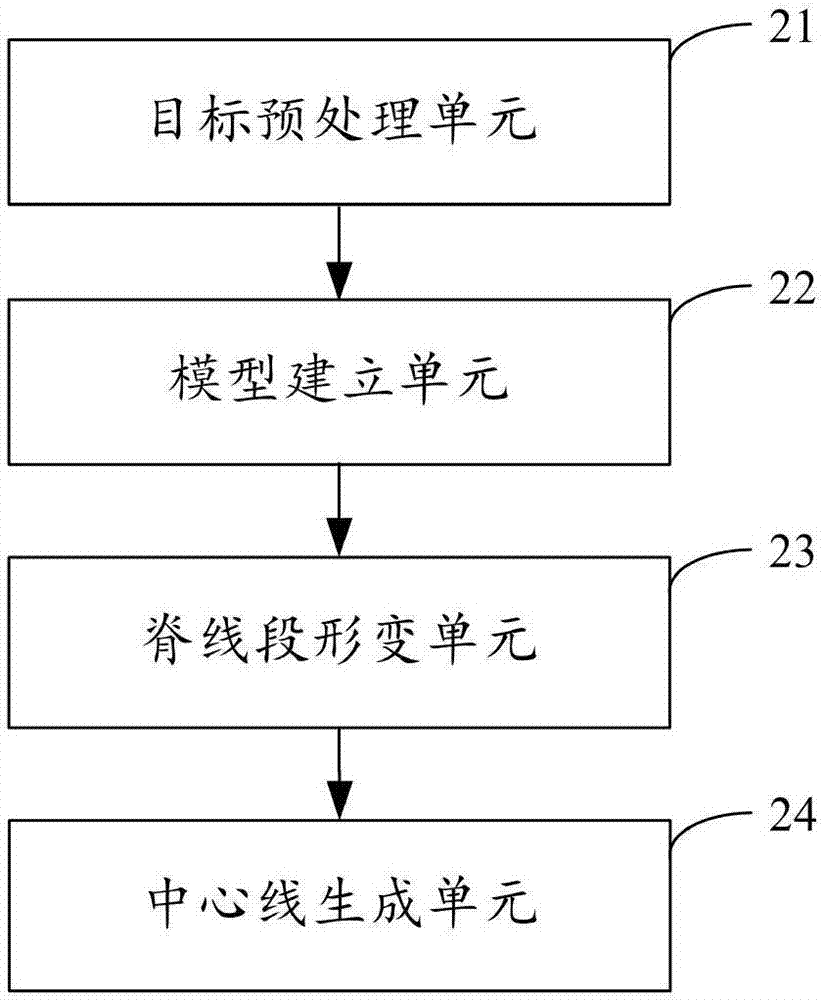

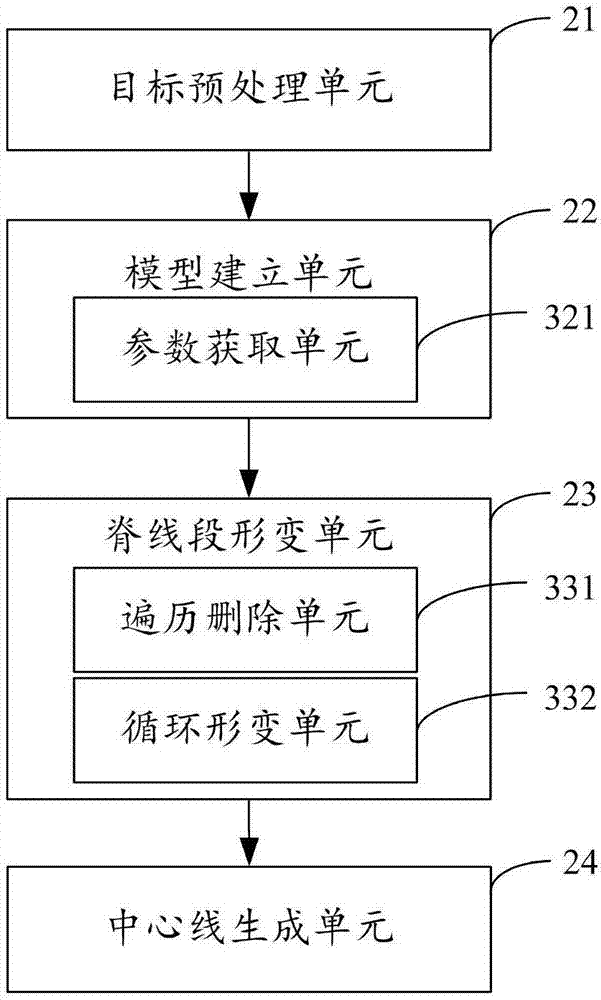

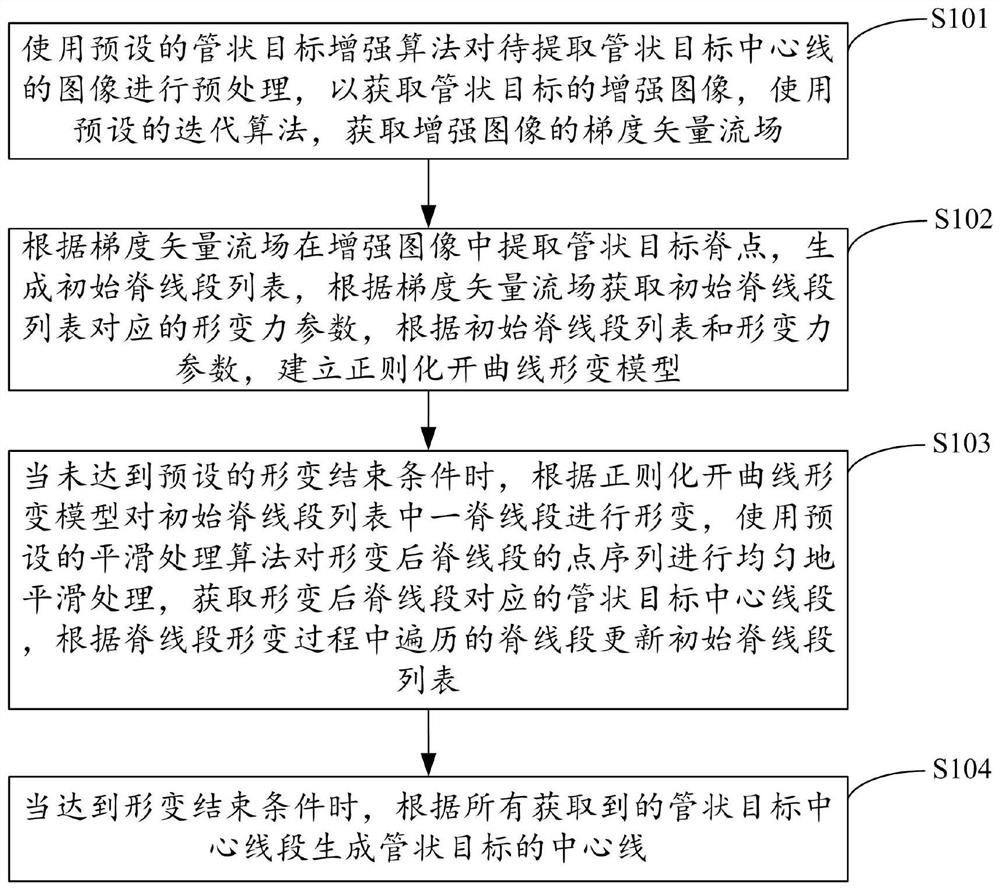

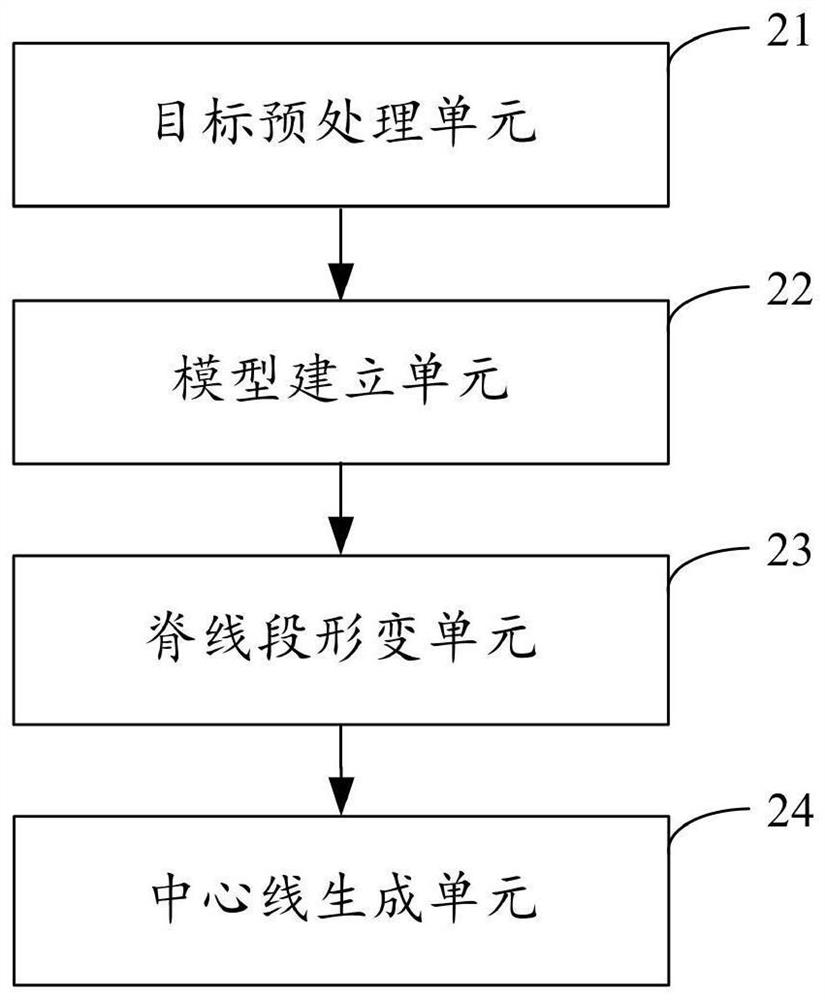

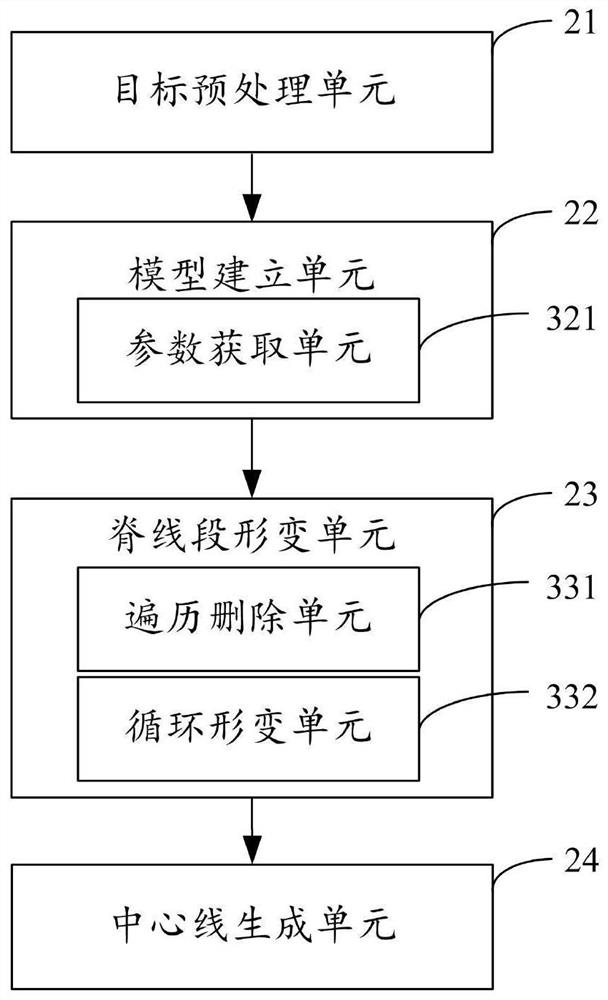

Method and device for extracting center line of tubular target

ActiveCN107330935AHigh precisionIncrease speedImage enhancementImage analysisAlgorithmComputers technology

The invention is applicable to the field of computer technologies, and provides a method and device for extracting a center line of a tubular target. The method comprises the steps of preprocessing an image of a tubular target center line to be extracted to obtain a corresponding enhanced image, acquiring a gradient vector flow field of the enhanced image, acquiring deformation force parameter corresponding to an initial ridge line segment list according to the gradient vector flow field, extracting tubular target ridge points from the enhanced image, generating the initial ridge line segment list, building a regularized open curve deformation model, performing deformation and processing on a ridge line segment in the initial ridge line segment list according to the model before a deformation ending condition is met to obtain a corresponding tubular target center line segment, updating the initial ridge line segment list according to ridge line segments traversed in the deformation process, and generating a center line of the tubular target according to the tubular target center line segments when the deformation ending condition is met, thereby optimizing the deformation process of the ridge line segments, reducing the deformation time of the ridge line segments and improving the extraction accuracy and the extraction rate of the center line.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

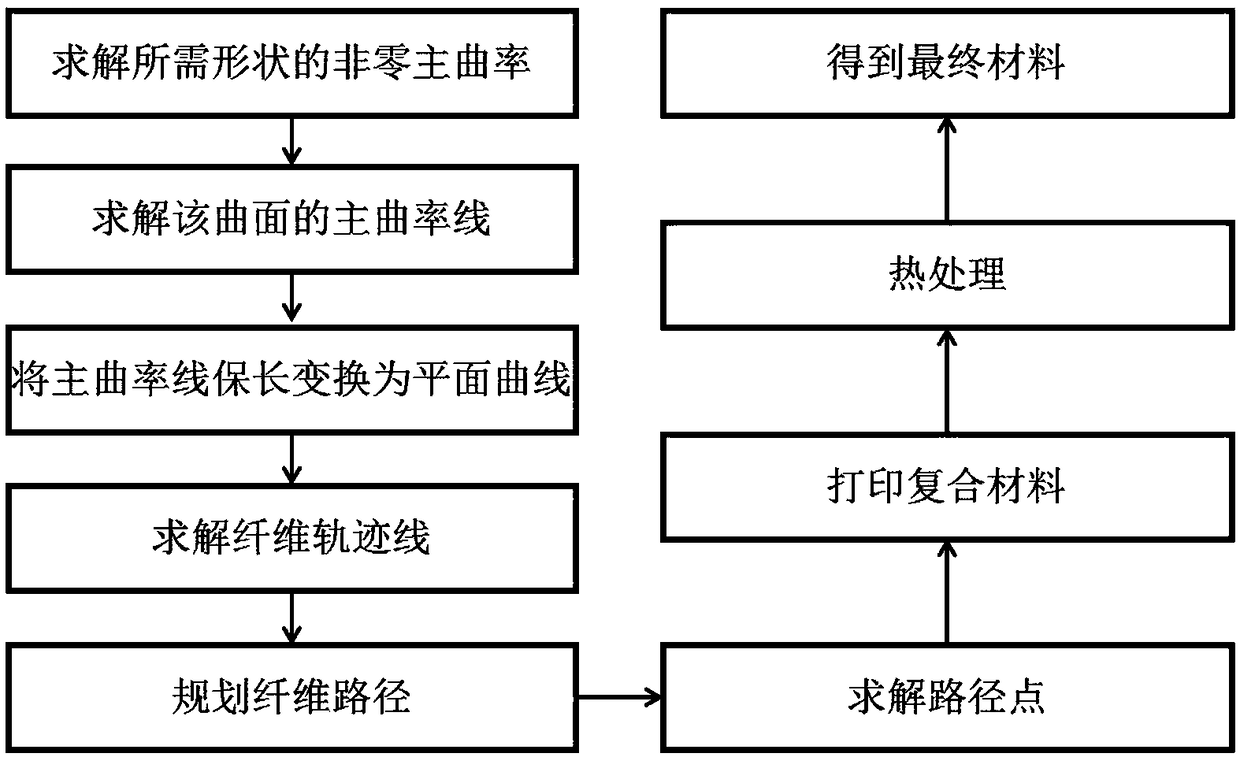

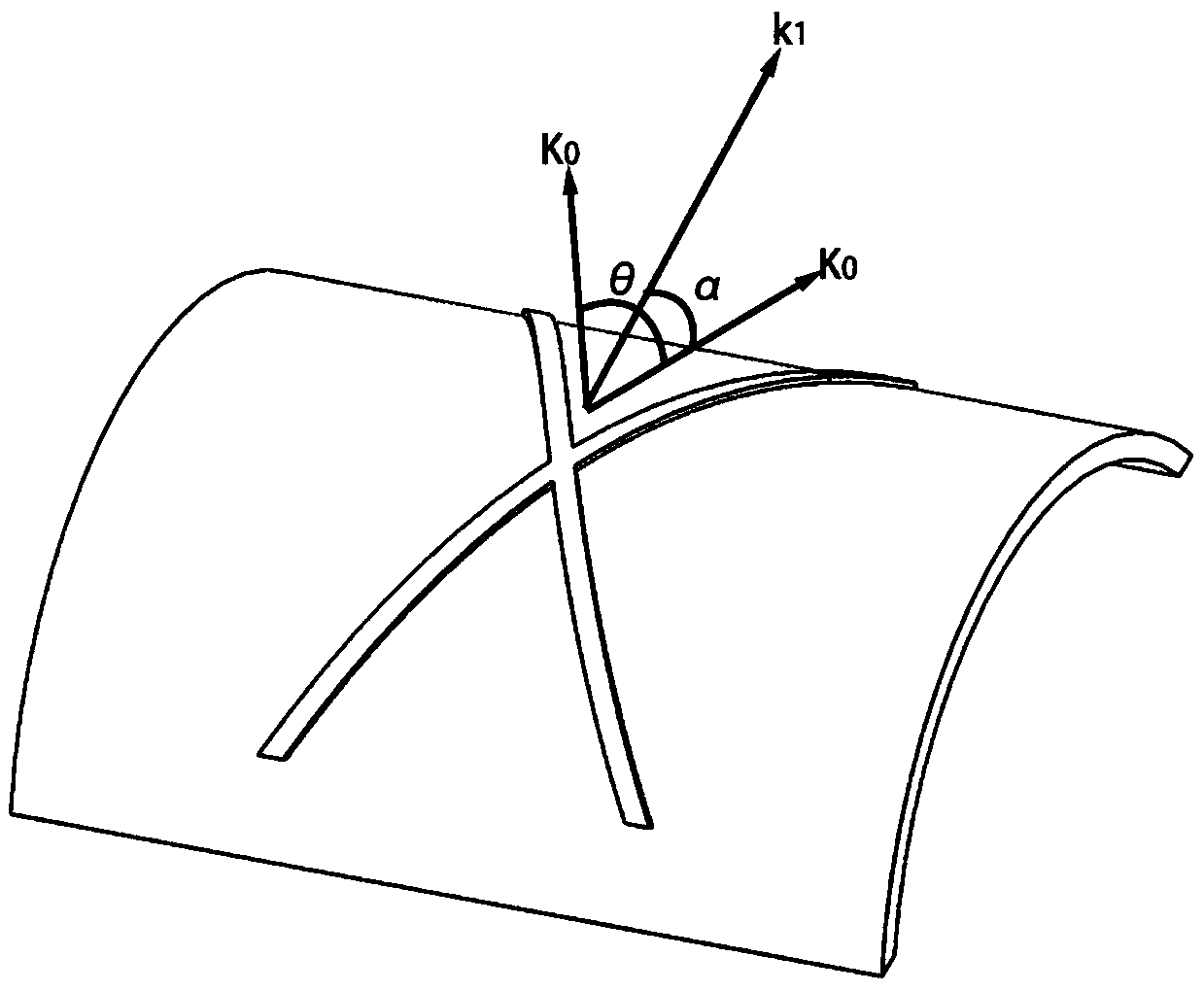

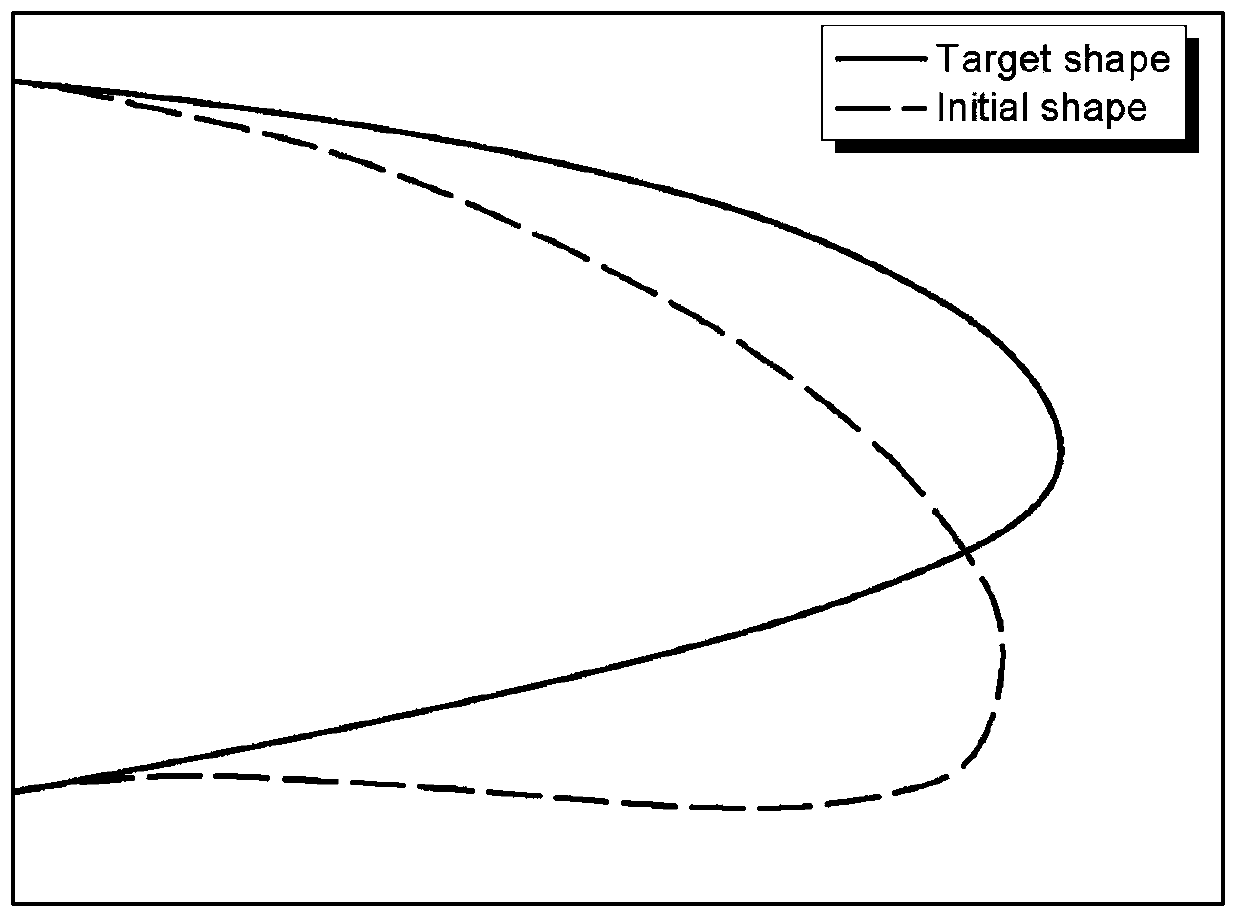

Deformation-controllable four-dimension (4D) printing method for composite material embedded with continuous fiber

ActiveCN108943701AAchieve deformationHigh deformation accuracyAdditive manufacturing apparatus3D object support structures4d printingMATLAB

The invention provides a deformation-controllable four-dimension (4D) printing method for a composite material embedded with a continuous fiber. The printing method comprises the steps that the principal curvature and the principal curvature line of a to-be-deformed curved plane are solved; then fiber trajectory is solved through the length-keeping and transforming theory and differential geometrytheory; planning is conducted on the fiber trajectory, a solution is acquired through a Matlab software, and route points passed by the fiber in the printing process are acquired; a bottomed resin material is printed first; then a top material formed by the resin and a fiber distributed along route trajectory is printed; heat treatment is conducted on the material acquired from printing; and thecomposite material can be deformed into an expectant shape. According to the deformation-controllable 4D printing method for the composite material embedded with the continuous fiber, controllable deformation of any developable curved plane shape can be achieved; and because of high controllability of fiber orientation, the composite material is provided with quite high deformation precision.

Owner:深圳协同创新高科技发展有限公司

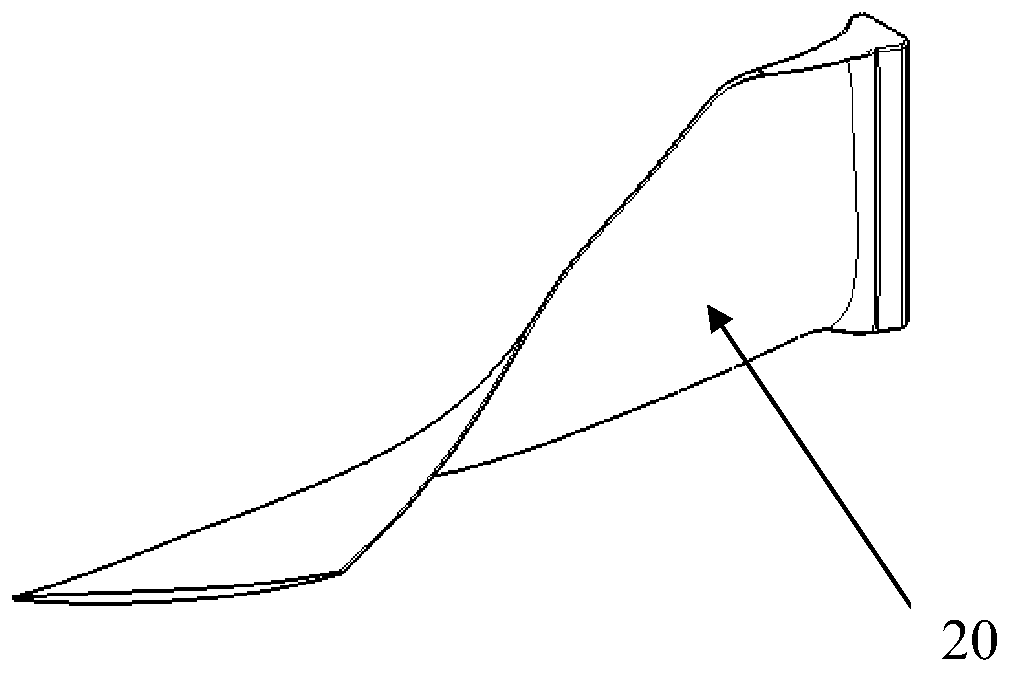

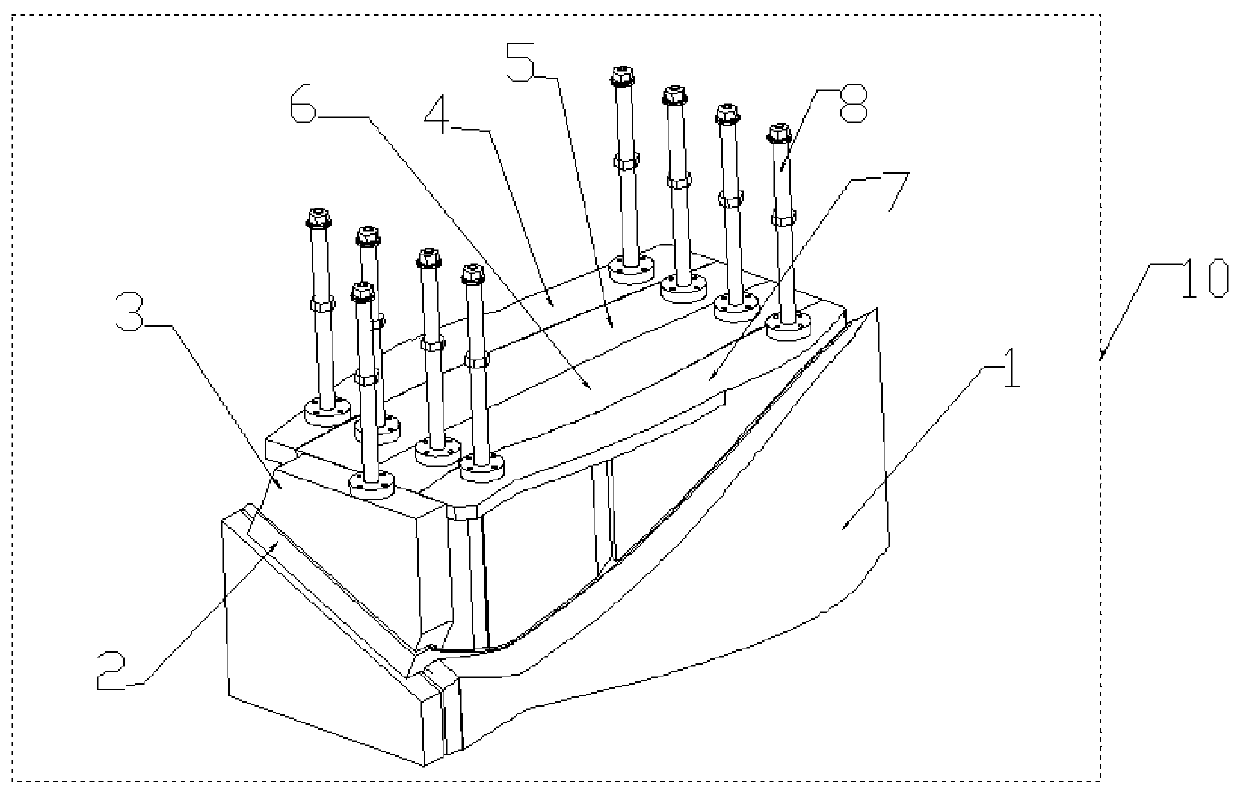

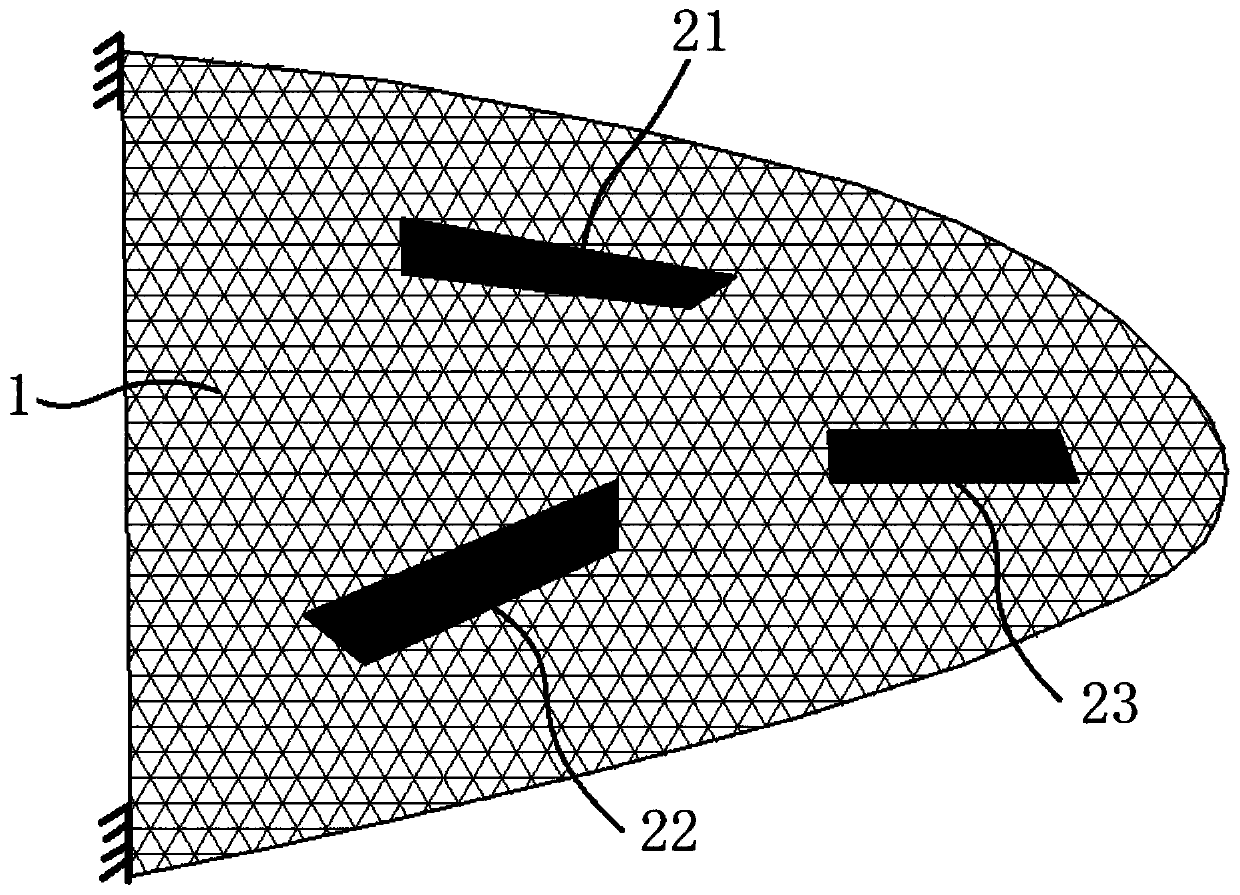

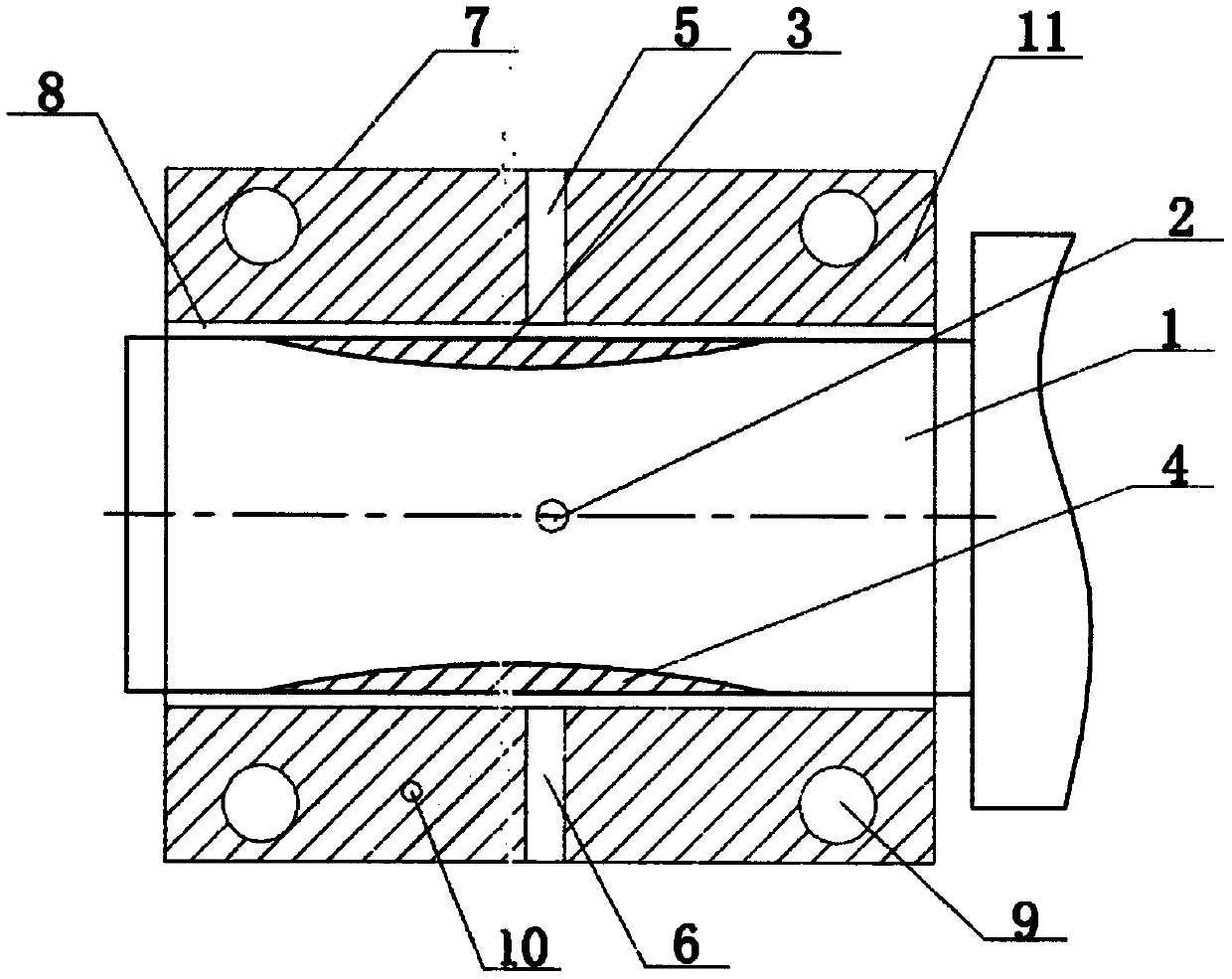

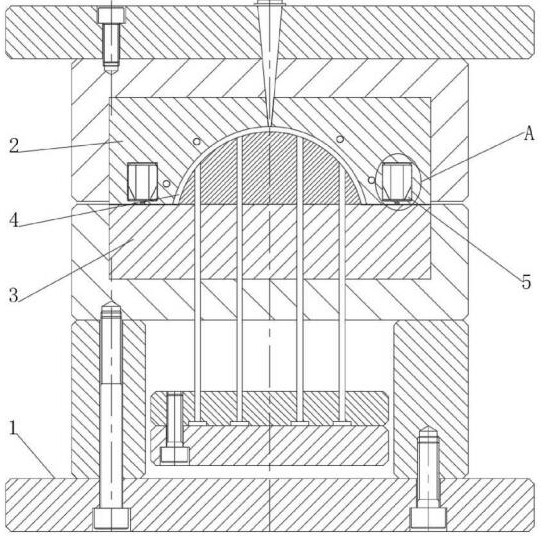

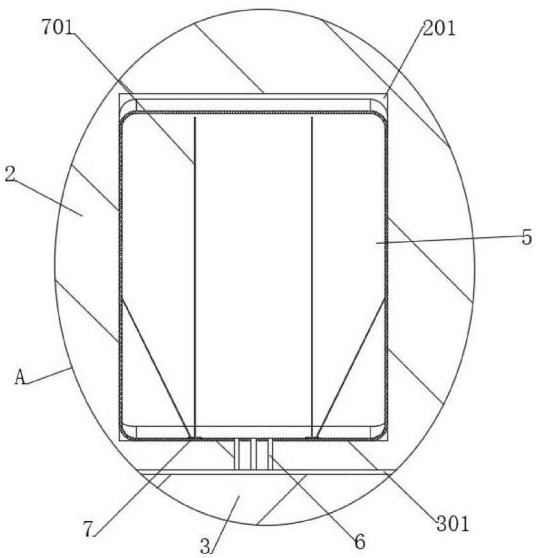

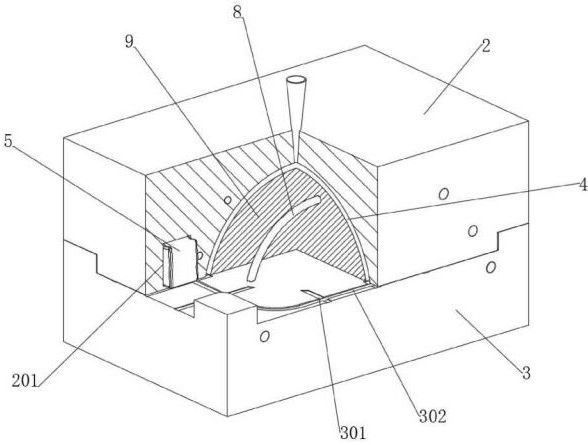

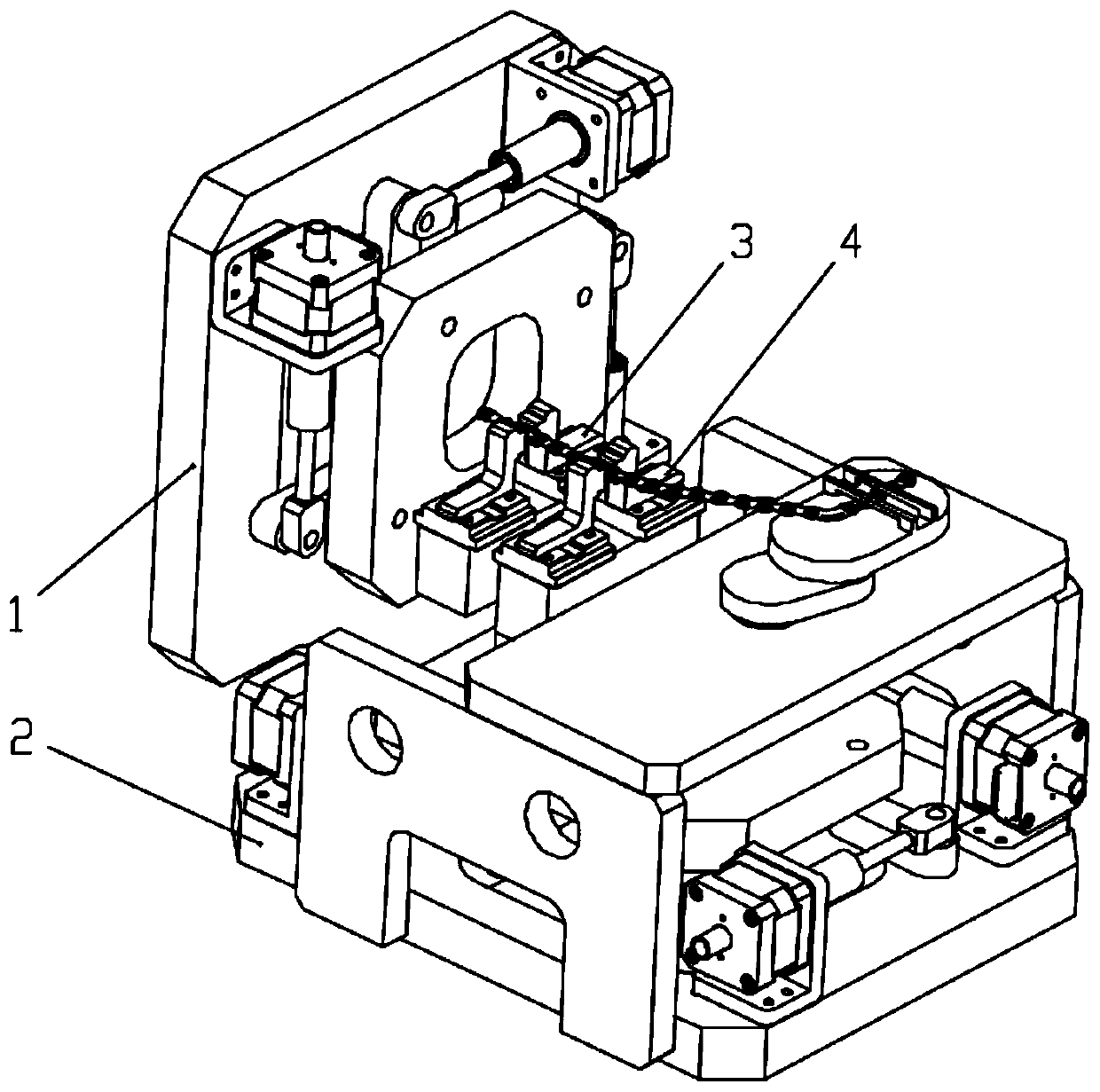

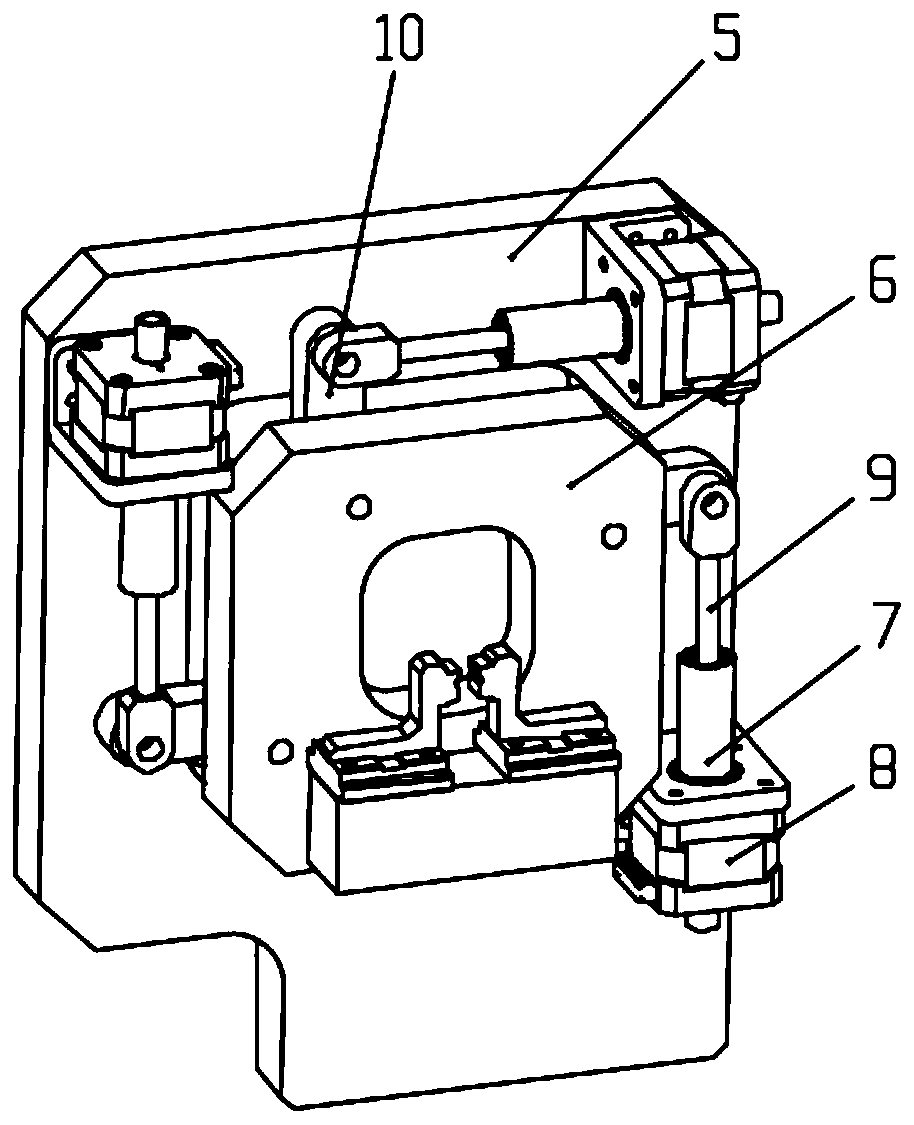

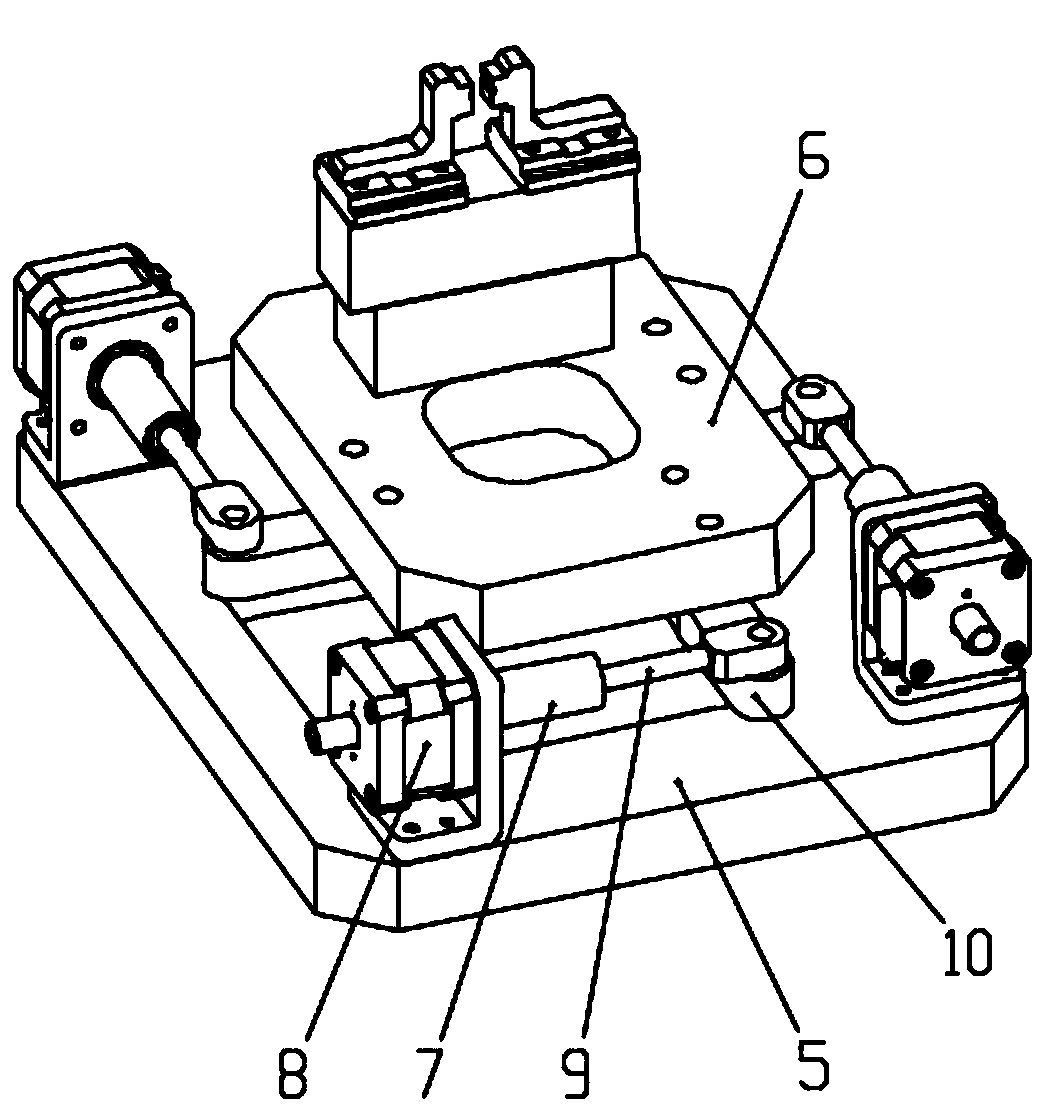

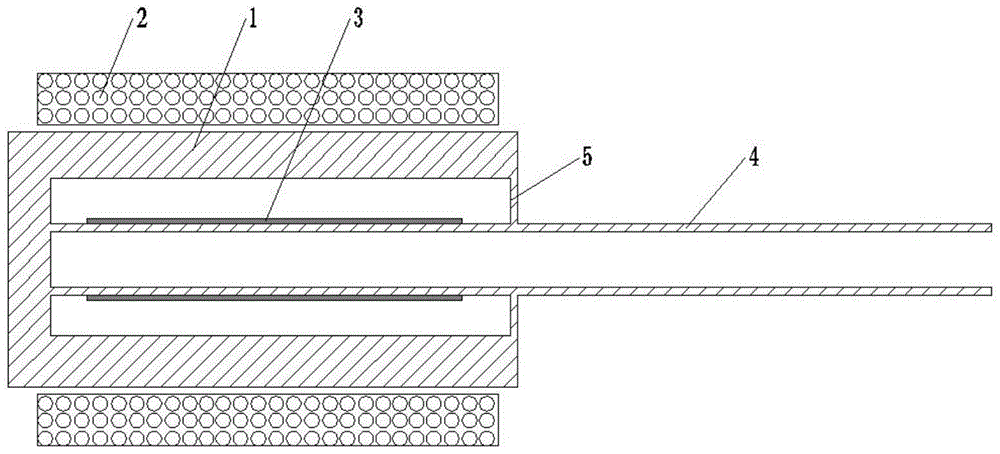

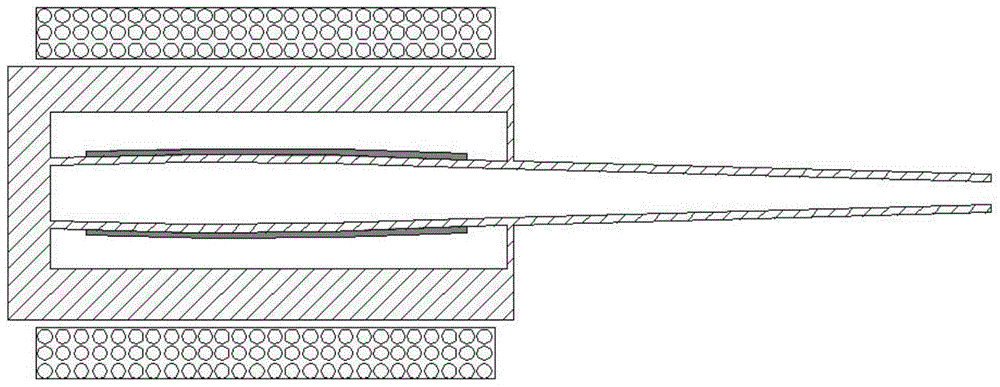

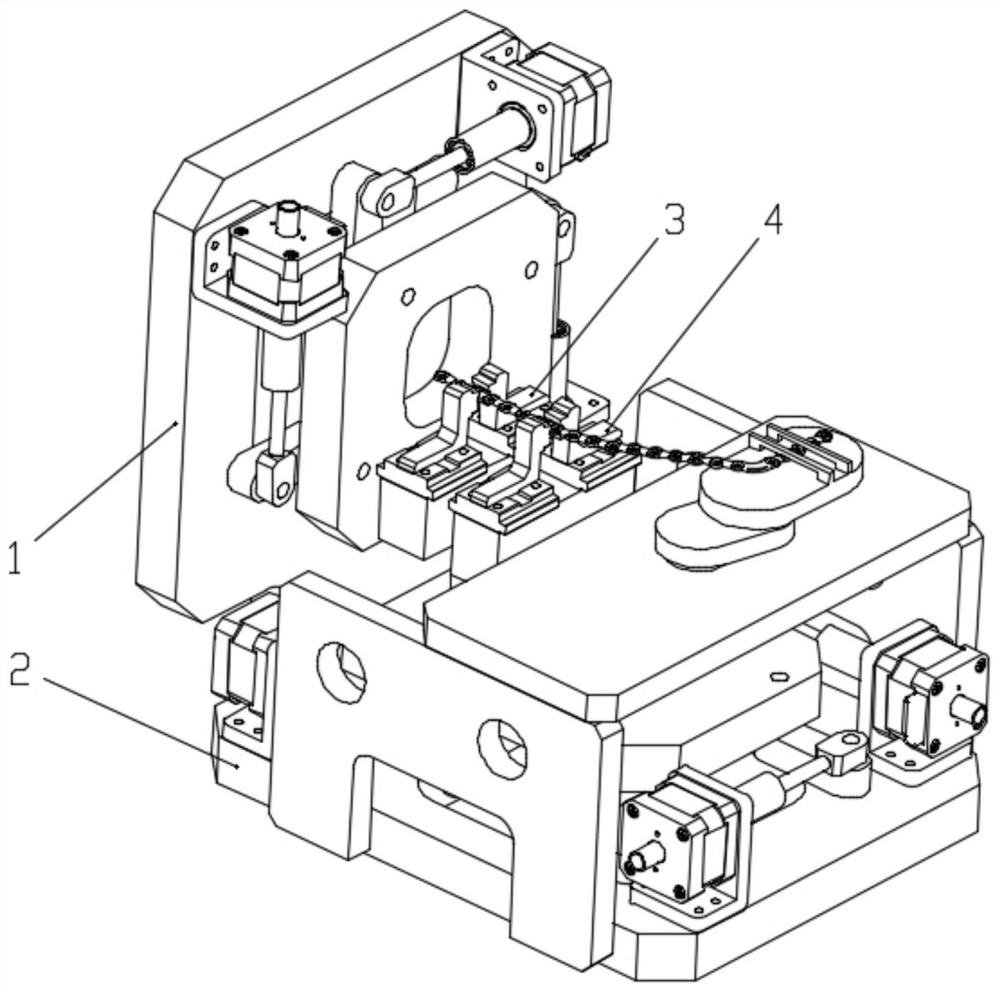

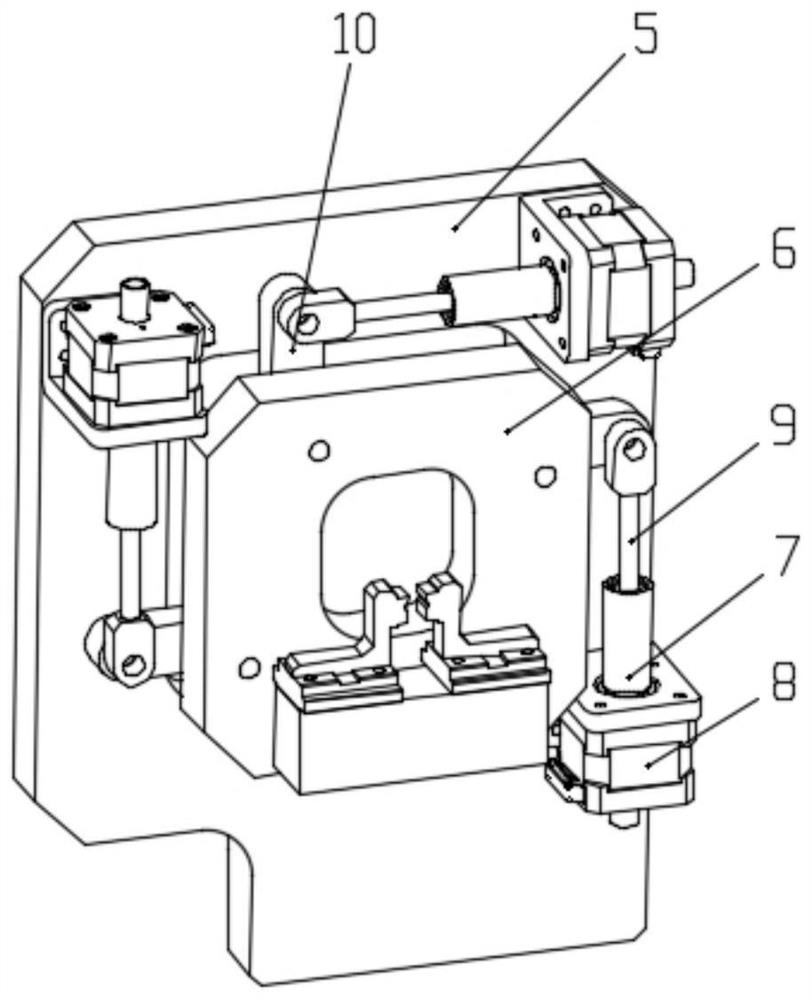

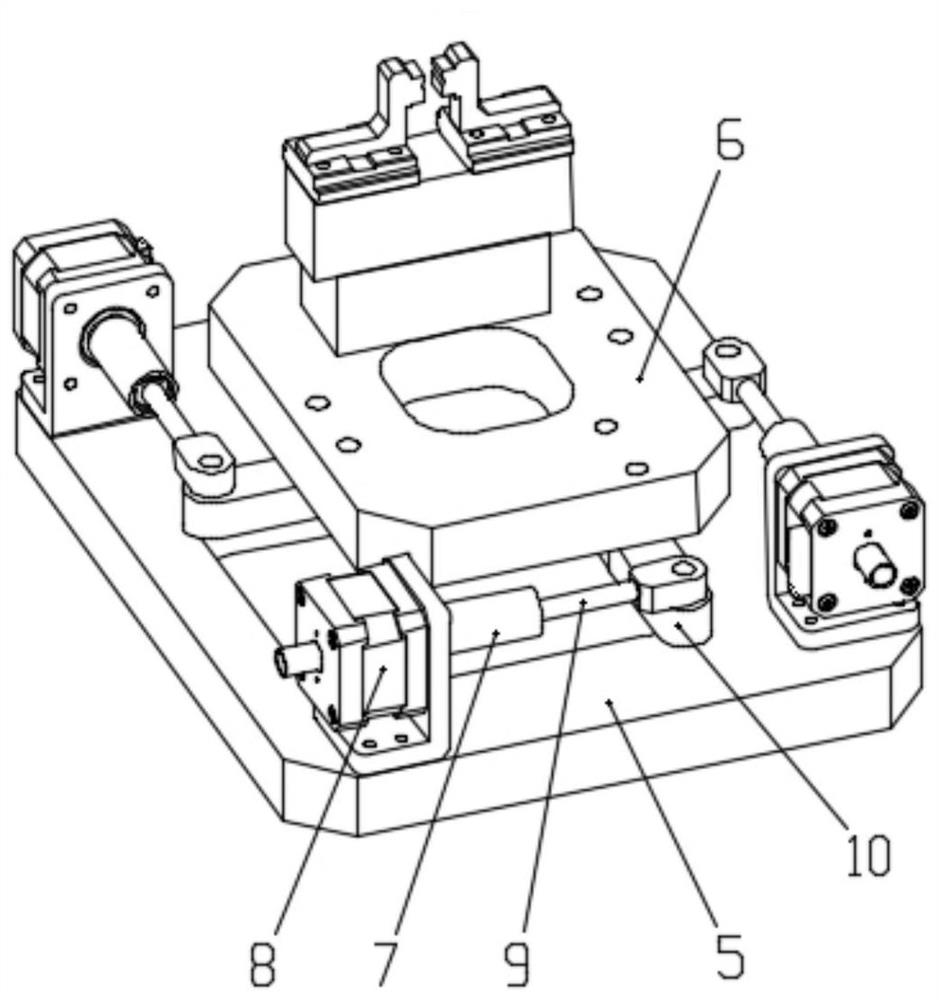

Forming device and method for twisted variable-thickness composite material structure

The invention belongs to a forming technology for a resin matrix composite material preform, and specifically relates to a forming device and method for a twisted variable-thickness composite materialstructure. Due to insufficient machining accuracy for a preform and a limit of a weaving process, a difference exists between the thickness of the weaved preform of a blade and a theoretical thickness of the blade, and the phenomena of secondary bonding and compaction with a molded surface, of the preform, exist in a die assembly process. The forming device for the twisted variable-thickness composite material structure comprises a base, a transversal press block and a longitudinal block, wherein the upper surface of the base is the same as the lower surface of the twisted preform, the combined lower surface of the transversal press block and the longitudinal block is the same as the upper surface of the twisted preform, and accurate deformation control over the variable-thickness preformof the blade from a planar state to a twisted state is realized, so that the deformation accuracy is remarkably increased, and the deformation process is controllable; and the problem of local extrusion or slide deformation which is brought by simultaneous compression of preforms in areas with different thicknesses, is avoided.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

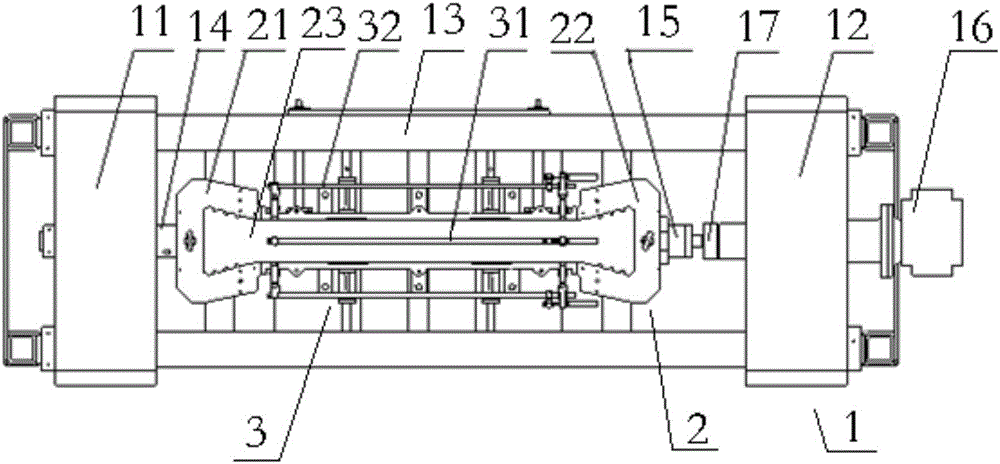

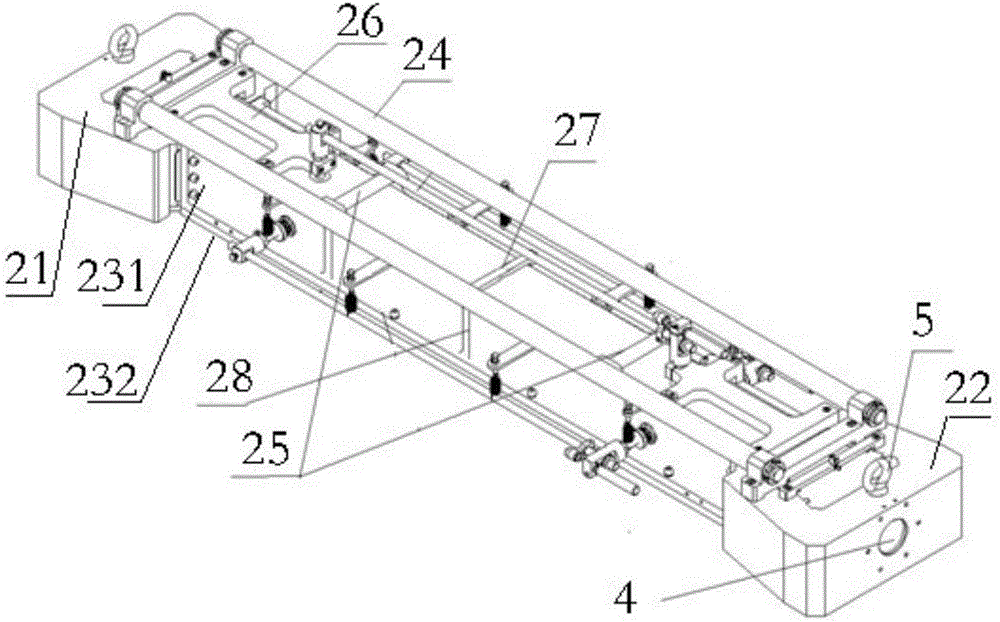

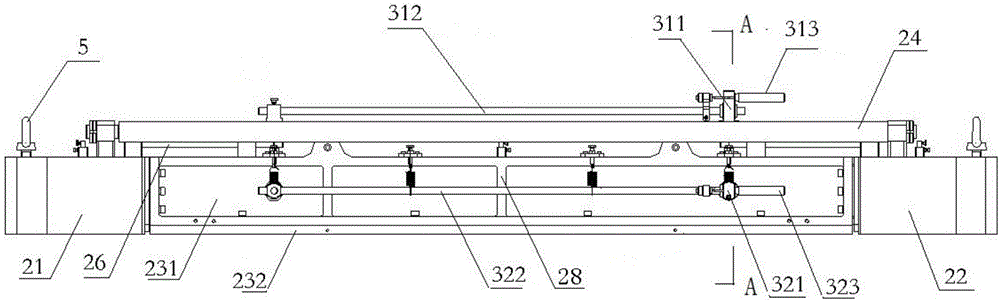

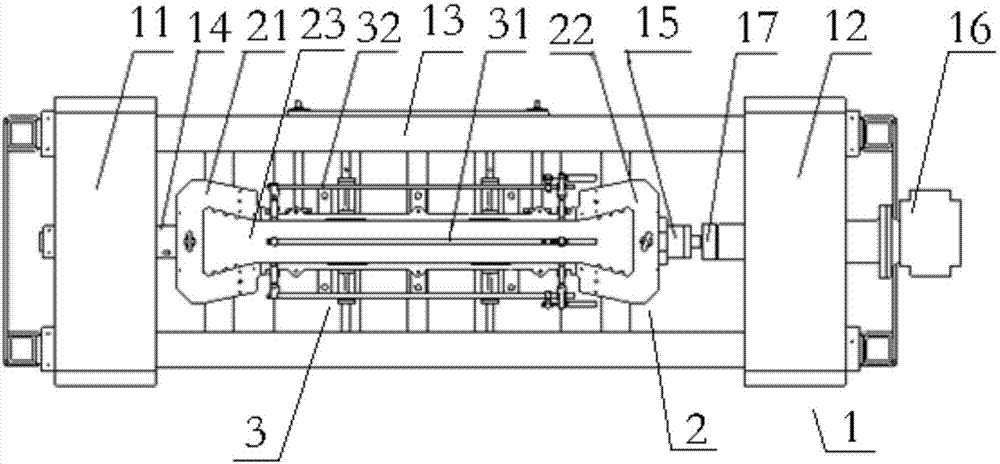

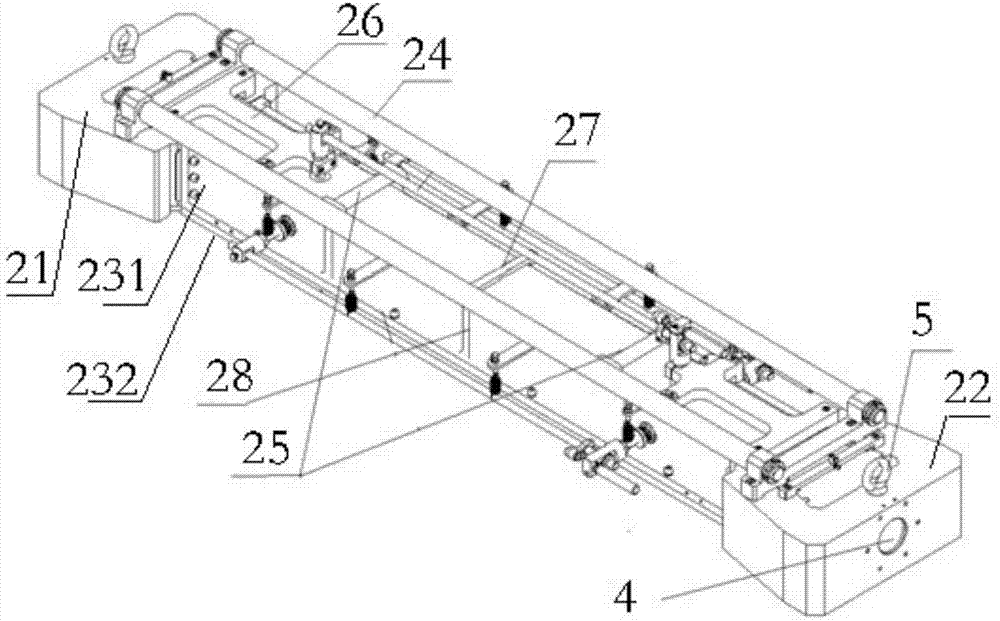

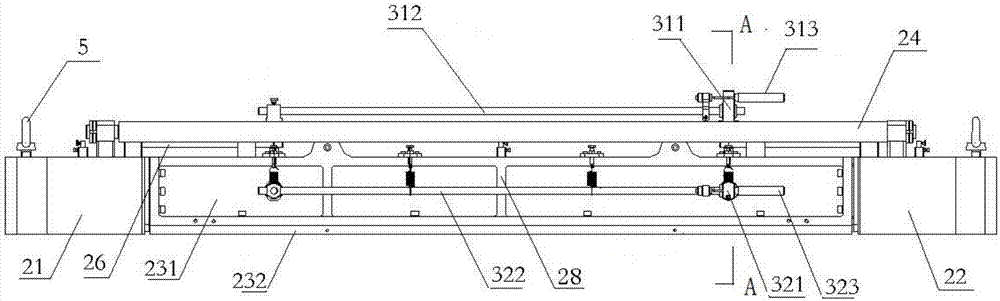

Concrete temperature stress testing machine achieving mold separable vibrating

ActiveCN106248914AImprove pouring qualityHigh deformation accuracyPreparing sample for investigationMaterial testing goodsTemperature stressMeasurement device

The invention discloses a concrete temperature stress testing machine achieving mold separable vibrating. The testing machine comprises a main testing machine body, a concrete sample mold detachably connected with the main testing machine body, and a deformation measurement device. According to the concrete temperature stress testing machine achieving mold separable vibrating, mounting and demounting of the concrete sample mold and the main testing machine body are convenient, the concrete sample mold can be independently poured and vibrated after being demounted, the concrete sample mold is mounted on the main testing machine body for relevant temperature stress testing after the vibrating quality requirement is met, the pouring quality of concrete is greatly improved, and the credibility and comparability of the test result are better.

Owner:TSINGHUA UNIV +1

Multiple contact-point flexible bearing applicable to a harmonic drive

InactiveUS20200040981A1Low additional deformationReduces bend deformationRoller bearingsGearingLubricationHarmonic drive

A multiple contact-point flexible bearing applicable to harmonic drive has three contact-point flexible ball bearing, four contact-point flexible ball bearing and line contact flexible roller bearing. Single rolling element has two or two more contact points with the outer ring raceway, i.e. outer ring—flexspline interference fit component. Deformation accuracy of outer ring—flexspline interference fit component and teeth meshing accuracy of flexible and rigid wheels are improved so unnecessary additional deformation is reduced and even avoided. Contact stress between rolling element and raceway is reduced. Slip of rolling element is controlled. Quality and technical advantages such as bearing assembly conditions and lubrication conditions in operation are enhanced. Eventually, operating accuracy and service life of the flexible bearing, flexspline even the whole harmonic drive are improved, which means a lot in practical engineering.

Owner:SHANGHAI F&S BEARING TECH

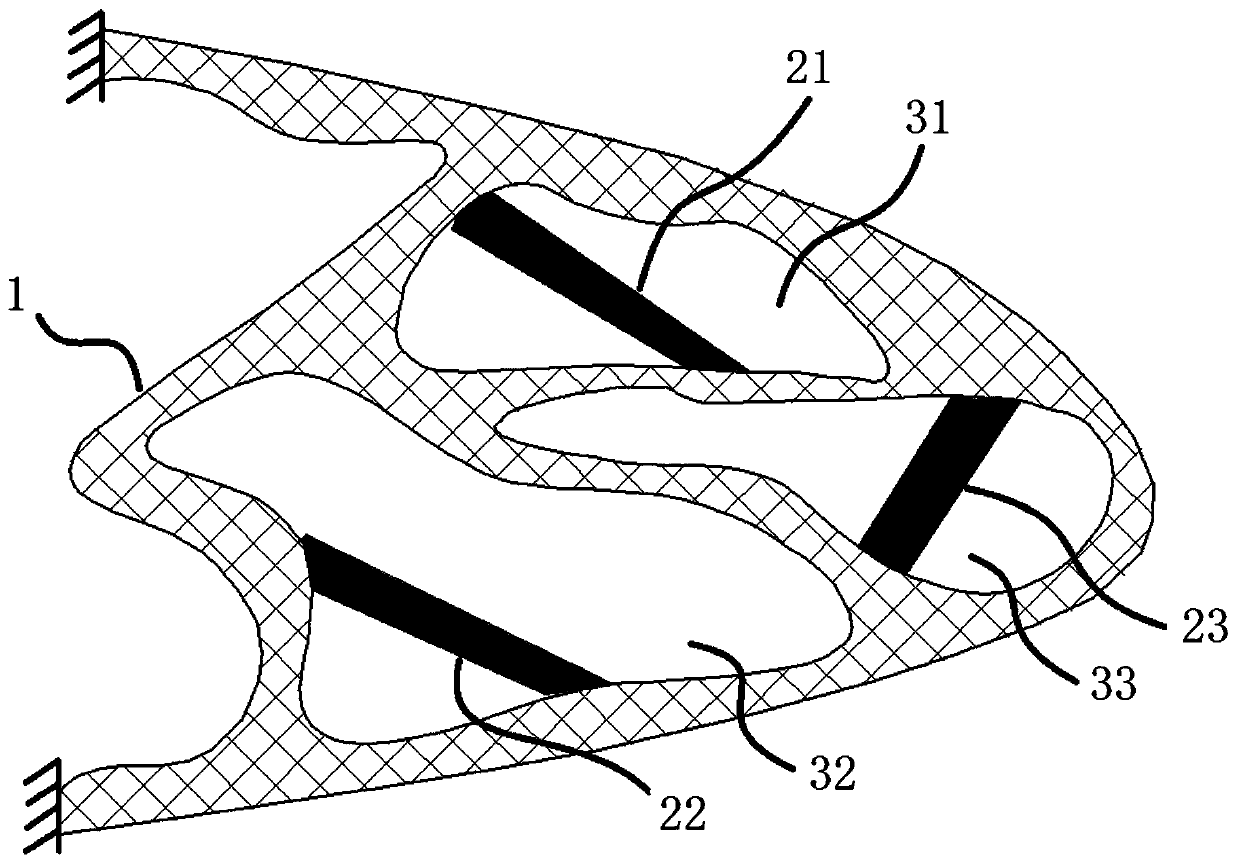

Flexible leading edge structure and design method thereof

ActiveCN111409815AGet Aerodynamic Performance RequirementsRealize integrationSustainable transportationWing adjustmentsLeading edgeEngineering

The invention provides a flexible leading edge structure. The structure comprises a flexible structure which is used for forming an aerodynamic configuration of a wing leading edge, and driving structures which are arranged in the flexible structure in a distributed mode and can generate driving force under excitation of excitation signals, wherein the driving force acts on the flexible structureto change the aerodynamic configuration of the flexible structure. Compared with an existing variable camber wing leading edge device, the flexible leading edge structure is advantaged in that on onehand, true integration of the structure and functions can be achieved, the driving structure can serve as a driver and can further serve as a bearing structure, structural complexity can be effectively reduced, the weight can be reduced, and comprehensive performance of an airplane can be improved; on the other hand, deformation precision can be improved through the multiple driving mechanisms arranged in a distributed mode, deformation control over the multiple target configurations can be further achieved, and real-time optimization of the front edge configuration is truly achieved.

Owner:CHINA AIRPLANT STRENGTH RES INST

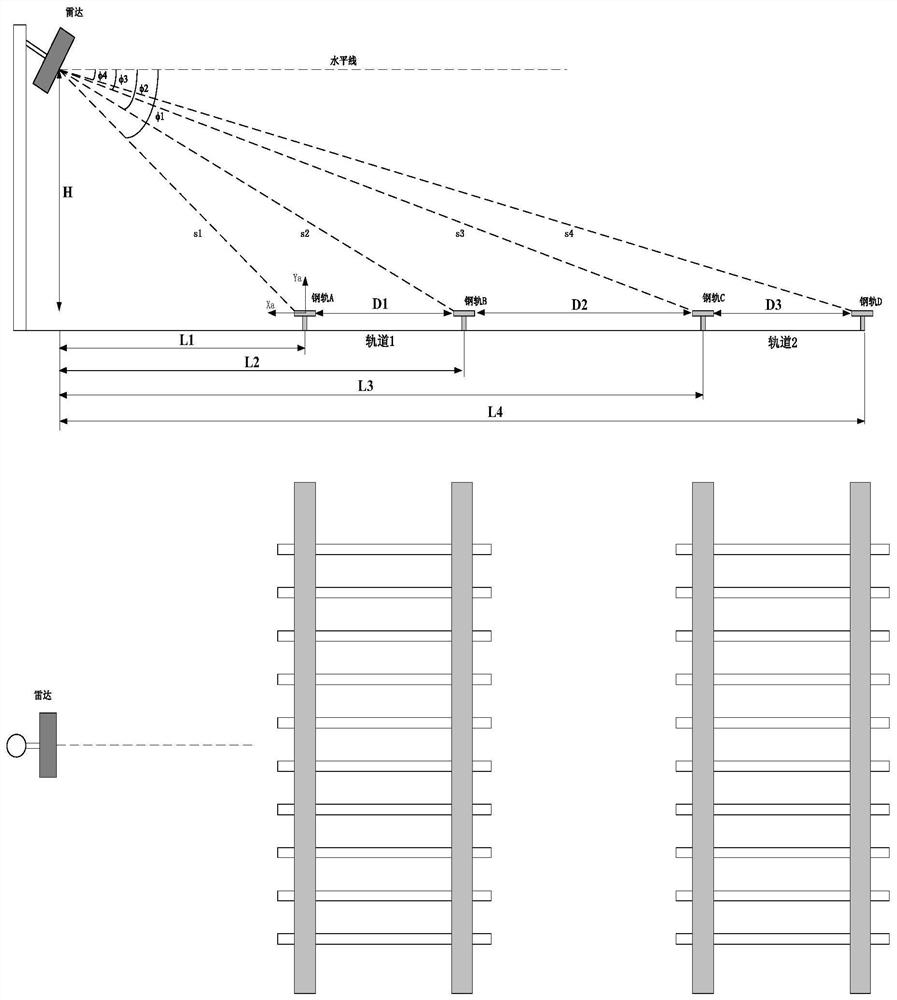

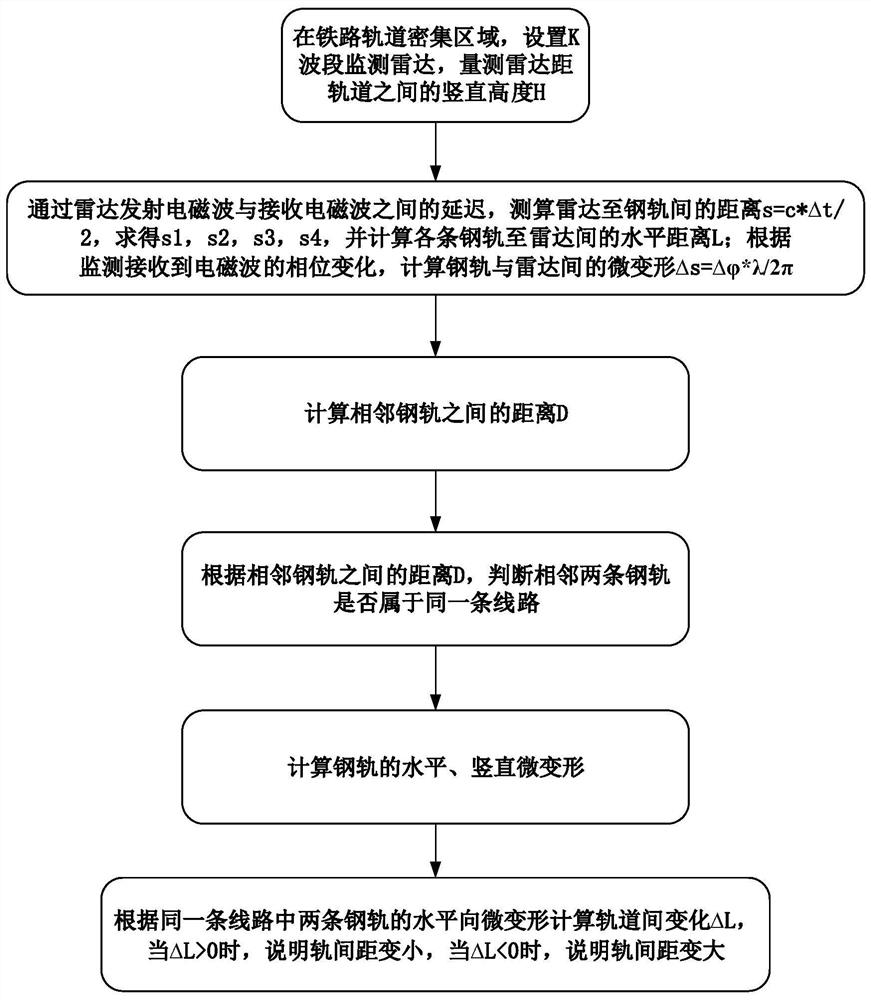

K-band radar-based track non-contact deformation high-precision measurement method

PendingCN112485790AAchieve deformationRealize deformation monitoringUsing wave/particle radiation meansRailway auxillary equipmentRadarTrackway

The invention discloses a K-band radar-based track non-contact deformation high-precision measurement method. The method comprises the following steps of: fully utilizing a means of combining K-band radar absolute distance measurement and phase detection to respectively determine the distance from a K-band radar to a steel rail and the displacement deformation of the steel rail, measuring the distance s from the radar to the steel rail according to the delay between electromagnetic wave emission and electromagnetic wave reception of the radar, then monitoring the phase change of the received electromagnetic wave to obtain the real-time change of the monitored steel rail and the micro-deformation from the steel rail to the center point of the radar, and then obtaining the micro-deformationof a track by calculating the horizontal and vertical components of the micro-deformation of the steel rail and the center point of the radar. According to the method, all-weather track deformation monitoring is achieved, steel rails of different tracks can be automatically distinguished for a plurality of railway track concentration areas, the high-precision measurement characteristic and the portability characteristic of the K-band radar are fully utilized, and the measurement precision of track deformation monitoring is improved.

Owner:HUNAN ZHONGDA CONSTR ENG TESTING TECH +1

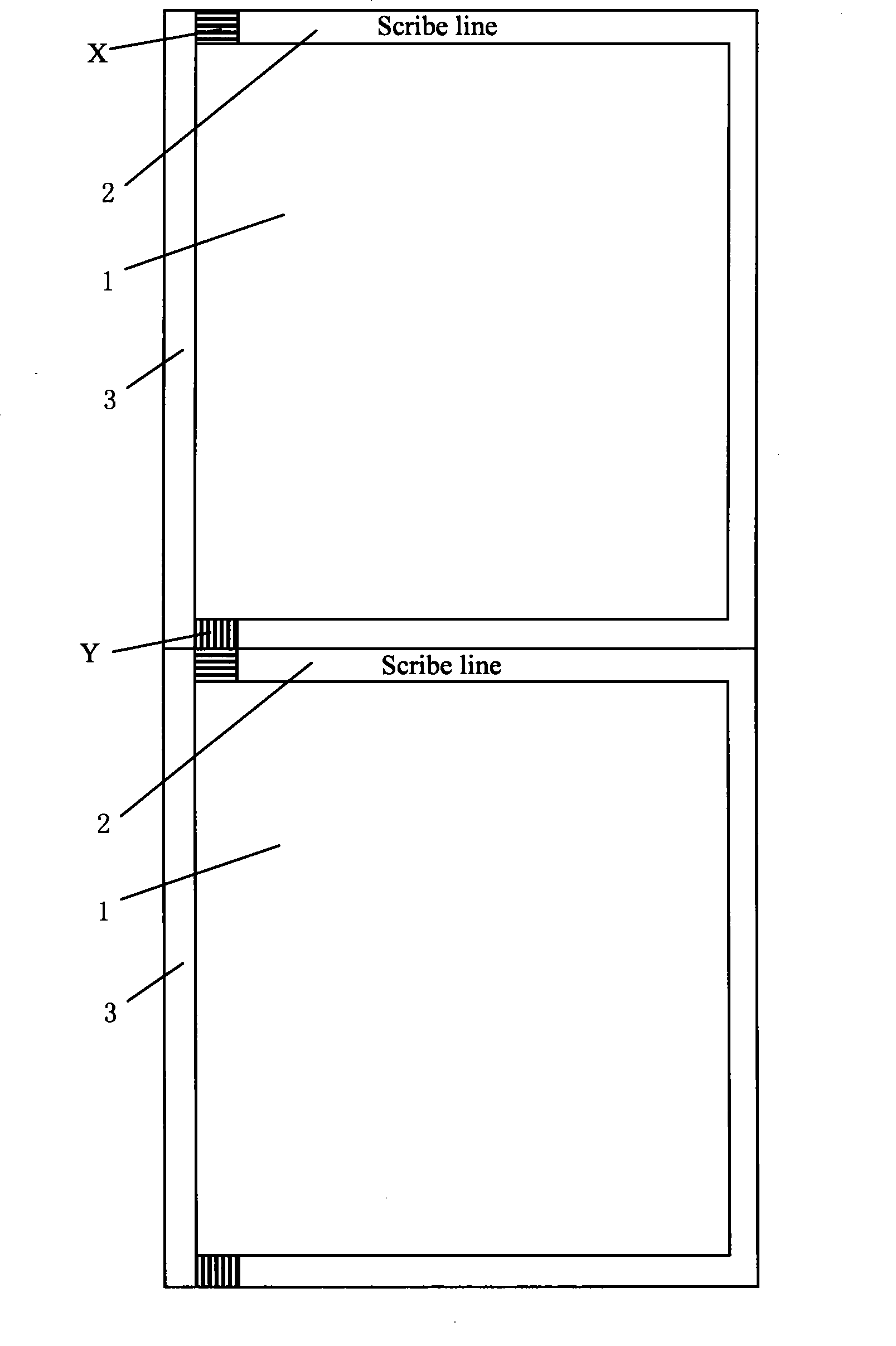

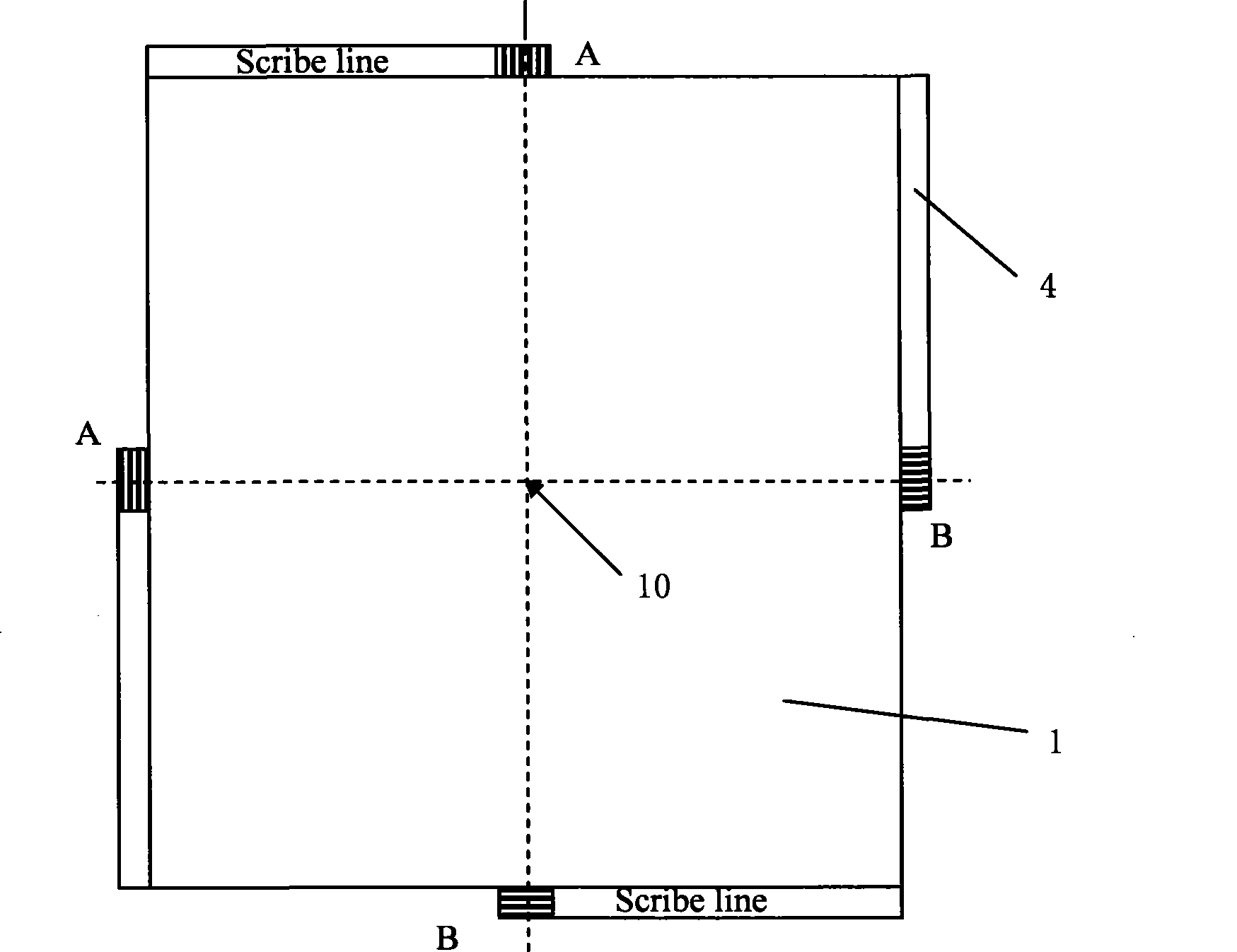

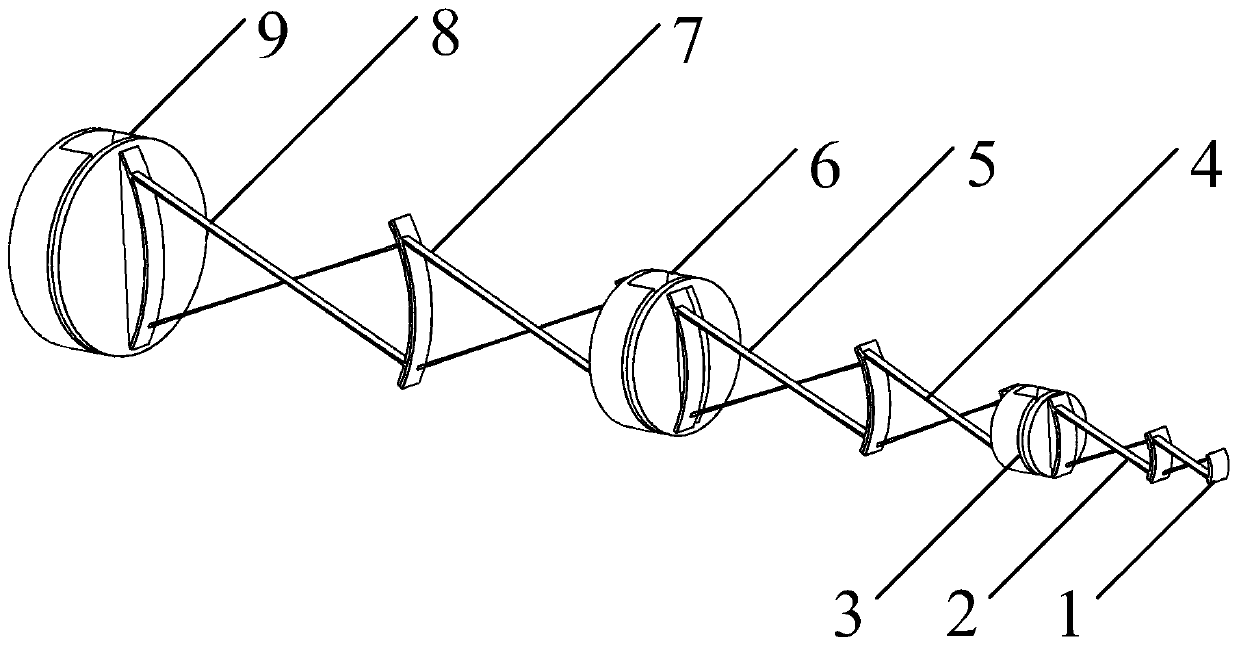

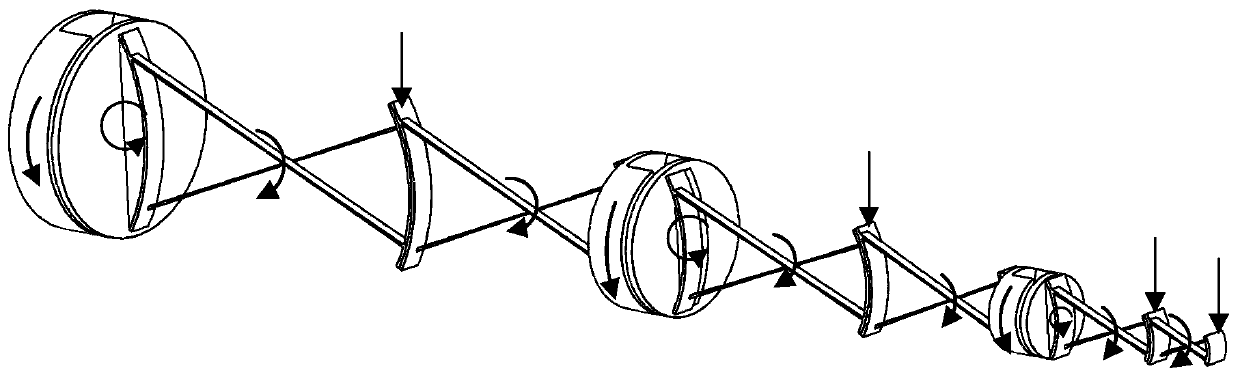

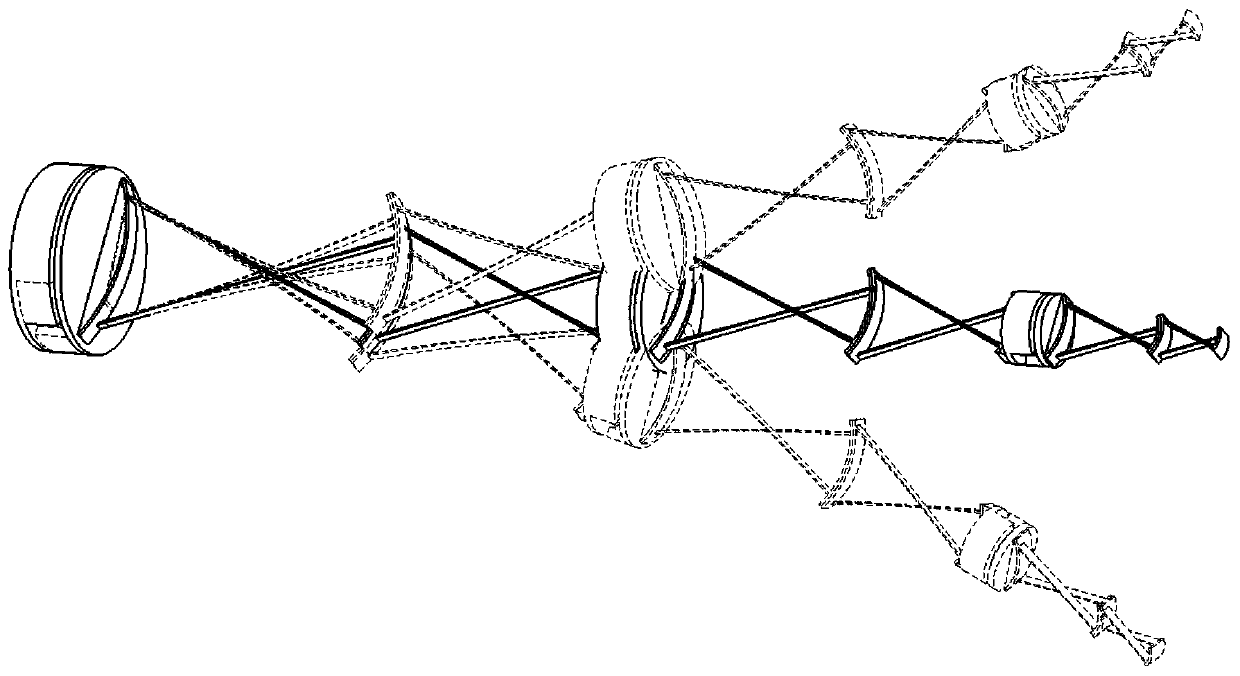

Lithography layout and method for measuring lithography deformation thereof

ActiveCN101750899BHigh deformation accuracyReduce the ratioSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusMechanical engineeringSilicon

The invention discloses a lithography layout, comprising an exposure unit, wherein four edges of the exposure unit are provided with a cutting street respectively; each cutting street is arranged in windmill shape; and the tail end of each cutting street is provided with a rotation mark which is aligned to the center of the exposure unit. The four rotation marks can be divided to two types, one is frame shape, and the other is rectangular shape. Two different rotation marks are arranged at the tail ends of the cutting streets, and can be measured through a machine aligning precision measurement in the current technical process without adding new machines. The lithography layout determines the deformation condition of first lithography through measuring two rotating marks so as to improve the deformation precision of the first lithography. The length and width of the cutting street are only half of the length and width of the cutting street in the prior art, so that the proportion of the dimension of the cutting street on a silicon wafer can be greatly shortened. The invention also discloses a method for measuring lithography deformation by adopting the lithography layout.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

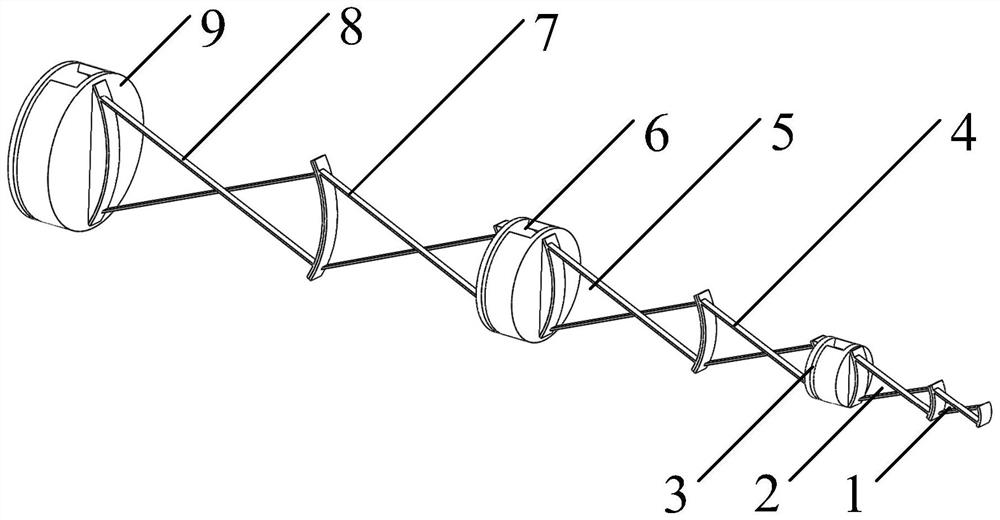

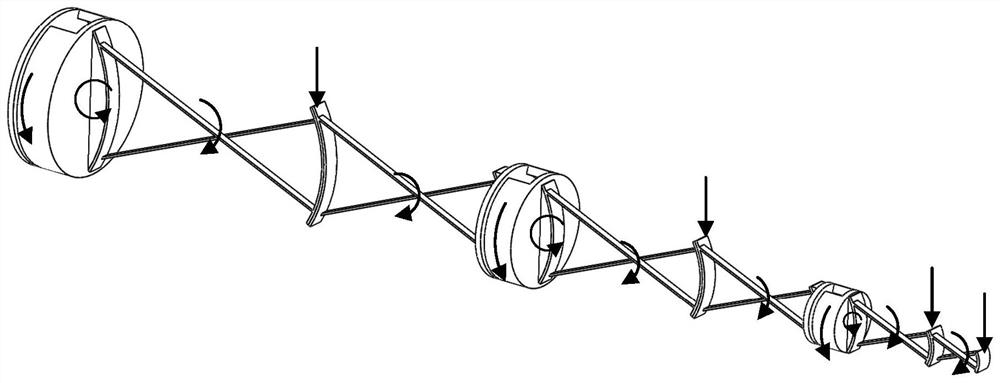

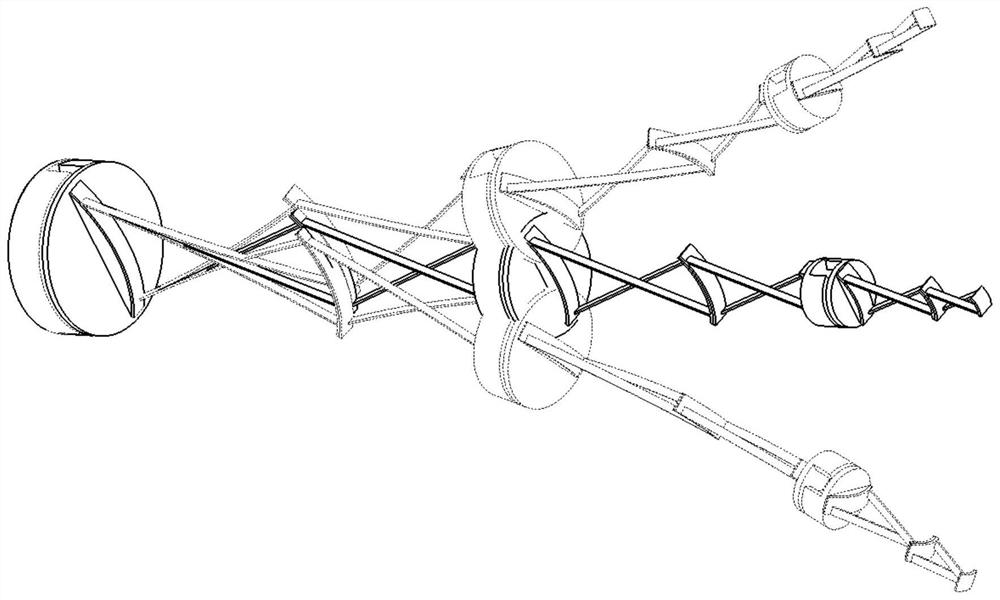

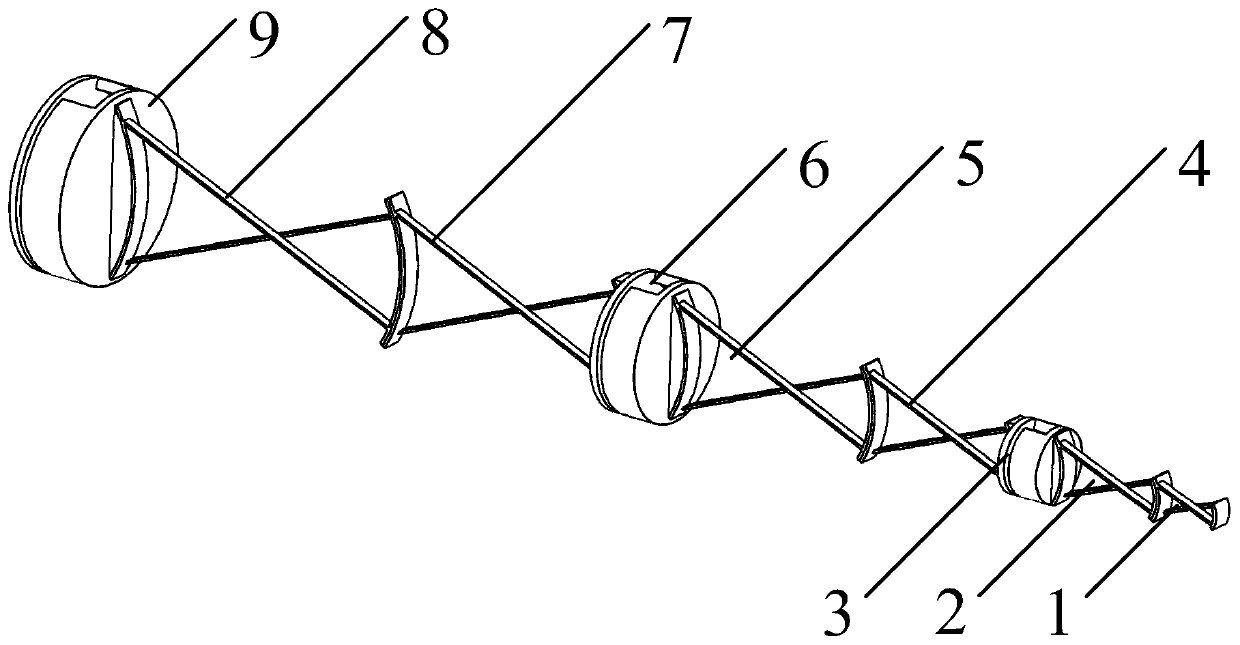

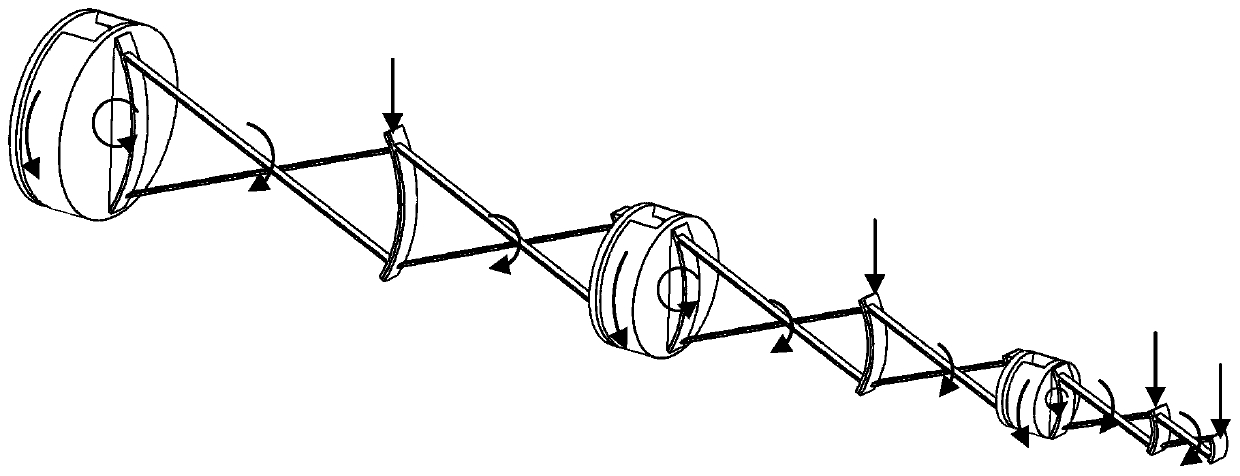

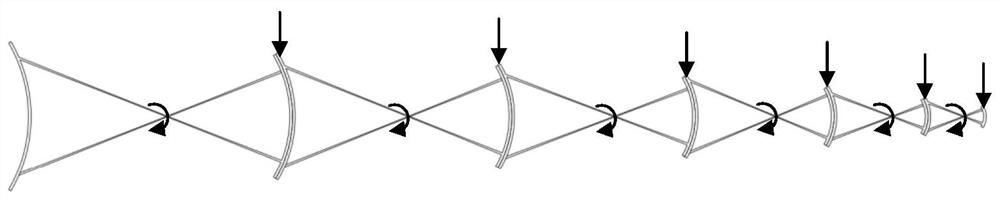

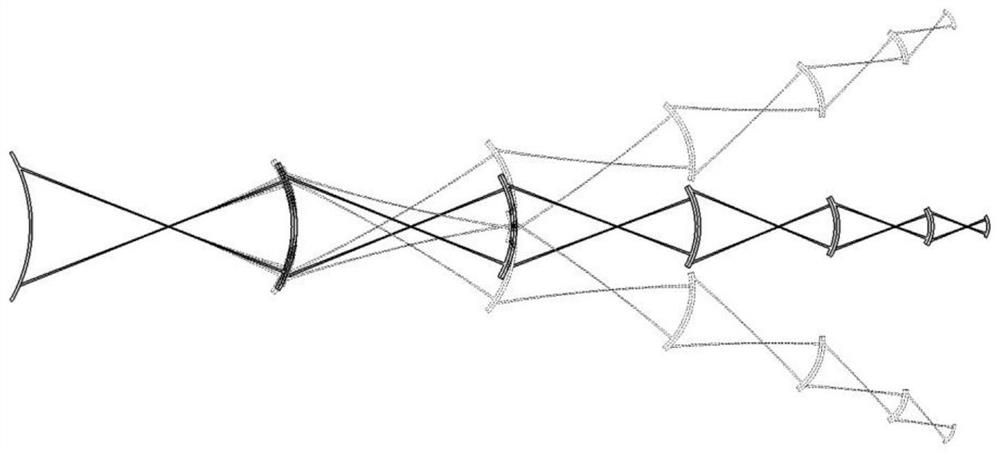

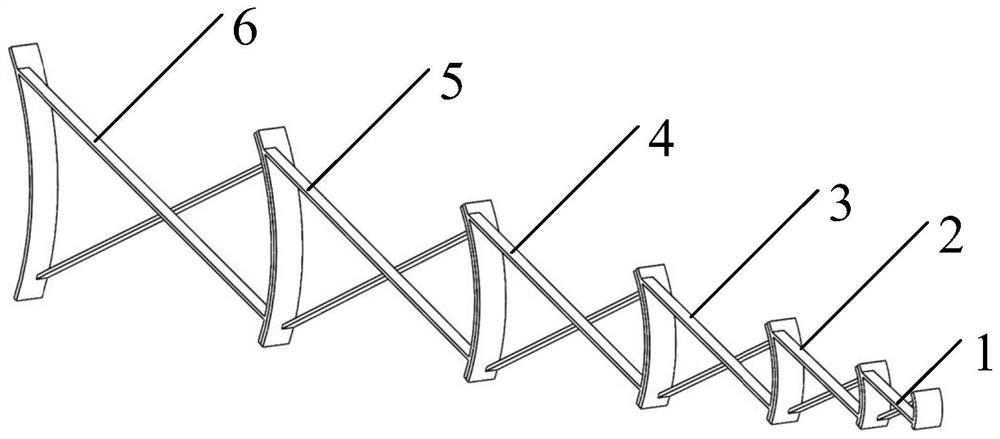

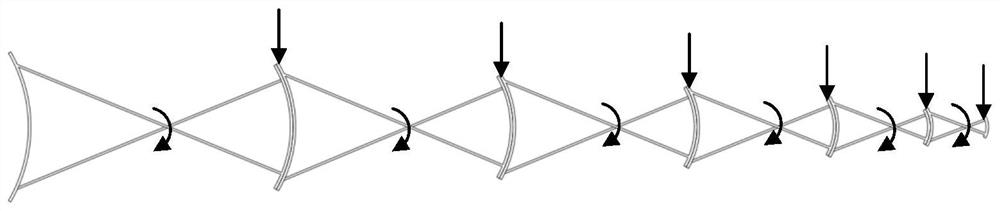

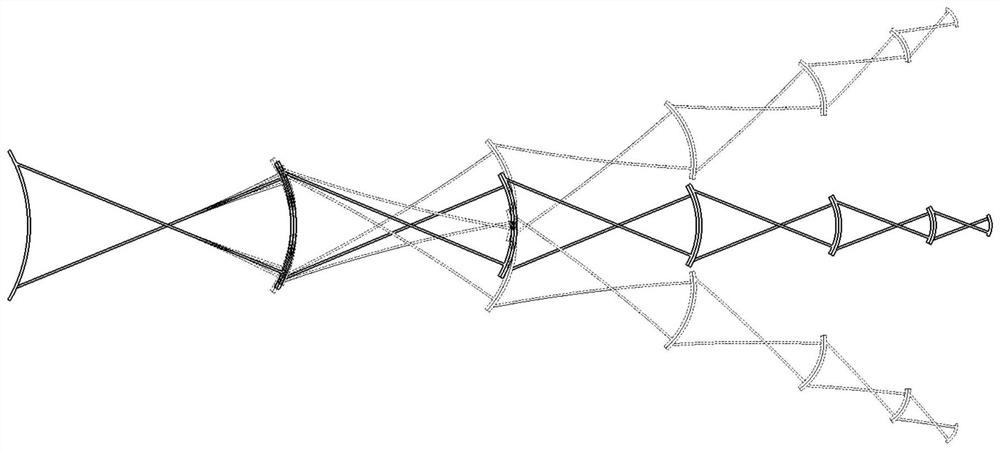

Passive bending and axial rotating mechanism based on cross reeds with variable cross sections

ActiveCN110525620AReduce offsetHigh deformation accuracyPropulsive elements of non-rotary typeLubricationEngineering

The invention relates to a passive bending and axial rotating mechanism based on cross reeds with variable cross sections. The whole multistage passive bending and axial rotating mechanism consists ofa plurality of cross reed units of different sizes and types, cambered free ends are adopted for units bearing passive bending, and the cross points of the cross reeds are overlapped with the cross reed units relative to the circle center of the free end on the outer side of the whole bending mechanism, so that the offset of the cross point of each cross reed unit is reduced when each cross reedunit is subjected to passive bending deformation, and the deformation precision of each cross reed unit is higher. The cross reeds adopt the cross reed units with the variable cross sections, and thecross section of each reed is thinnest at the corresponding cross point and thickest at the portion connected with the free end, so that the large passive deformation is realized under the condition of ensuring the deformation precision. The mechanism has the advantages of high precision, no friction, no lag, no wear, no stiction, no lubrication and the like.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

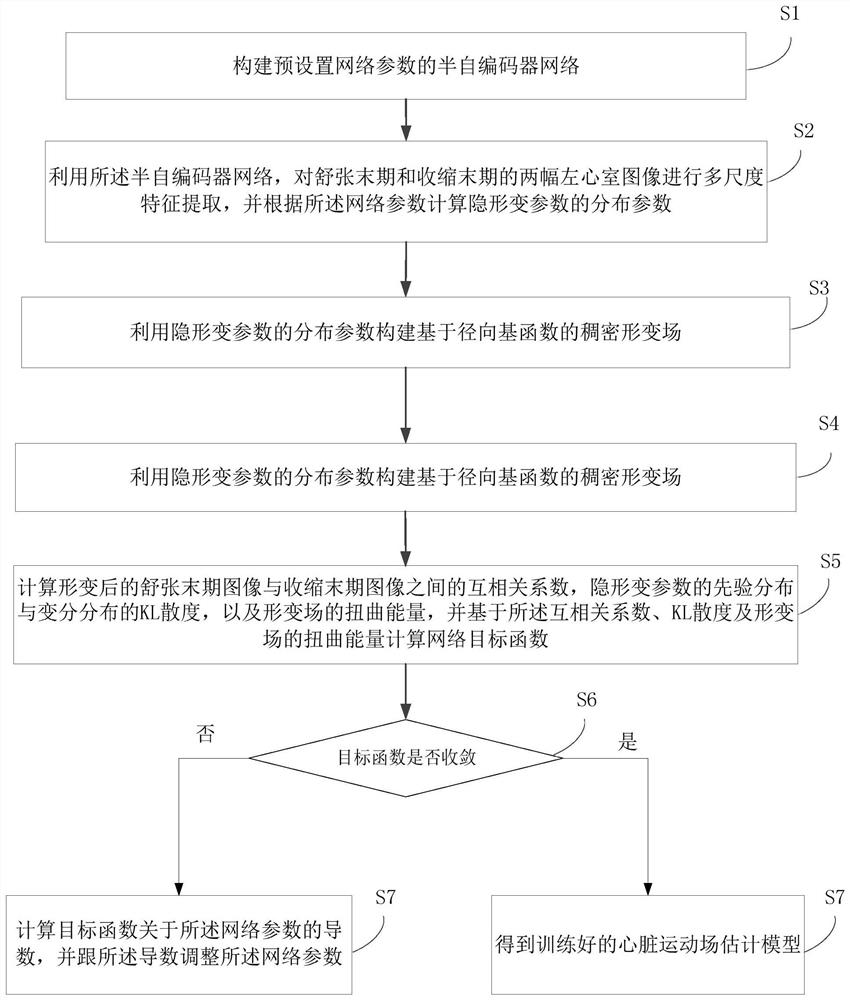

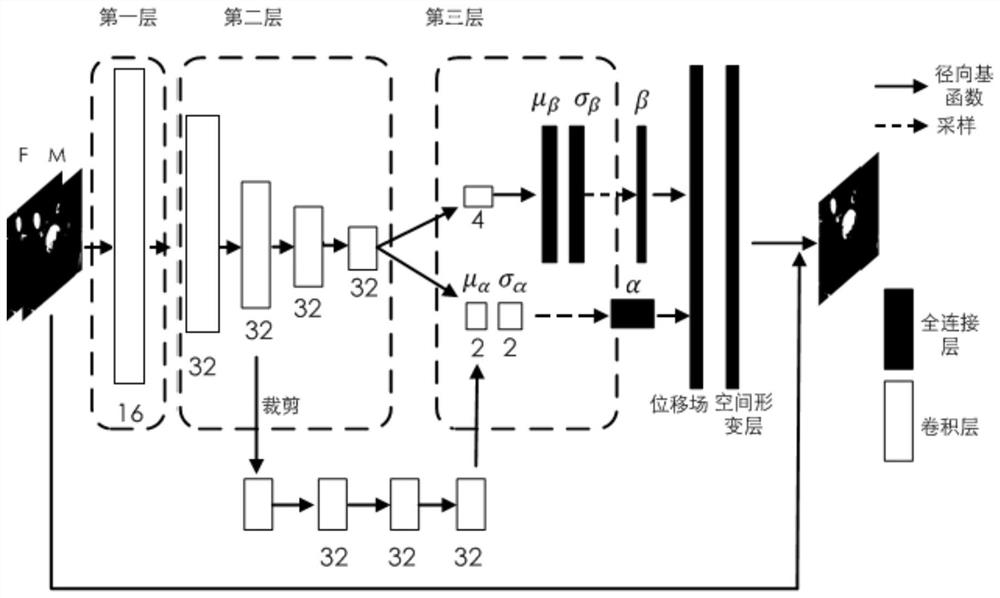

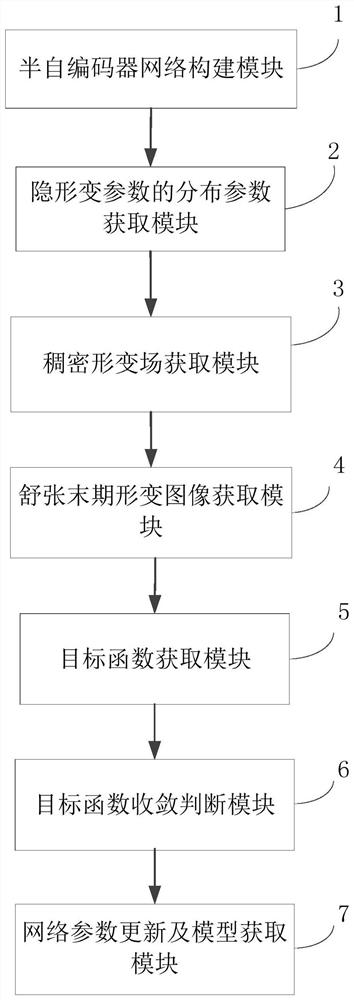

Method and system for training heart motion field estimation model and method and system for heart motion field estimation

PendingCN111784732AOvercome the defect of low estimation accuracyHigh deformation accuracyImage enhancementImage analysisLeft ventricle wallAutoencoder

The invention discloses a method and a system for training a heart motion field estimation model and a method and a system for heart motion field estimation. According to the method and the system fortraining a heart motion field estimation model, a semi-auto-encoder network is used to extract multi-scale features of the left ventricle in a Cine MR images at the end of diastole and the end of systole, different scale features are fused through an encoding network so as to decide distribution parameters of deformation parameters of control points, a deformation model of a radial basis functionis introduced into an auto-encoder, and a decoding process is not needed in an auto-encoder network structure, so that the network is lightened. The non-uniformly distributed control points are adopted, so that the deformation field of the area where the left ventricle is located is easier to control, and the deformation precision is higher; and meanwhile, invisible variable parameters have definite physical significance, the smoothness of a deformation field is easier to control, and a more stable and reasonable heart movement field is obtained to be used for quantitative analysis of cardiovascular diseases.

Owner:SHENZHEN UNIV

Abraded bearing position repairing device

The invention discloses an abraded bearing position repairing device, relates to the bearing abrasion repairing technology field, and especially relates to the abraded bearing position repairing device. The device comprises a bearing installation position, an upper abrasion bearing position, a lower abrasion bearing position, an upper injection hole, a lower injection hole, a grinding tool shell,a repairing layer for an abrasion position, a bolt hole, a positioning hole and a filling portion. The bearing installation position is located in the grinding tool shell, the upper abrasion bearing position is arranged on an upper side of the bearing installation position, the lower abrasion bearing position is arranged on the lower side of the bearing installation position, and the repairing layer for the abrasion position is arranged above the upper abrasion bearing position. After the technical scheme is adopted, the device has advantages that equipment does not need to be disassembled, repair welding is not needed, and disassembling, hoisting and transportation of the equipment can be avoided; machining cost is reduced, and time is shortened; a grinding tool is adopted for forming, heat is not generated, there is no deformation, precision is high, and abrasion resistance is good; and a new shaft does not need to be replaced and cost is low.

Owner:唐山市康泰工贸有限公司

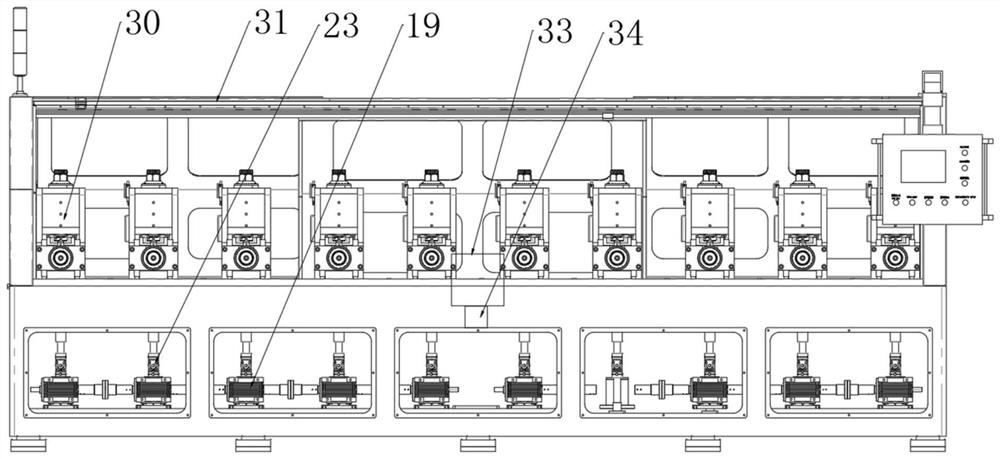

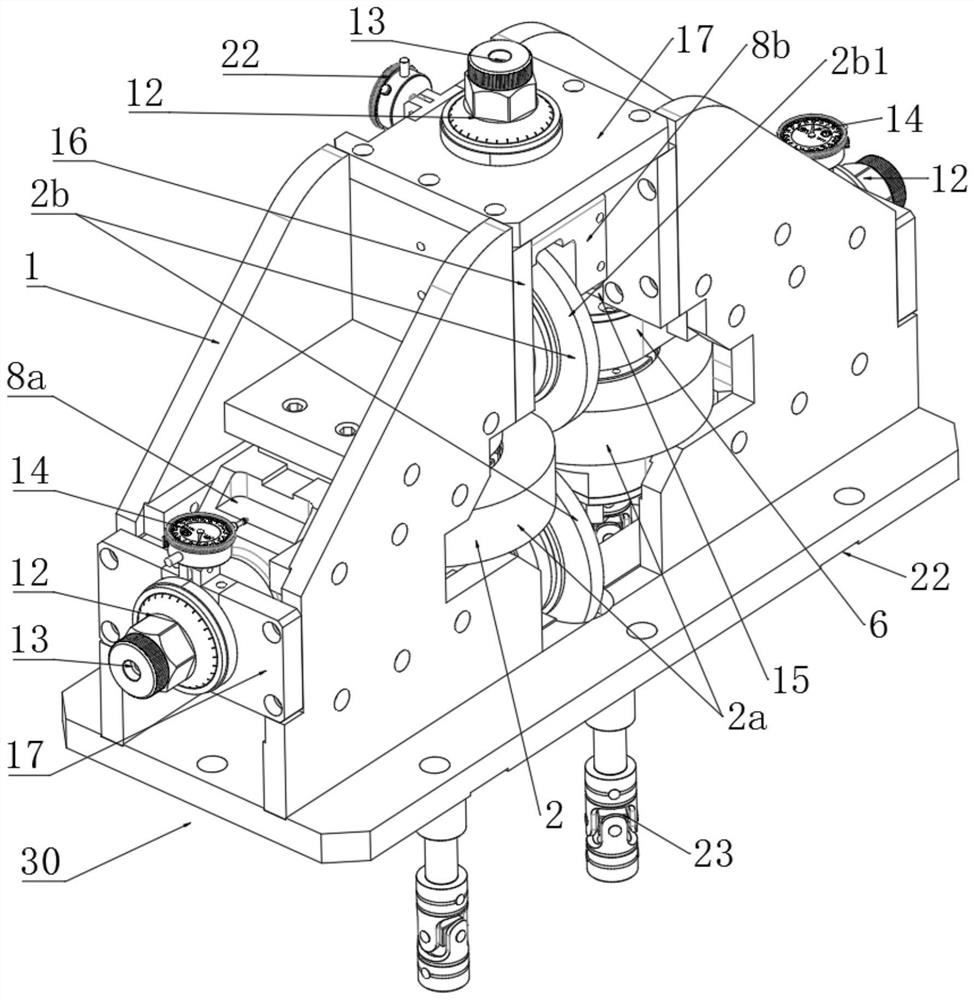

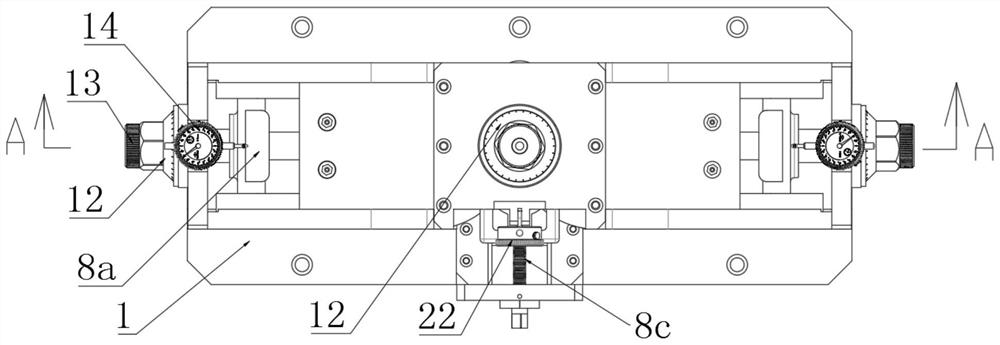

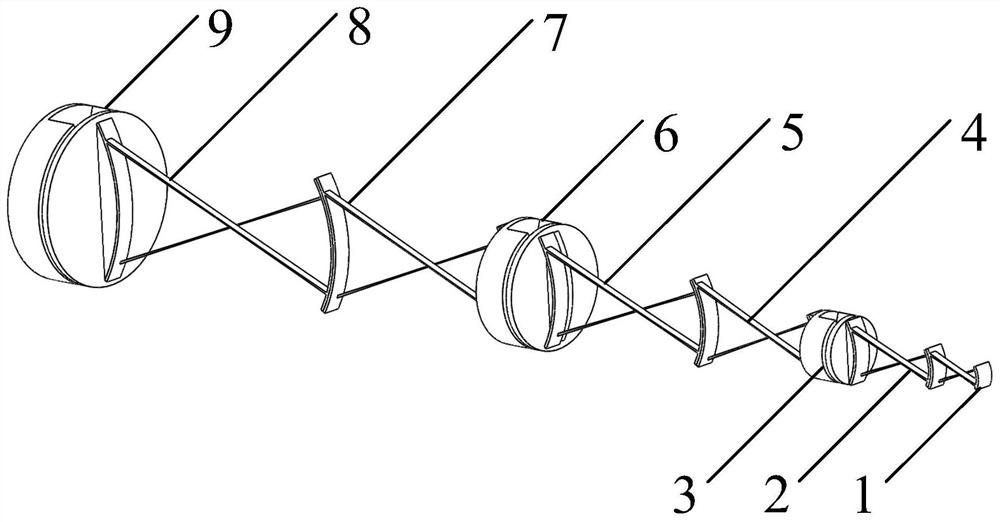

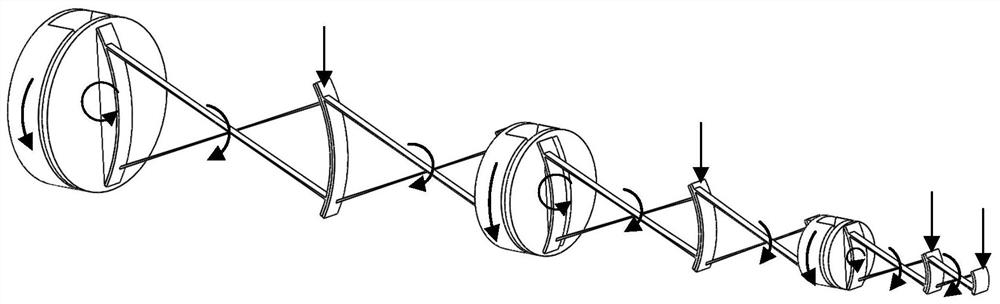

High-quality remodeling processing and manufacturing system for superconducting conductor

PendingCN113470888AHigh deformation accuracyHigh precisionSuperconductors/hyperconductorsSuperconductor devicesElectrical conductorEngineering

The invention discloses a high-quality modification processing and manufacturing system for a superconducting conductor. The high-quality modification processing and manufacturing system comprises an extrusion deformation device, the extrusion deformation device comprises a plurality of rolling deformation modules, the rolling deformation modules are sequentially distributed on corresponding racks in the length direction of a superconducting conductor, and each rolling deformation module comprises a mold frame and model pressing wheels which correspond to the periphery of the corresponding superconducting conductor and are arranged on the mold frame. According to the system, a superconducting conductor can be subjected to deformation modification and / or diameter shrinkage, for example, a circular tube superconducting conductor is subjected to modification processing to be made into a square shape and the like. The high-quality modification processing and manufacturing system is simple and reasonable in structure, high in machining and manufacturing precision, high in efficiency and low in machining and manufacturing cost.

Owner:宜春市龙腾机械电气有限公司

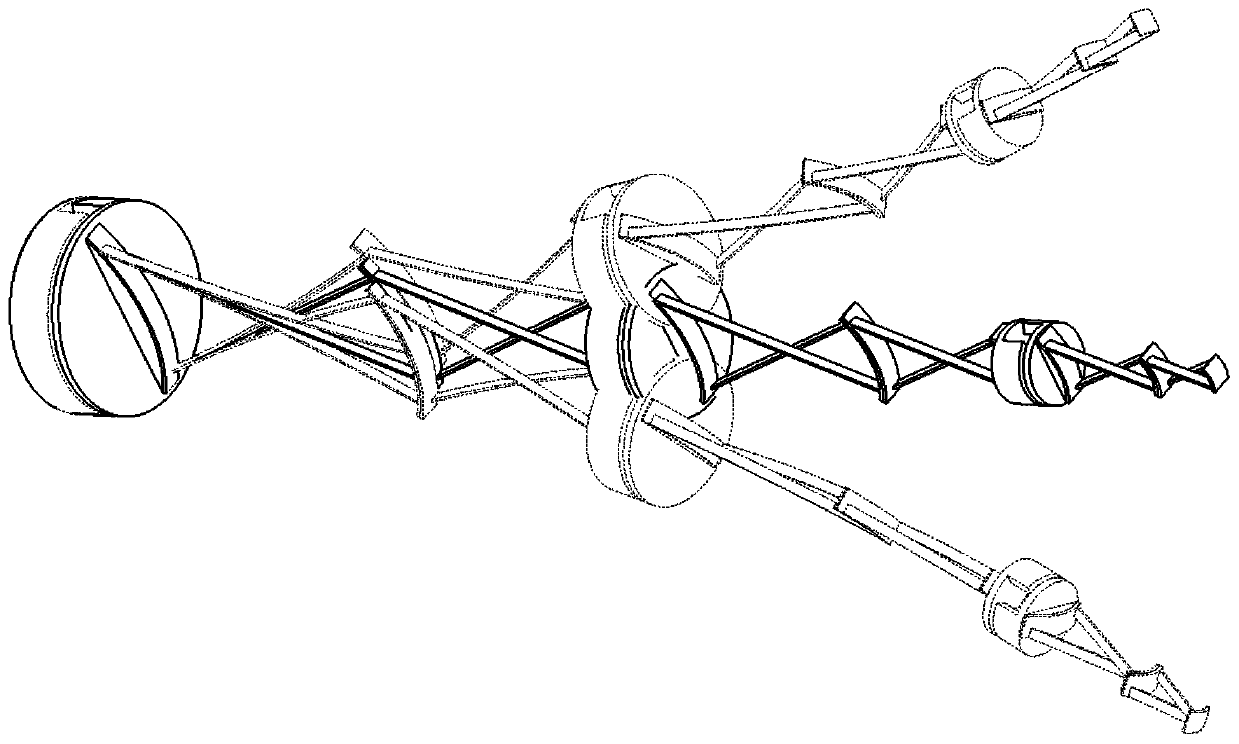

Passive bending axial rotation mechanism based on arc surface free end and three reed cross reeds

ActiveCN110550171BReduce offsetHigh deformation accuracyPropulsive elements of non-rotary typeEngineeringMechanical engineering

The invention relates to a passive bending axial rotation mechanism based on cambered surface free ends and three-reed crossed reeds. The whole multi-stage passive bending and axial rotation mechanismconsists of a plurality of crossed reed units with different sizes and varieties; and the structure of single crossed reed consists of two cambered surface free ends and the crossed reeds connected with the cambered surface free ends. Three reeds, the angle between two of which is 120 degrees, are crossed to form each crossed reed in charge of axial rotation deformation; the two ends of the reedare connected with the free ends; and when forming the passive bending and axial rotation mechanism, the reed units are connected by the corresponding free ends to form the multi-stage crossed reed structure. The passive bending axial rotation mechanism has the advantages of high precision, no friction, no hysteresis, no abrasion, no stiction, free of lubrication and the like, and can replace manysimilar passive deformation structures in the practical engineering application aspect.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

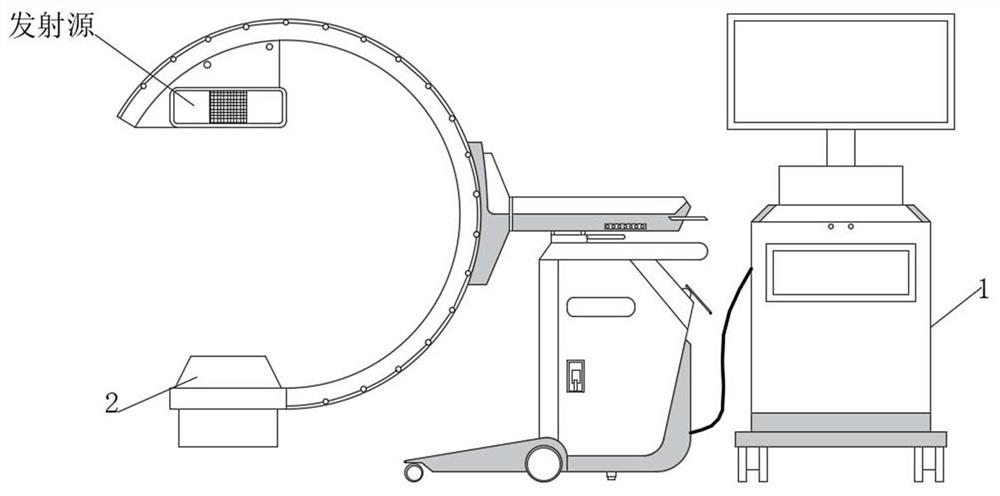

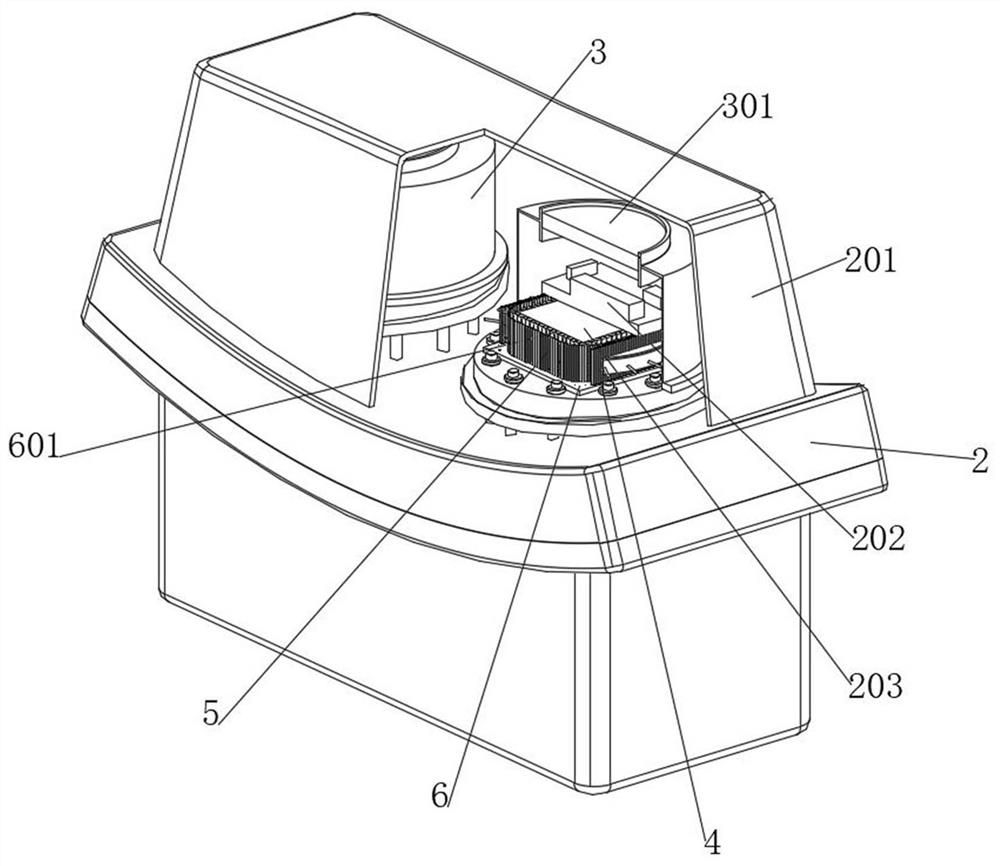

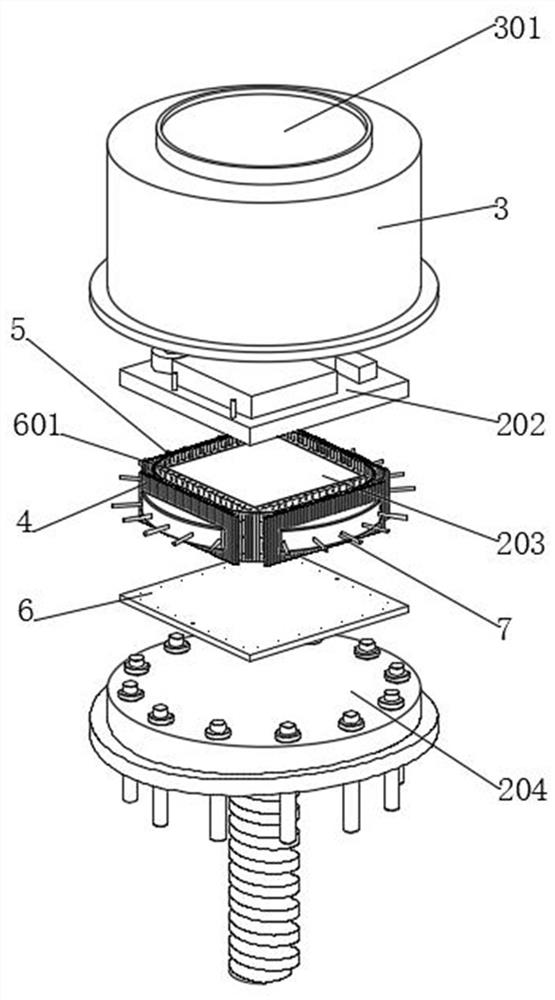

A c-arm ct device with high sensitivity

ActiveCN113520444BImprove cooling effectReduce distractionsComputerised tomographsTomographyImaging qualityNuclear medicine

The invention discloses a high-sensitivity C-arm CT device, which belongs to the field of photoelectric imaging. A high-sensitivity C-arm CT device includes a CT detector assembly. The CT detector assembly includes a detector protective shell, which is flexible and telescopic. The outer end of the shielding ring is connected with a number of matching load-bearing buffer components. Through the cooperation of the load-bearing buffer component, flexible telescopic shielding ring and isolated push component, it can effectively block the interference of the X-ray receiving plate and assist The cooler promotes the heat dissipation of the X-ray receiving board, effectively reducing the degree of temperature interference to the X-ray receiving board, thereby improving the stability of the signal conversion of the X-ray receiving board, improving the sensitivity of the CT detector components, and effectively improving the C-arm CT equipment. The image quality of the main body can effectively reduce the energy of X-rays, reduce the damage caused by the C-arm CT equipment main body to the patient's body, and improve the safety of the C-arm CT equipment main body.

Owner:江苏一影医疗设备有限公司

A method and device for extracting the centerline of a tubular target

ActiveCN107330935BHigh precisionIncrease speedImage enhancementImage analysisMechanical engineeringComputer technology

The present invention is applicable to the field of computer technology, and provides a method and device for extracting the centerline of a tubular target. The method includes: performing preprocessing on the image to be extracted for the centerline of the tubular target to obtain a corresponding enhanced image, and obtaining a gradient vector of the enhanced image Flow field, according to the gradient vector flow field, obtain the deformation force parameters corresponding to the initial ridge line segment list and extract the tubular target ridge point in the enhanced image, generate the initial ridge line segment list, and establish a regularized open curve deformation model. When the deformation end condition is not reached According to the model, a ridge segment in the initial ridge segment list is deformed and processed to obtain the corresponding tubular target center segment, and the initial ridge segment list is updated according to the ridge segments traversed during the deformation process. When the deformation end condition is reached, according to the tubular target The center line segment generates the center line of the tubular target, thereby optimizing the deformation process of the ridge line segment, reducing the deformation time of the ridge line segment, and improving the accuracy and extraction rate of the center line.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

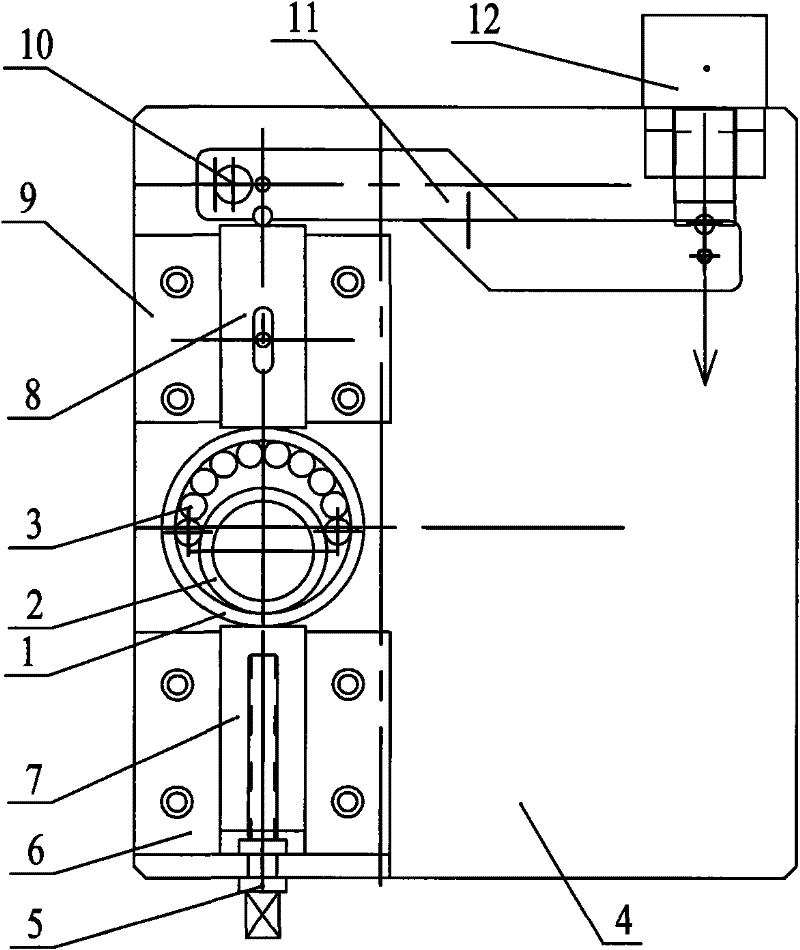

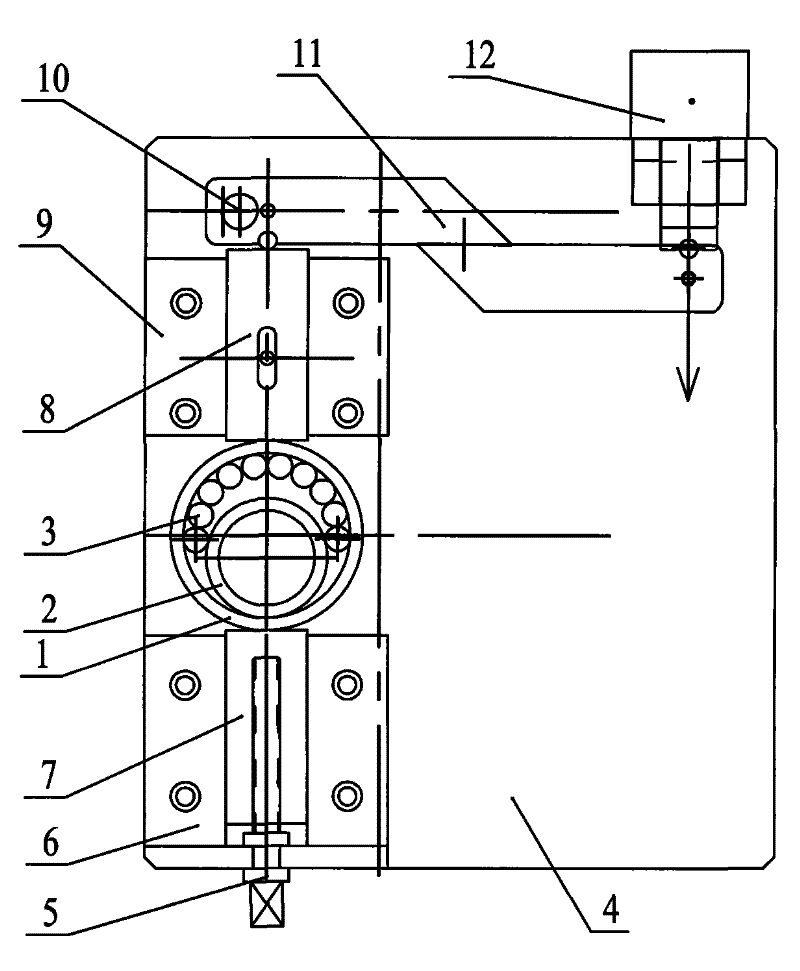

Bearing deformation assembling workpiece

InactiveCN101876348BReduce damage rateReduce manufacturing costBearing componentsEngineeringMechanical engineering

Owner:WUXI NO 2 BEARING

A high exhaust type die-casting mold for an integrated lamp housing

The invention discloses a high-exhaust type die-casting mold for an integrated lamp housing, which belongs to the field of die-casting molds. A temperature-variable exhaust cavity and an air cavity matched with the temperature-variable exhaust cavity are fixedly installed on the lamp housing die-casting mold body. The trough-type core is matched with the submerged air groove through the temperature-changing honeycomb composite bag. The temperature-changing honeycomb composite bag can absorb the airflow flowing in the submerged air groove, effectively improving the submerged air groove of the branch. The exhaust speed of the air groove can be improved, and the air in the die-casting gap can be pulled to reduce the residual air in the die-casting gap, so that the die-casting gap can quickly form a vacuum state, and the flow rate of the aluminum alloy metal liquid can be increased. While shortening the die-casting cycle, it can also effectively reduce the influence of air on the aluminum alloy metal liquid, improve the uniformity of the flow of aluminum alloy metal liquid, reduce the occurrence of air holes and shrinkage ribs on the die-casting integrated lamp housing, and effectively improve the quality of the die-casting integrated lamp. The molding quality of the shell.

Owner:南通科美自动化科技有限公司

Passive bending axial rotation mechanism based on cambered surface free ends and three-reed crossed reeds

ActiveCN110550171AHigh precisionFrictionlessPropulsive elements of non-rotary typeHysteresisStiction

The invention relates to a passive bending axial rotation mechanism based on cambered surface free ends and three-reed crossed reeds. The whole multi-stage passive bending and axial rotation mechanismconsists of a plurality of crossed reed units with different sizes and varieties; and the structure of single crossed reed consists of two cambered surface free ends and the crossed reeds connected with the cambered surface free ends. Three reeds, the angle between two of which is 120 degrees, are crossed to form each crossed reed in charge of axial rotation deformation; the two ends of the reedare connected with the free ends; and when forming the passive bending and axial rotation mechanism, the reed units are connected by the corresponding free ends to form the multi-stage crossed reed structure. The passive bending axial rotation mechanism has the advantages of high precision, no friction, no hysteresis, no abrasion, no stiction, free of lubrication and the like, and can replace manysimilar passive deformation structures in the practical engineering application aspect.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

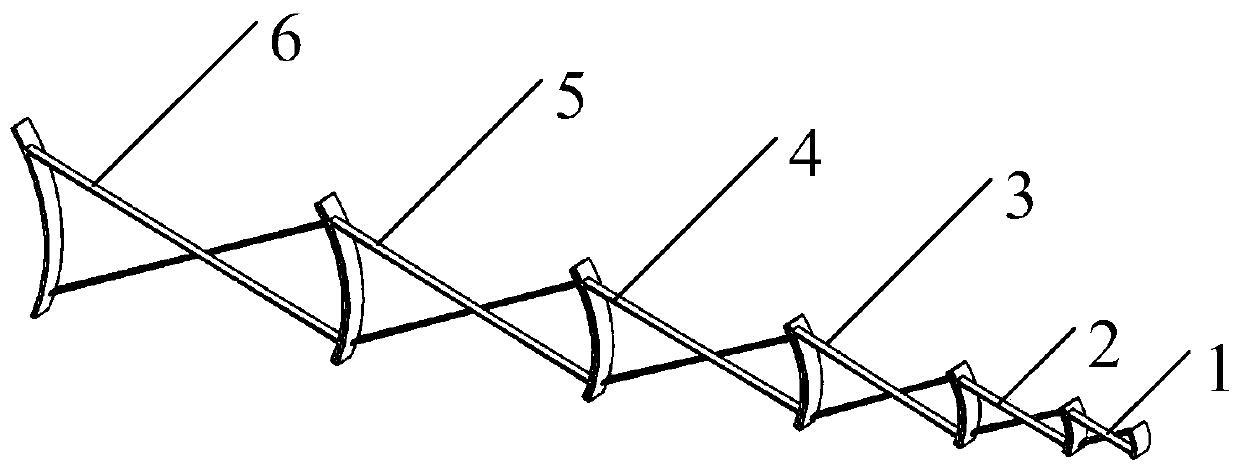

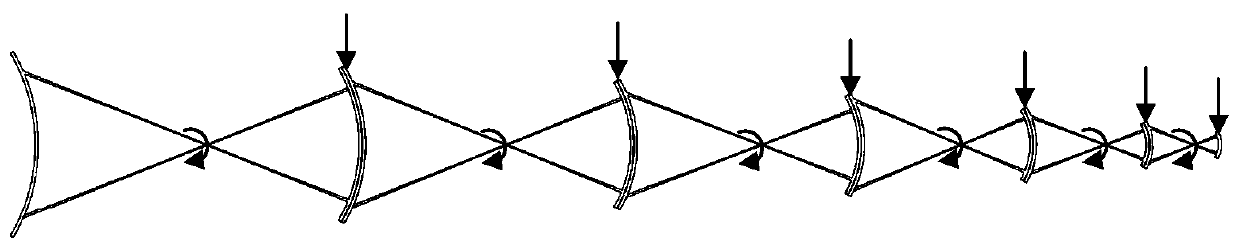

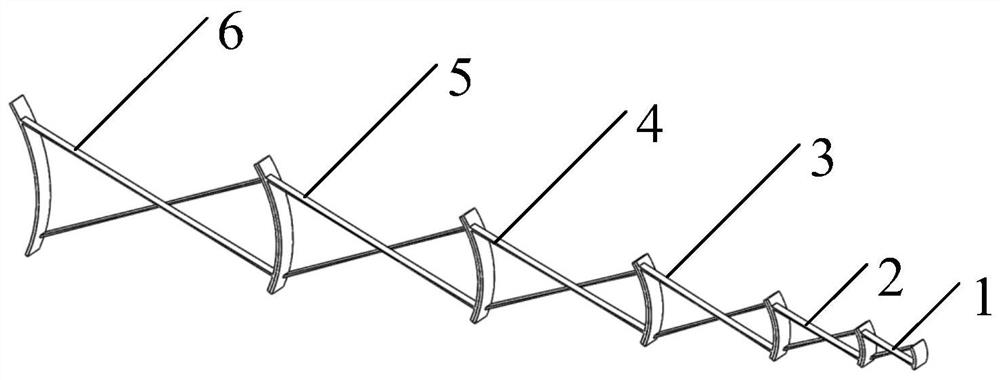

Multi-stage passive bending mechanism based on variable cross-section cross reeds

ActiveCN110434836AHigh precisionFrictionlessProgramme-controlled manipulatorPropulsive elements of non-rotary typeEngineeringMechanism based

The invention relates to a multi-stage passive bending mechanism based on variable cross-section cross reeds. The two equal-length variable cross-section reeds are symmetrically connected with two adjacent curved face free ends in a staggered manner in the length direction to form the first stage, and the cross section of each reed is thinnest at the crossed point and is thickest at the position connected with the corresponding free end. According to the curved face free ends in the scheme, the crossed points of the cross reeds and cross reed units are overlapped with respect to the circle center of the free end of the outer side of an entire bending mechanism, so that when each cross reed unit is passively bent and deformed, the offset of each intersection is reduced, and the deformationaccuracy is higher. The variable cross-section cross reed units are adopted, that is, the cross section of each reed is thinnest at the intersection and is thickest at the portion connected to the corresponding free end, so that greater passive deformation is achieved under the condition that deformation accuracy is ensured, and the deformation accuracy of the cross reed units in the scheme is higher under the same deformation degree.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Concrete temperature stress testing machine with separable mold and vibration

ActiveCN106248914BImprove pouring qualityHigh deformation accuracyPreparing sample for investigationMaterial testing goodsTemperature stressMeasurement device

The invention discloses a concrete temperature stress testing machine achieving mold separable vibrating. The testing machine comprises a main testing machine body, a concrete sample mold detachably connected with the main testing machine body, and a deformation measurement device. According to the concrete temperature stress testing machine achieving mold separable vibrating, mounting and demounting of the concrete sample mold and the main testing machine body are convenient, the concrete sample mold can be independently poured and vibrated after being demounted, the concrete sample mold is mounted on the main testing machine body for relevant temperature stress testing after the vibrating quality requirement is met, the pouring quality of concrete is greatly improved, and the credibility and comparability of the test result are better.

Owner:TSINGHUA UNIV +1

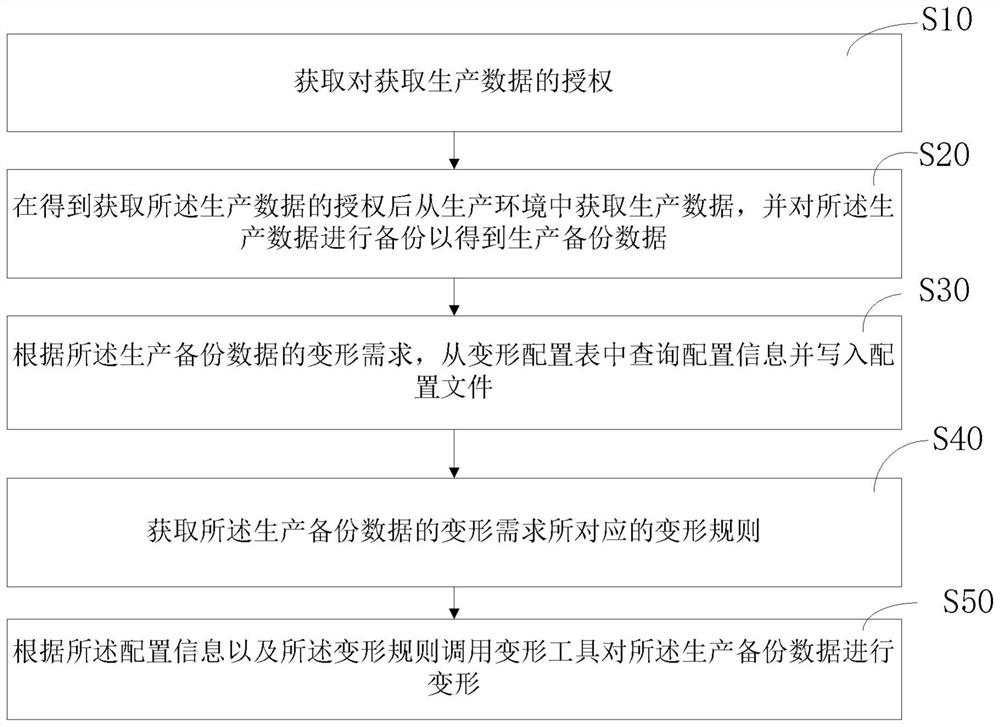

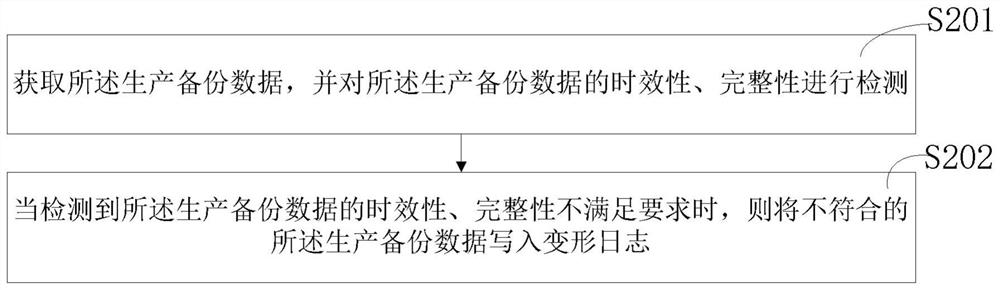

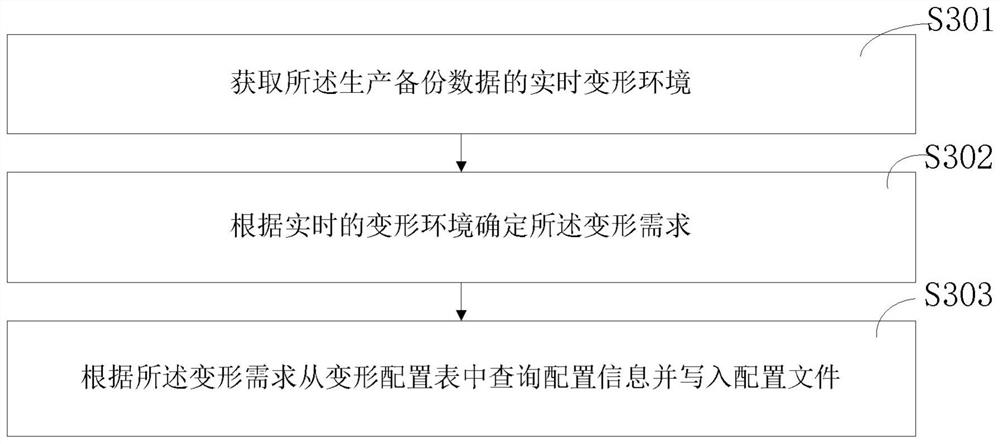

Database data deformation method, system, equipment, medium and product

PendingCN114546729AHigh degree of automationFully automatedRelational databasesRedundant operation error correctionData miningAuthorization

The invention provides a database data deformation method which can be applied to the field of financial systems and is mainly used for performing deformation processing on sensitive data in the financial systems. Comprising the following steps: acquiring authorization for acquiring production data; obtaining the production data from the production environment after the authorization of obtaining the production data is obtained, and backing up the production data to obtain production backup data; according to the deformation requirement of the production backup data, querying configuration information from the deformation configuration table and writing the configuration information into a configuration file; obtaining a deformation rule corresponding to the deformation demand of the production backup data; and calling a deformation tool to deform the production backup data according to the configuration information and the deformation rule. According to the technical scheme provided by the invention, the automation degree of deformation is effectively improved, through the uniform configuration file, adaptation is carried out for different environments and requirements, parallel execution of multiple sets of environments is realized, the human input is greatly reduced, and the deformation accuracy is improved.

Owner:INDUSTRIAL AND COMMERCIAL BANK OF CHINA

Automatic profile bending device, method for realizing three-dimensional bending by using device and application

ActiveCN111014391AAutomatic 3D bendingHigh deformation efficiencyMetal-working feeding devicesPositioning devicesDeformation effectEngineering

The invention provides an automatic profile bending device, a method for realizing three-dimensional bending by using the device and an application. Two motion mechanisms for two-dimensional translational motion and rotating motion in two drive planes are adopted, a certain included angle is formed by the two motion mechanisms, different positions of the two clamping mechanisms clamping a materialare combined, the relative deformation movement of the clamping positions is achieved under the driving of the two motion mechanisms, the required material three-dimensional bending is achieved by changing the clamping positions, the automatic profile bending device, the method for realizing the three-dimensional bending by using the device and the application have the advantages that the deformation efficiency is high, the deformation precision is high, the repeated operation can be achieved, the deformation effect are consistent, and the like, and can be applied to the technical field of medical bone repair and the like.

Owner:CIXI INST OF BIOMEDICAL ENG NINGBO INST OF MATERIALS TECH & ENG CHINESE ACAD OF SCI +2

A Passive Bending Axial Rotation Mechanism Based on Variable Cross-section Cross Springs

ActiveCN110525620BReduce offsetHigh deformation accuracyPropulsive elements of non-rotary typeEngineeringMechanical engineering

The invention relates to a passive bending axial rotation mechanism based on variable cross-section cross reeds. The entire multi-stage passive bending and axial rotation mechanism is composed of a plurality of cross reed units of different sizes and types. For the units that undertake passive bending , the free end of the arc surface is used, and the cross point of the cross reed overlaps with the center of the circle of the cross reed unit relative to the outer free end of the entire bending mechanism, which makes the offset of the cross point of each cross reed unit during passive bending deformation has decreased, making its deformation more accurate. The cross reed adopts a cross reed unit with variable cross section. The cross section of each reed is the thinnest at the intersection point and the thickest at the part connected to the free end, which enables greater passive deformation while ensuring deformation accuracy. The invention has the advantages of high precision, no friction, no hysteresis, no wear, no static resistance, no lubrication and so on.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

A magnetostrictive shrapnel-type microgripper driven by galfenol flakes

ActiveCN105119518BIncrease stiffnessLarge clamping forceMicromanipulatorPiezoelectric/electrostriction/magnetostriction machinesEngineeringGalfenol

The invention discloses a magnetostrictive shrapnel type micro-clamp driven by a Galfenol sheet, which comprises a pliers body, one end of the pliers body is closed, the other end is open, and a coil is wound outside the pliers body; The shrapnel is arranged oppositely, one end of the shrapnel is connected with the closed end face of the caliper body, and the other end of the shrapnel extends out of the opening end of the pliers body; two supporting pieces perpendicular to the shrapnel are arranged at the opening end of the pliers body, and one end of the supporting piece is connected to the shrapnel. The outer surface of the pliers is connected, and the other end of the support piece is connected with the inner wall of the caliper body; the Galfenol sheet is pasted on the outer surface of the shrapnel located inside the pliers body, and the maximum magnetostrictive direction of the Galfenol sheet is consistent with the length direction of the shrapnel. The invention utilizes the deformation of the Galfenol sheet in the magnetic field to drive the bending deformation of the shrapnel to realize clamping, the clamping range is large, the deformation precision is high, the driving voltage is low, and the reliability is good.

Owner:NANCHANG INST OF TECH

A Multistage Passive Bending Mechanism Based on Variable Cross-section Cross Reeds

ActiveCN110434836BHigh precisionFrictionlessProgramme-controlled manipulatorPropulsive elements of non-rotary typeEngineeringMechanical engineering

The invention relates to a multi-stage passive bending mechanism based on cross-section reeds with variable cross-sections. Two reeds with variable cross-sections of equal length are symmetrically cross-connected along the length direction of two adjacent arc-surface free ends to form one stage. The cross-section of a reed is thinnest at the intersection and thickest at the point where it joins the free end. In the free end of the arc surface of this scheme, the intersection point of the cross reed and the unit of the cross reed overlap with the center of the outer free end of the entire bending mechanism, so that the offset of the intersection point of each cross reed unit during passive bending deformation is The lower the deformation, the higher the deformation accuracy. The cross-section reed unit with variable cross-section is adopted, that is, the section of each reed is the thinnest at the intersection and the thickest at the part connected to the free end, which enables a large passive deformation to be achieved while ensuring the deformation accuracy, and at the same Under the deformation degree of , the deformation accuracy of the cross-reed unit described in this scheme is higher.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

An anti-theft lock device

InactiveCN105775019BGreat driving forceLarge deformationAnti-theft cycle devicesCycle brakesTransformerShape-memory alloy

The invention discloses an anti-theft lock device, which comprises a circular support frame and a power supply. A pair of beams are symmetrically arranged at the front and rear ends of the circular support frame, that is, an upper beam and a lower beam. A pair of brake pads are elastically connected between them. The brake pads are divided into upper brake pads and lower brake pads. A set of shape-memory alloy springs are arranged between the corresponding sides of the upper brake pads and the lower brake pads. Each set of shape-memory alloy springs The alloy springs all include a one-way heat-shrinkable spring and a double-way heat-extensible and cold-shrinkable spring, and the two ends of the one-way heat-shrinkable spring and the two ends of the double-way heat-extensible and cold-shrinkable spring are respectively connected to the power supply through a brake switch and a transformer. The invention controls the input current signal to drive the shape-memory alloy spring so that the brake pad hugs the rotating disc, so as to achieve the purpose of locking the wheel. The device has a relatively simple structure, is easy to install, has low cost, and is beneficial to market promotion.

Owner:NANCHANG INST OF TECH

Profile automatic bending device, method and application of using it to realize three-dimensional bending

ActiveCN111014391BAutomatic 3D bendingHigh deformation efficiencyMetal-working feeding devicesPositioning devicesDeformation effectClassical mechanics

The invention provides an automatic profile bending device, a method for realizing three-dimensional bending by using the device, and an application thereof. Two motion mechanisms that can drive two-dimensional translational motion and rotation motion in the plane are adopted, and the two motion mechanisms form a certain angle, combined with the different positions of the materials clamped by the two clamping mechanisms, it is realized under the drive of the two motion mechanisms The relative deformation movement of the clamped position realizes the required three-dimensional bending of the material by changing the clamping position. It has the advantages of high deformation efficiency, high deformation accuracy, repeatable operation and consistent deformation effect. It can be applied to medical bone repair and other technologies field.

Owner:CIXI INST OF BIOMEDICAL ENG NINGBO INST OF MATERIALS TECH & ENG CHINESE ACAD OF SCI +2

A Multistage Passive Bending Mechanism Based on the Crossed Reeds at the Free Ends of the Curved Surface

ActiveCN110480618BReduce offsetHigh deformation accuracyProgramme-controlled manipulatorPropulsive elements of non-rotary typeClassical mechanicsStructural engineering

The invention relates to a multi-stage passive bending mechanism based on crossed reeds at free ends of cambered surfaces, comprising a plurality of free ends of cambered surfaces and crossed reeds; The adjacent free ends of the arc surface form a first stage, and the bending stiffness of each stage depends on the material, thickness of the reed, the angle between the two reeds and the position of their intersection; in the cross-reed bending mechanism based on conventional parallel free ends , the arc free end used in this scheme, and the intersection point of the cross reed and the center of the cross reed unit relative to the center of the outer free end of the entire bending mechanism, which makes the intersection of each cross reed unit passive bending deformation. The offset has been reduced, making its deformation more accurate. When the free end is subjected to external force, it is better to deform along its force direction.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com