A high exhaust type die-casting mold for an integrated lamp housing

A die-casting mold and exhaust type technology, which is applied in the field of high-exhaust die-casting molds for integrated lamp housings. Die-casting cycle and other issues, to achieve the effect of shortening the die-casting cycle, shortening the molding time, shortening the flow time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment 1 will clearly and completely describe the technical solution in conjunction with the disclosed drawings, so as to make the purpose, technical solution and beneficial effects of the disclosed embodiment more clear. Apparently, the described embodiments are some of the embodiments of the present disclosure, not all of them. Based on the described embodiments of the present disclosure, all other embodiments obtained by persons of ordinary skill in the art without creative effort fall within the protection scope of the present disclosure.

[0033] Unless otherwise defined, the technical terms or scientific terms used in the present disclosure shall have the conventional meanings understood by those skilled in the present disclosure. "First", "second" and similar words used in the present disclosure do not indicate any order, quantity or importance, but are only used to distinguish different components. "Comprising" and similar words mean that the elements ...

Embodiment 1

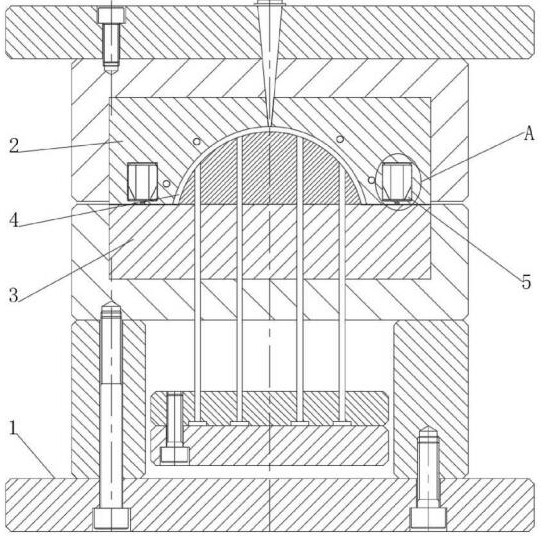

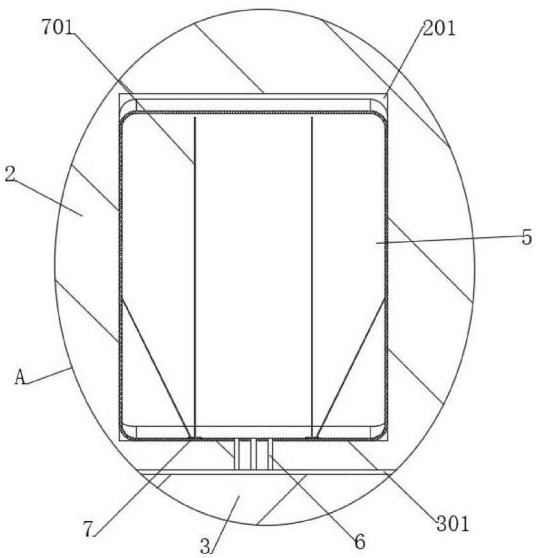

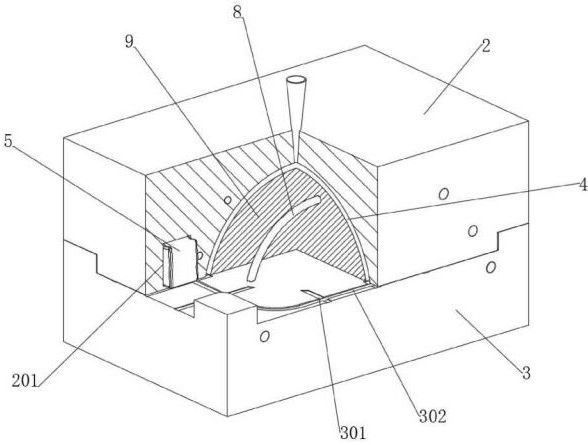

[0035]Please refer to Figure 1-10, including the lamp housing die-casting mold body 1, the temperature-varying exhaust cavity 2 and the air-groove core 3 matched with the temperature-varying exhaust cavity 2 are fixedly installed on the lamp housing die-casting mold body 1 , and the die-casting molding gap 4 corresponding to the die-casting integrated lamp housing 11 is formed between the temperature-varying exhaust cavity 2 and the air-groove core 3, please refer to Figure 3, the upper end of the air-groove core 3 is provided with multiple The die-casting gap 4 is connected to the branch sunken air groove 301, and the upper end of the air groove type core 3 is provided with an annular flow equalizing air groove 302, which is connected with the branch sunken air groove 301, And the depth of the annular flow equalizing groove 302 is 0.4-0.6 times of the depth of the submerged air groove 301 of the branch. Through the annular flow equalizing groove 302, the plurality of submerged...

Embodiment 2

[0039] Please refer to Figure 1-10, the upper end of the lamp housing die-casting mold body 1 is fixedly connected with a sprue bushing 101, and the lower end of the sprue bushing 101 extends to the inside of the temperature-varying exhaust cavity 2 and matches with the die-casting gap 4. Please refer to Figure 8, there are multiple direct-cooling cavity waterways 202 in the temperature-variable exhaust cavity 2 that match the die-casting gap 4, and the direct-cooling cavity waterways 202 are located between the temperature-variable exhaust auxiliary cavity 201 and Between die-casting gaps 4. Please refer to Figure 8, the upper end of the air groove type core 3 is fixedly connected with the lamp housing core insert 9 by bolts, and a pair of arch bridge-shaped core waterways 8 are arranged in the air groove type core 3, and the arch bridge shape core waterways 8 and The lamp housing core insert 9 matches. During die-casting, the aluminum alloy metal liquid enters the die-casti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com