K-band radar-based track non-contact deformation high-precision measurement method

A non-contact, measuring method technology, applied in the direction of radio wave measurement system, railway vehicle shape measuring device, measuring device, etc., can solve the problems of insufficient measurement accuracy, increased monitoring complexity and implementation difficulty, and inability to quickly distinguish rails, etc. , to achieve the effects of small amount of calculation, improved deformation accuracy, and simple implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

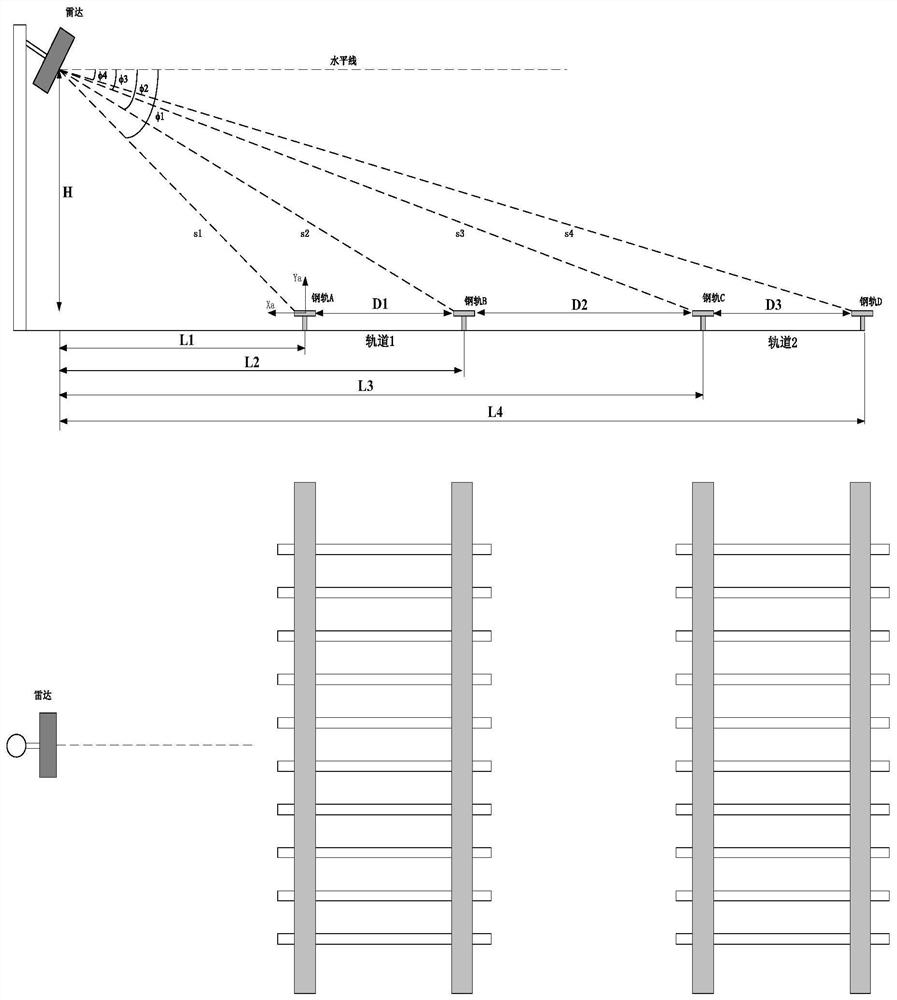

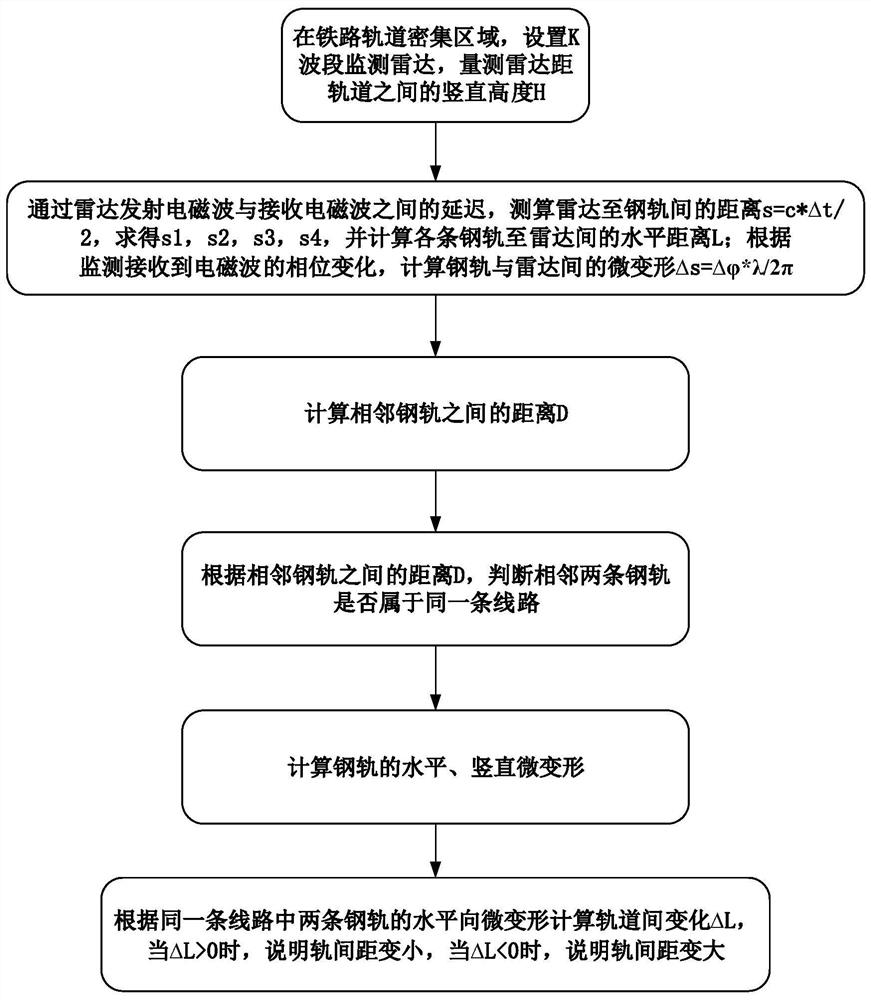

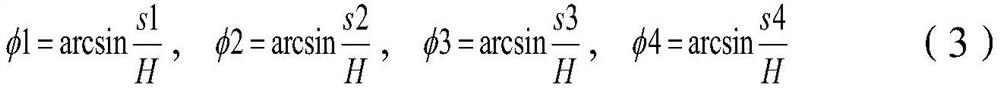

[0037] The present invention will be clearly and completely described below in conjunction with the accompanying drawings and embodiments, and the technical problems and beneficial effects solved by the technical solutions of the present invention are also described. It should be pointed out that the described embodiments are only intended to facilitate the implementation of the present invention understood without any limitation.

[0038] Consider that the K-band radar in the prior art has the following advantages with respect to radars of other bands (such as X-band):

[0039] (1) From the comparison of lobe width, the positioning accuracy of Ku-band radar is higher than that of X-band radar;

[0040] (2) Since the operating frequency of Ku-band radar is 15.7GHz-16.7GHz, which is much higher than that of X-band radar at 9.0GHz-9.5GHz, Ku-band radar is less susceptible to interference than X-band radar. Still have good effect under;

[0041] (3) Since the vertical beam depr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com