Concrete temperature stress testing machine achieving mold separable vibrating

A concrete temperature and stress test technology, which is applied in the direction of analyzing materials, material inspection products, and preparation of test samples, can solve problems such as poor vibration quality, large natural differences between test results, etc., and achieve reliability and reliability. Good analogy, convenient installation and disassembly, and the effect of improving pouring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

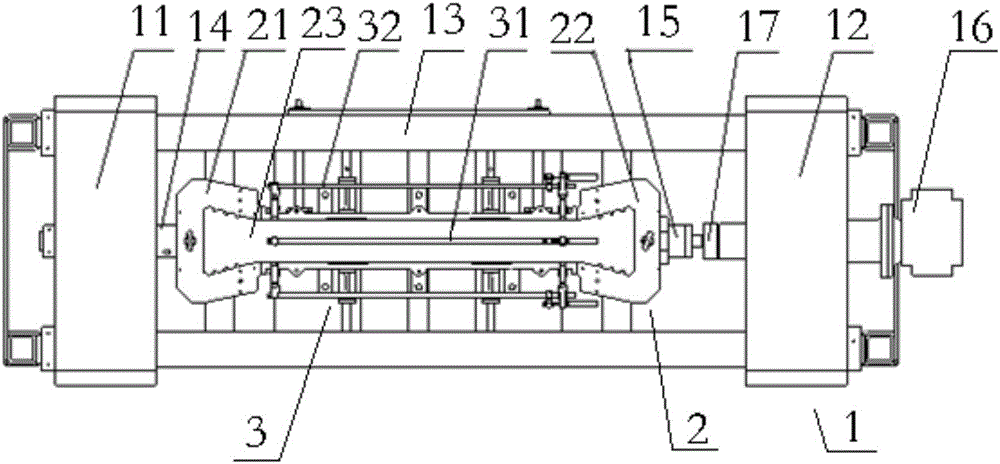

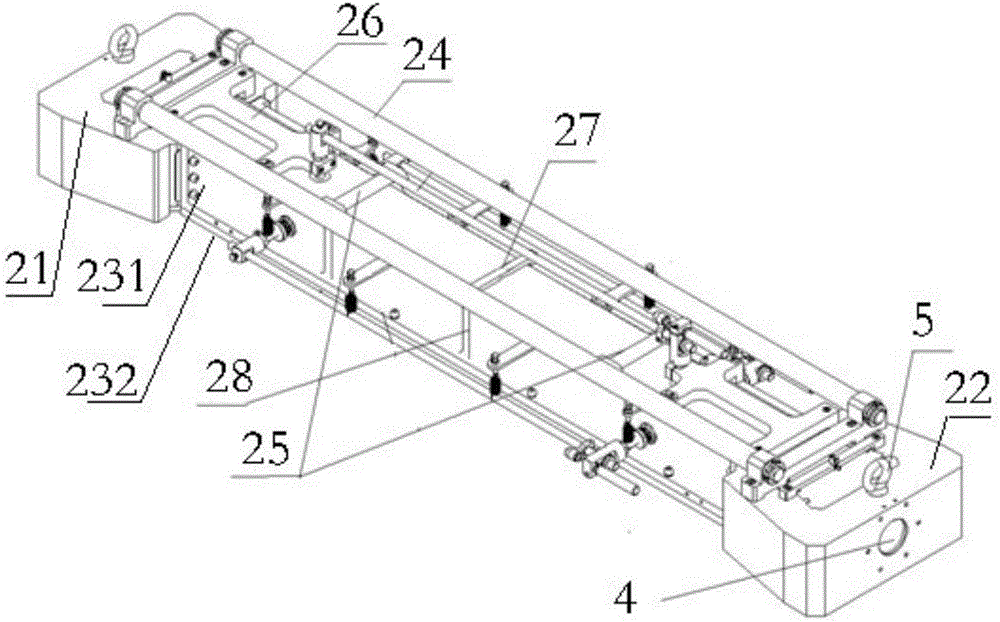

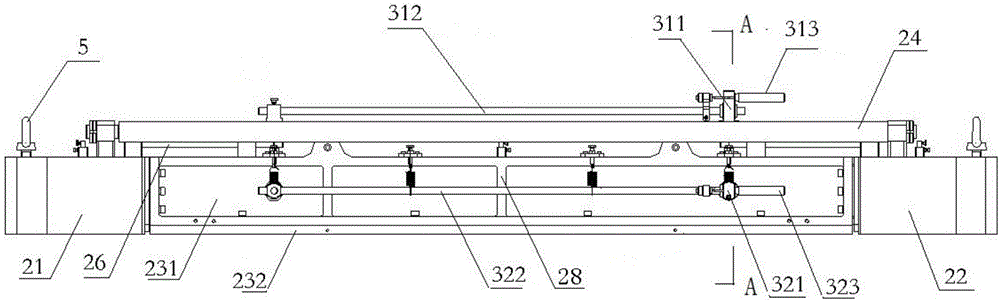

[0025] see figure 1 , a concrete temperature stress testing machine with detachable mold and vibration provided by an embodiment of the present invention includes a main machine 1 of the testing machine, a concrete specimen mold 2 and a deformation measuring device 3 . Wherein, the testing machine host 1 includes a fixed chuck side fixed end 11, a movable chuck side fixed end 12, and a pair of light rods 13 that are fixedly connected to the fixed chuck side fixed end 11 and the movable chuck side fixed end 12. The inner side of the fixed end 11 on the chuck side is connected to the fixed end universal joint 14 by bolts, the inner side of the fixed end 12 on the movable chuck side is connected to the movable end universal joint 15 by bolts, and the outer side of the fixed end 12 on the movable chuck side is connected to a servo motor 16. The servo motor 16 is connected to the load sensor 17 through bolts, and the load sensor 17 is connected to the movable end universal joint 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com