Multi-point-contact flexible bearing for harmonic reducer

A harmonic reducer and flexible bearing technology, applied in rolling contact bearings, transmission parts, belts/chains/gears, etc., can solve problems such as large contact force, insufficient ball restraint, distortion and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

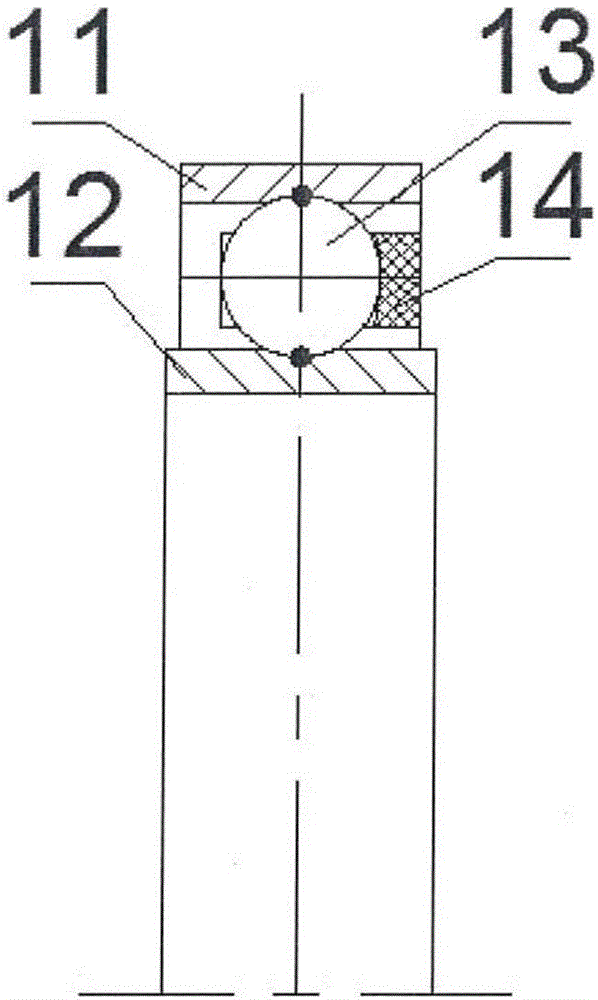

[0046] Embodiment 1, as Figure 5A Three point contact flexible ball bearing shown

[0047] Figure 5A Among them, 51A is the outer ring of the bearing, 52A is the inner ring, 53A is the ball, 54A is the cage, and the 53A ball is embedded in the raceway of the outer ring shown in 51A and the inner ring shown in 52A and is held by the cage shown in 54A spaced along the circumference. The outer ring 51A is a peach-shaped channel composed of two semicircular arcs, and the centers of the two semicircular arcs are respectively O e1 , O e2 , the center of the ball 53A is O, the ball 53A has two contact points with the channel of the outer ring 51A, and the contact point is not at the bottom of the channel, forming a contact angle α; the inner ring 52A is a single arc channel, and the center is O i , the ball 53A has a single contact point with the channel of the inner ring 52A, the contact point is at the bottom of the channel, the contact angle is 0, and the ball 53A has three ...

Embodiment 2

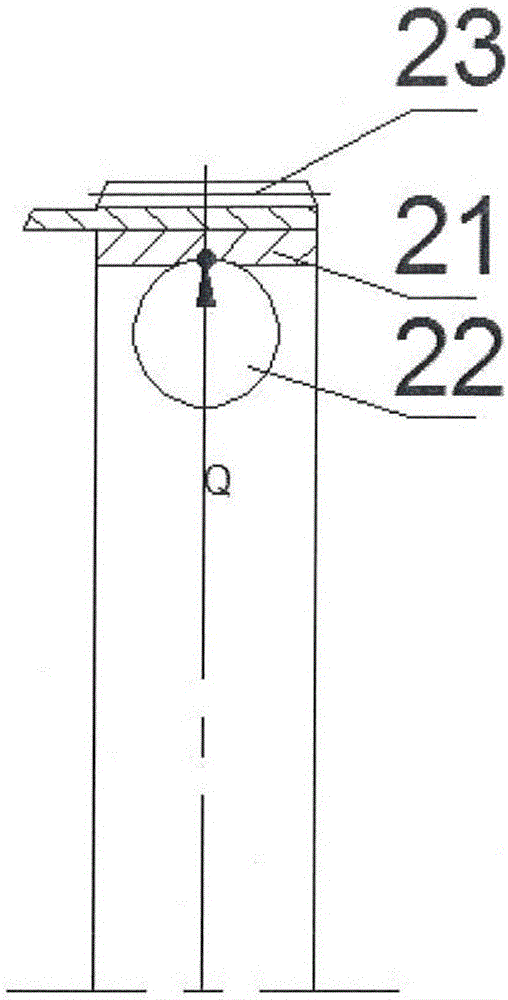

[0050] Embodiment 2, as Figure 5B Four point contact flexible ball bearing shown

[0051] Figure 5B Among them, 51B is the bearing outer ring, 52B is the inner ring, 53B is the ball, 54B is the cage, and the 53B ball is embedded in the raceway of the outer ring shown in 51B and the inner ring shown in 52B and is held by the cage shown in 54B spaced along the circumference. The outer ring 51B is an elliptical arc channel, and the center of the ellipse where the elliptical arc is located is O e , the curvature of each point on the channel changes with the position, the center of the ball 53B is O, and there are two contact points with the channel of the outer ring 51B, the contact points are not at the bottom of the channel, forming a contact angle α e ; The inner ring 52B is also an elliptical arc channel, and the center of the ellipse where the elliptical arc is located is O i , the curvature of each point on the channel changes with the position, the ball 53B has two co...

Embodiment 3

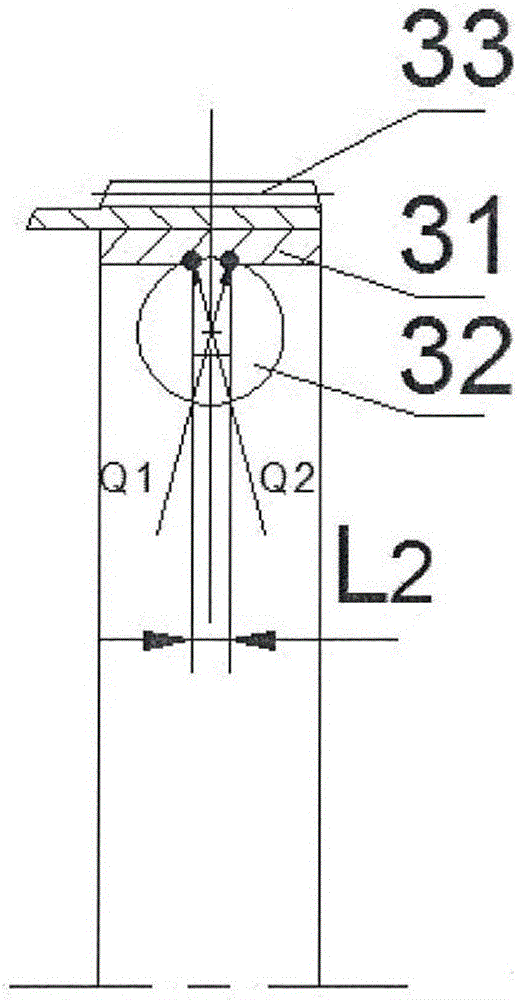

[0055] Embodiment 3, as Figure 6A The shown rollers are in line type raceway infinite point contact inner ring ribless flexible roller bearing

[0056] Figure 6AAmong them, 61A is an outer ring, 62A is an inner ring, 63A is a roller inserted between the outer ring raceway and the inner ring raceway, and 64A is a cage that separates each ball 63A along the bearing circumferential direction. The outer ring 61A has double ribs, the inner ring 62A has no ribs, the outer ring 61A raceway, the inner ring 62A raceway and the generatrix of the roller 63A are all straight lines, and the roller 63A is the same as the outer ring 61A raceway and the inner ring 62A The raceway is in contact with the entire length of the roller 63A, and there are infinite contact points. In this flexible bearing, since the inner ring 62A has no rib, the inner ring 62A is a separable inner ring.

[0057] The outer ring 61A and the inner ring 62A of the flexible roller bearing are made of bearing steel, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com