Deformation-controllable four-dimension (4D) printing method for composite material embedded with continuous fiber

A composite material and continuous fiber technology, applied in additive processing, 3D object support structure, additive manufacturing, etc., can solve the problems of discontinuous deformation process, poor design, no continuous fiber composite material 4D printing method, etc., and achieve high reliability The effect of controllability and high deformation precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings.

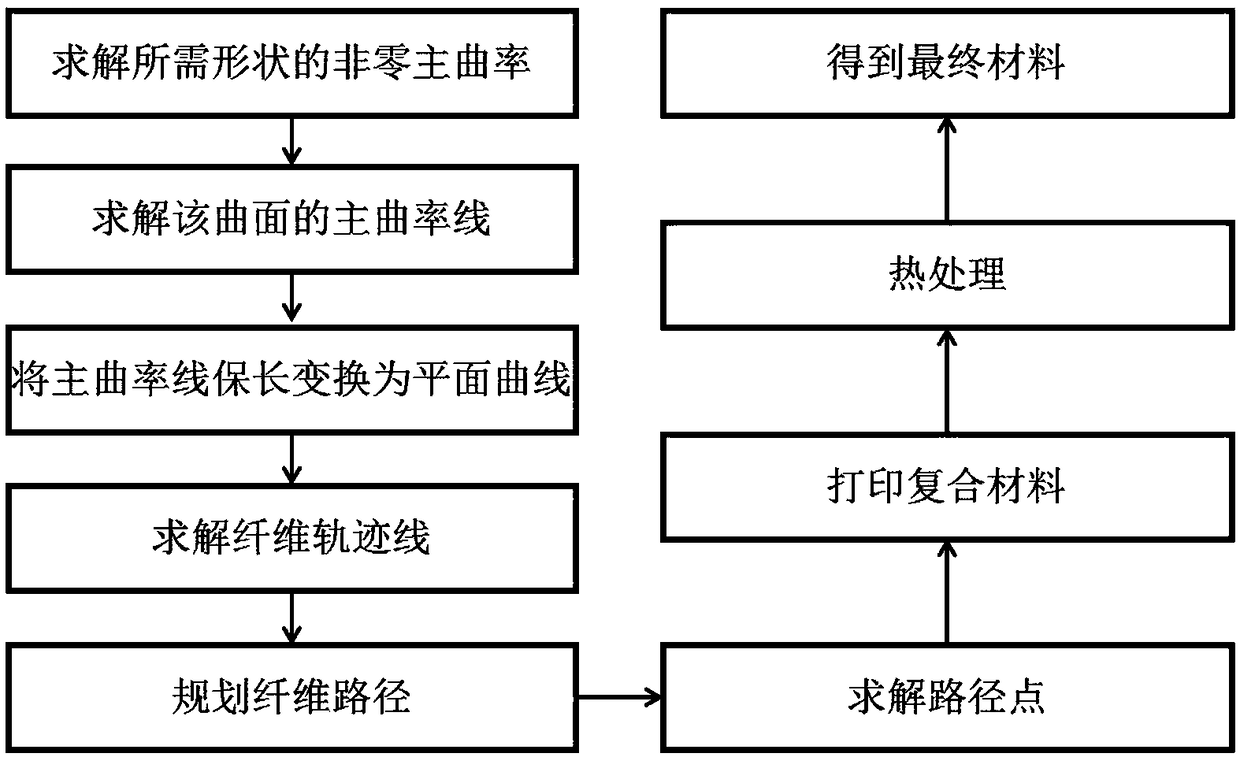

[0028] refer to figure 1 , a 4D printing method for controllable deformation of continuous fibers embedded in composite materials, comprising the following steps:

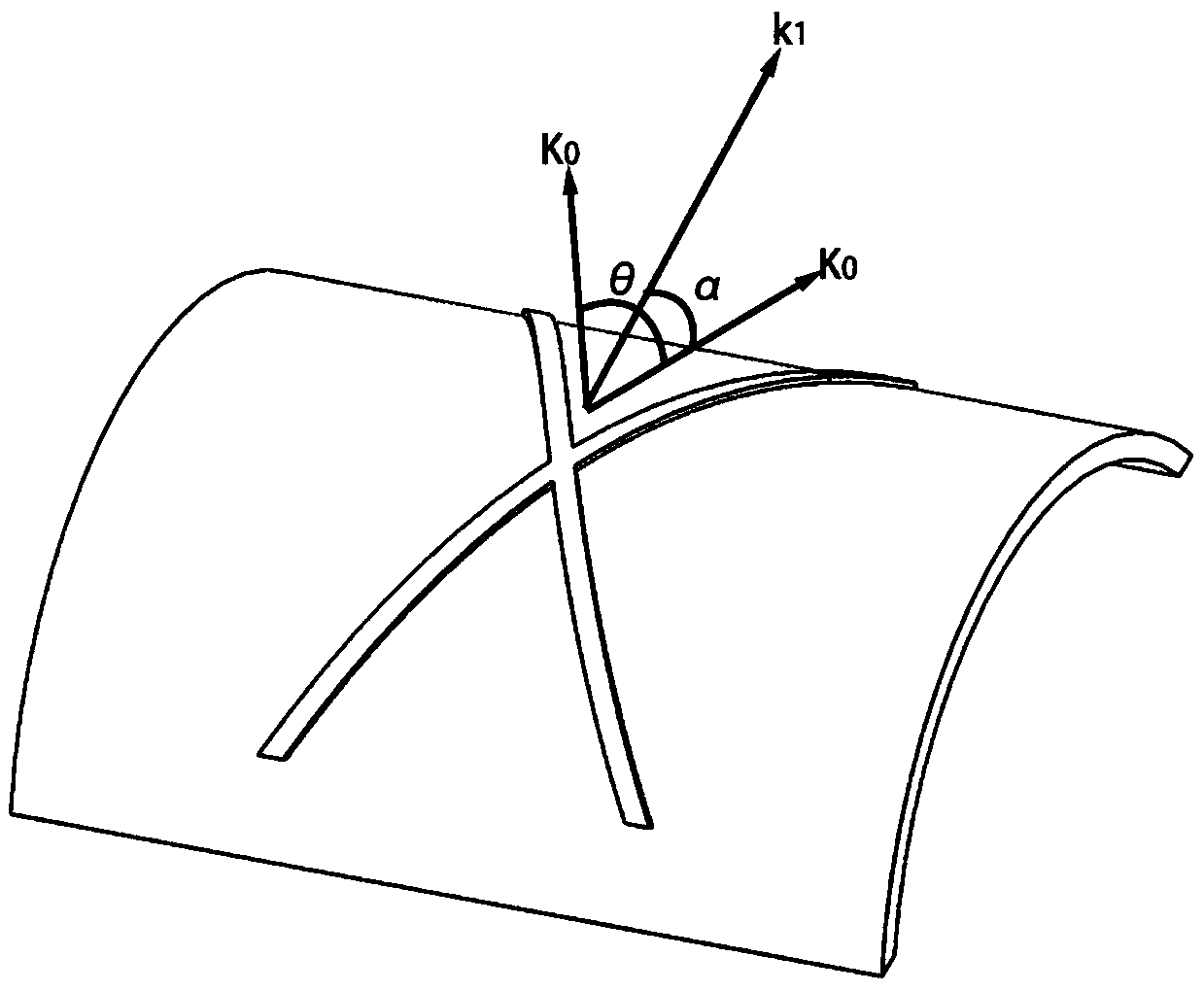

[0029] 1) Solve the non-zero principal curvature of the desired shape: every point on the developable surface has a principal curvature equal to zero and a non-zero principal curvature. For any cylinder r=(f(u),g(u), v), its non-zero principal curvature magnitude:

[0030]

[0031] Principal directions of nonzero principal curvature:

[0032]

[0033] For any conical surface r=(vf(u),vg(u),v), its non-zero principal curvature size:

[0034]

[0035] Principal directions of nonzero principal curvature:

[0036]

[0037] 2) Solve the principal curvature line of the surface: for any cylindrical surface, solve the differential equation (5) to obtain its non-zero principal curvature lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com