High-quality remodeling processing and manufacturing system for superconducting conductor

A technology of superconducting conductors and production systems, applied in superconducting/high-conducting conductors, usage of superconducting elements, superconducting devices, etc., can solve the problem of affecting and changing the original performance of superconducting conductors, superconducting conductor stress recovery Deformation, low product qualification rate and other problems, to achieve the effect of simple and convenient operation and maintenance, small error, and simple processing and manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

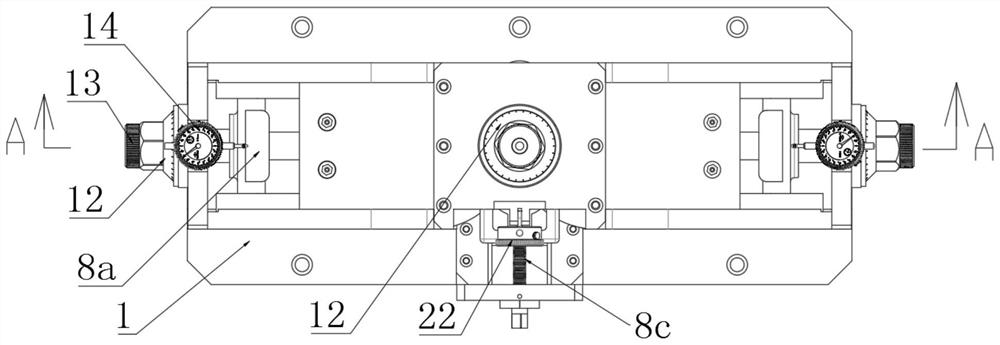

[0037] In embodiment 2, the 1st - 2nd grades are elliptical deformation models with different curvature or ellipticity, the 3rd - 5th grades are respectively the same or different plane deformation models with the same or different deformation amount or elongation, and the 6th grade Level -7 is a plane deformation model with the same deformation or elongation. The rest of the structure and corresponding operation mode of this example can be similar to the above-mentioned embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com