Environmental regeneration device for waste oil

A regenerative device and environmentally friendly technology, applied in the direction of lubricating compositions, etc., can solve the problems of high energy consumption and dangerous production process of high-temperature distillation, and achieve the effect of low energy consumption and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

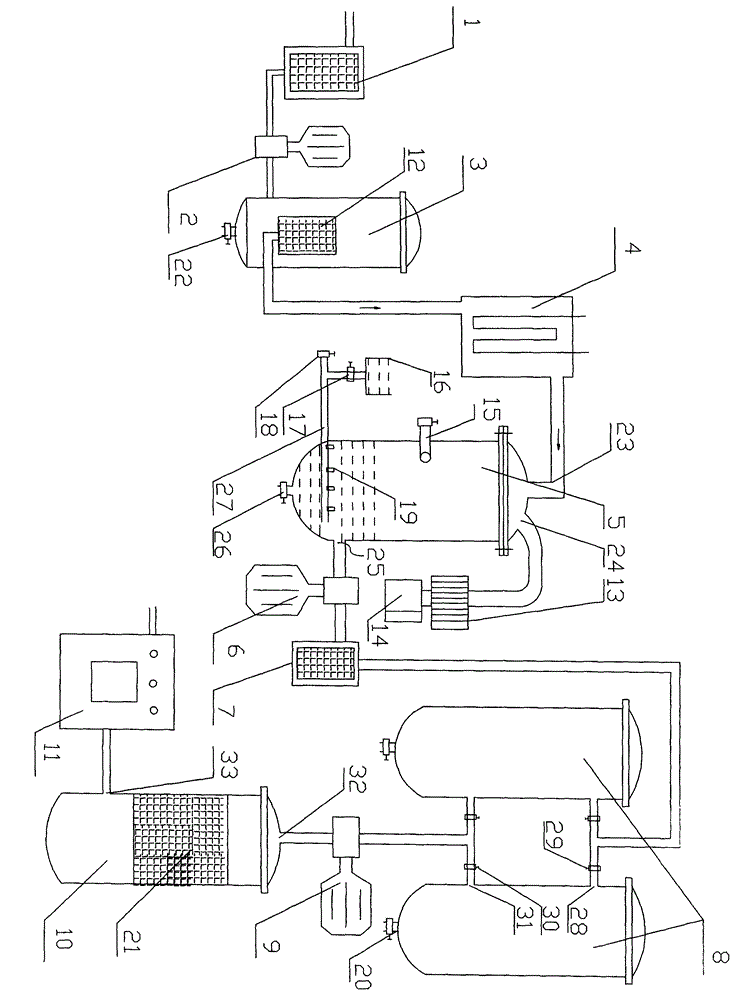

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0012] like figure 1 As shown, the waste oil environmental protection regeneration device of the present embodiment is composed of a coarse filter 1, an oil pump I2, a water separator 3, a heater 4, a vacuum stirring dehydration tank 5, a condenser 13, a vacuum pump 14, a dosing tank 16, and an oil pump II6 , fine filter 7, sedimentation tank 8, oil pump III9, decolorization tank 10, electrostatic oil filter 11, etc. are connected to each other through valves and pipelines.

[0013] The water separator 3 is a detachable sealed tank with a water-separating filter element 12 inside. The vacuum stirring and dehydrating tank 5 is a closed tank structure. There is an oil inlet I23 in the center of the top, and the oil inlet I23 is connected to the heater tube 4 tube connection. There is a suction port 24 on the top side and is connected to the va...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap