Conveying device and method for removing rod breaking on table board of combing machine

A conveying device, comber technology, applied in the direction of comber, textile and papermaking, fiber processing, etc., can solve problems such as accidental elongation, reduce tension and friction, stabilize transportation, and eliminate accidental elongation and breakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the present invention clearer, the present invention will be further described in detail below in conjunction with polyester-cotton blended examples and accompanying drawings.

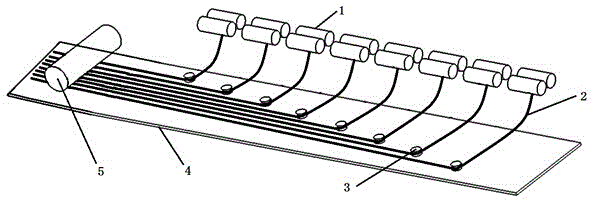

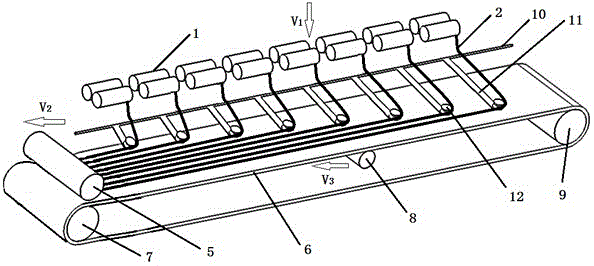

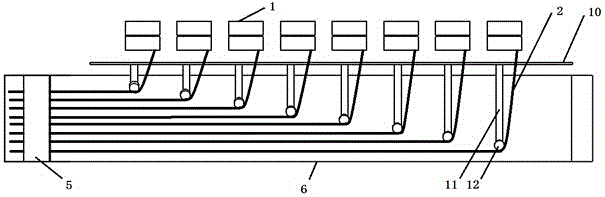

[0021] A conveying device for eliminating broken sliver on the combing machine table, such as figure 2 , image 3 with Figure 4 As shown, it includes a pressure roller 1, a table guide roller 5, and also includes a guide device and a table conveying device positioned at the lower end of the table guide roller 5. The table guide roller 5 is fixed on the wallboard in the combing locomotive.

[0022] The table conveying device comprises a table conveyor belt 6 , a conveyor driven wheel 7 , a conveyor roller 8 and a conveyor driving wheel 9 . Conveyor belt driven wheel 7, conveyor belt idler 8 and conveyor belt driving wheel 9 are fixed on the wallboard in the combing locomotive. The table conveyor belt 6 is located below the pressure roller 1, and the table guide roller 5 is ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap