Anti-leakage pulp circulation intelligent pulping and pressing system

A leak-proof slurry and slurry-making technology, which is applied in the installation of bolts, mining equipment, construction, etc., can solve the problems of easy slurry leakage, damage to the grouting machine, and insufficient fineness of the slurry, so as to avoid the accumulation of slurry in the pipeline and avoid Pipe rupture, good pulping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

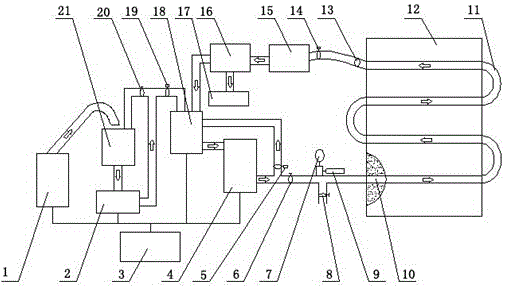

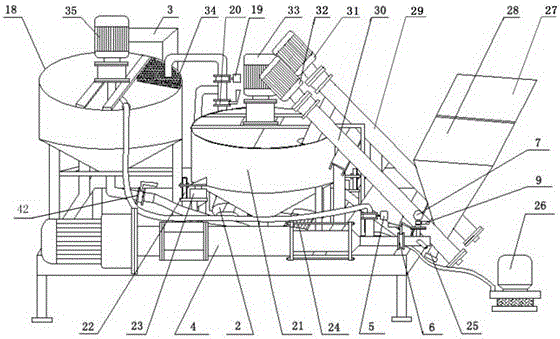

[0028] Such as figure 1 , 2 As shown, the inlet and outlet ends of the circulating pump 2 of the present invention are connected to the high-speed stirring pulping barrel 21 to form a circulating pump and its circulation loop with the high-speed stirring pulping barrel; it is used to circulate and stir the slurry at a high speed to make the slurry more delicate , evenly.

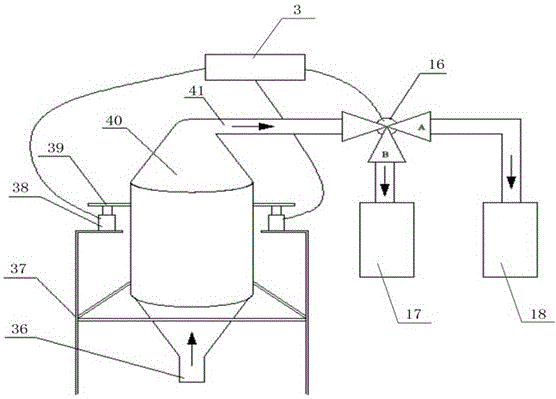

[0029] In the discharge pipeline of the pulper 4, a low-speed stirring circulation pipeline connected to the low-speed stirring pulp storage tank 18 is set to form a circulation circuit between the pulp press machine and the low-speed stirring pulp storage tank, and the functions can be realized: 1. Prevent the pulper from 2. Avoid slurry accumulation in the pipeline connecting the storage tank and the screw pump; 3. Avoid pipeline rupture caused by excessive pressure when the grouting valve is closed; 4. Use it to clean the equipment after grouting is completed.

[0030] The conveying pipeline of the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com