An automatic steel bar binding machine

A binding machine and steel bar technology, applied in the field of steel bar binding, can solve the problems of high cost, difficulty in popularization, and large volume, and achieve the effects of easy operation and use, reduced manufacturing cost, and good knotting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

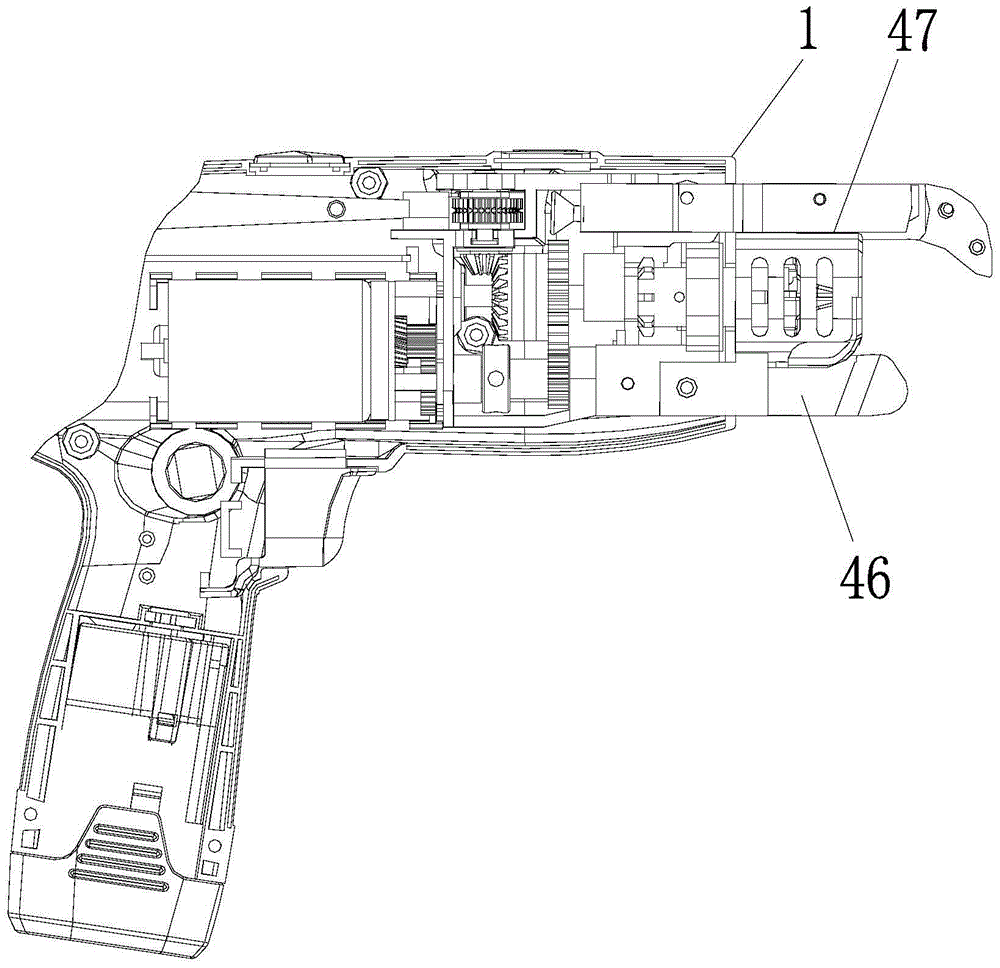

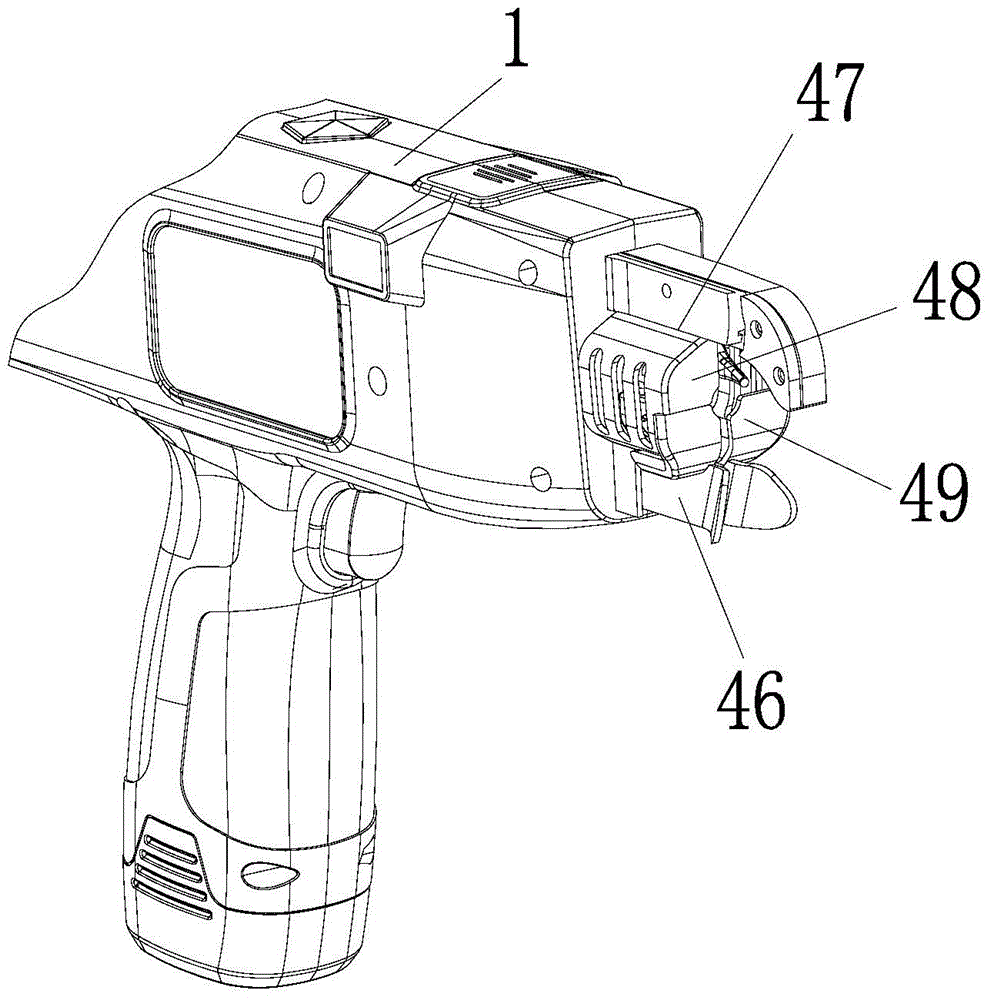

[0049] An automatic steel bar binding machine, comprising a casing 1, a motor 2, a wire feeding mechanism 3, a wire cutting mechanism 4, a transmission system 5 and a wire twisting mechanism 6, the twisting mechanism 6 includes a rotating rod 7, a chuck 8, an anti-off Mechanism 9, sleeve 10 and spring 11, said rotating rod 7 has threaded section 12, and said collet 8 comprises collet body 13 and twisted wire claw 14, and collet body 13 has spring chamber 15 at one end, and the other end is connected with The twisted claws 14 are hinged, the spring 11 is installed in the spring chamber 15, and the front end of the rotating rod 7 extends into the spring chamber 15 of the collet body 13 and is connected to the spring chamber 15 and the spring 11 through the anti-off mechanism 9. connected;

[0050] The outer surface of the sleeve 10 has a transmission toothed belt, and the transmission toothed belt includes one long tooth 16 and seven short teeth 17, and the inner surface of the ...

Embodiment 2

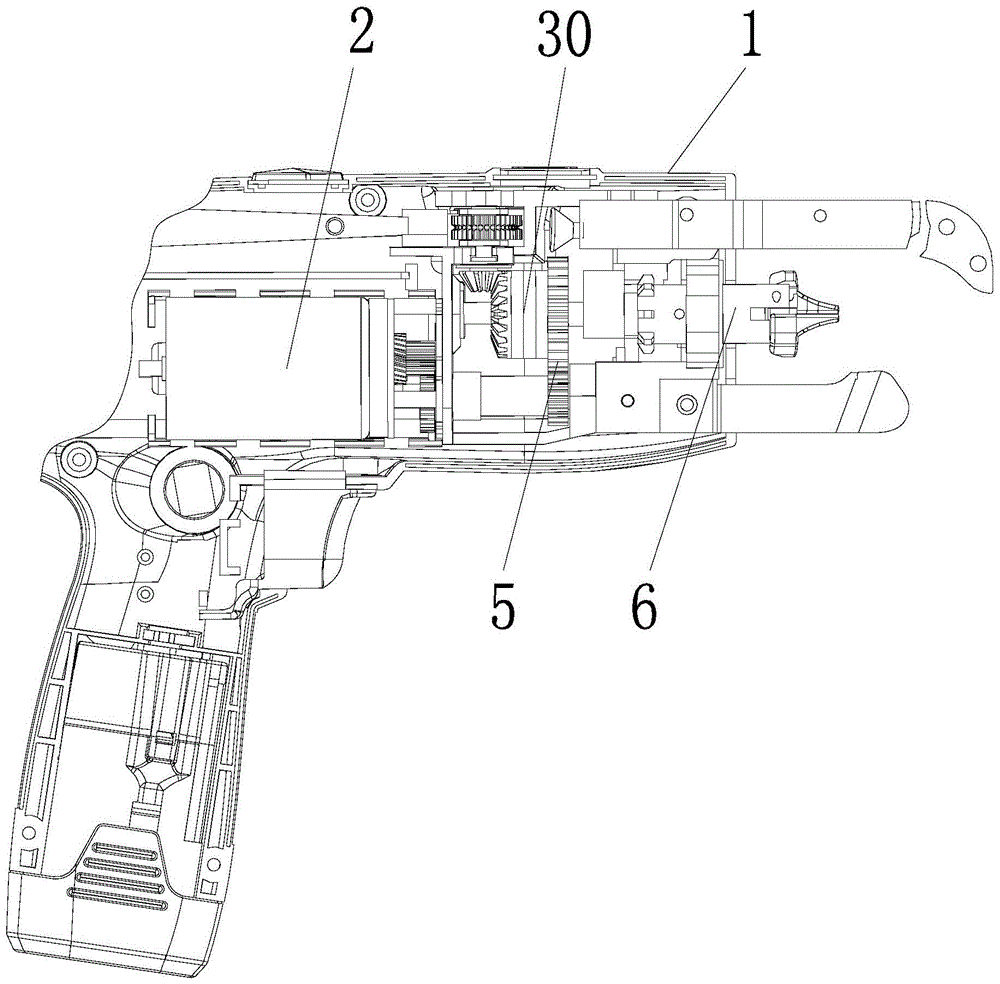

[0067] This embodiment differs from Embodiment 1 in that: the transmission system 5 includes a buffer mechanism 30 and a power input gear 31, and the power input gear 31 has an arc-shaped first buffer chute 32 on one side, and the buffer mechanism 30 It includes an output wheel 33 and a buffer wheel 37. A first transmission block 34 protrudes from one side of the output wheel 33, a second transmission block 38 protrudes from one side of the buffer wheel 37, and an arc-shaped first transmission block 38 protrudes from the other side. Two buffer chute 39, the second transmission block 38 is connected in the first buffer chute 32, and the first transmission block 34 is connected in the second buffer chute 39;

[0068] The sum of the radians of the first buffer chute 32 and the second buffer chute 39 is equal to or greater than the angle at which the rotating rod 7 makes the twisting claw 14 rotate from being tightly hugged to being opened;

[0069] The rotating rod 7 is transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com