Heat-storage and heat-preservation framework type greenhouse wall

A skeleton type, wall technology, applied in thermal insulation, greenhouse cultivation, wall and other directions, can solve the problems of low thermal insulation performance, high cost, easy cracking of the wall, etc., to improve thermal storage performance, improve thermal storage capacity, and resource efficient reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

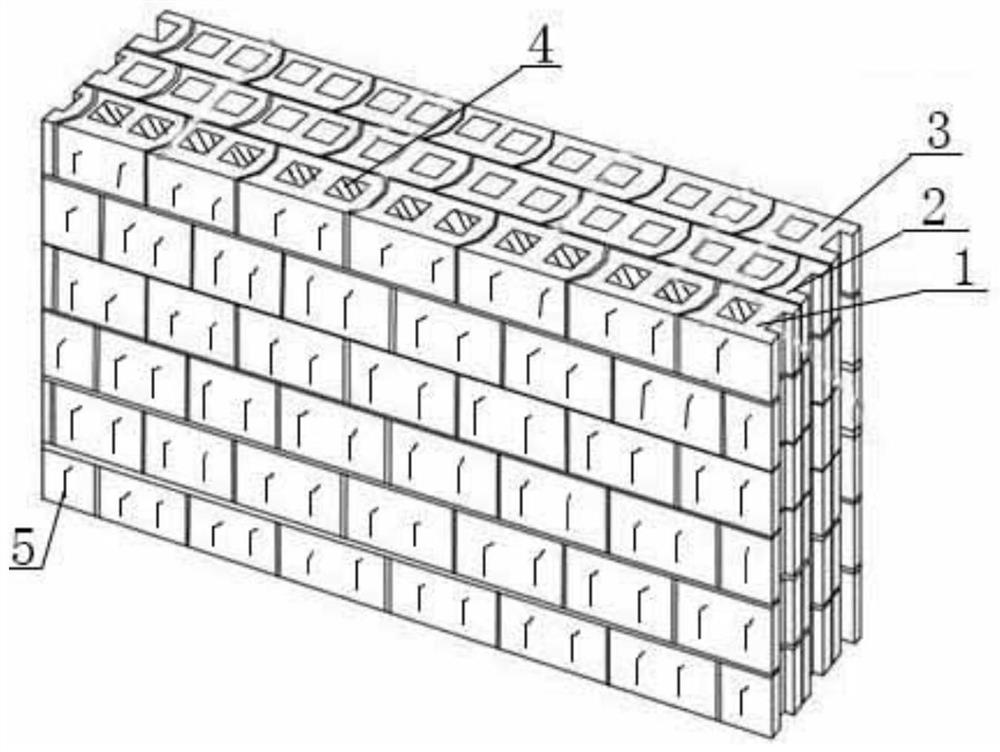

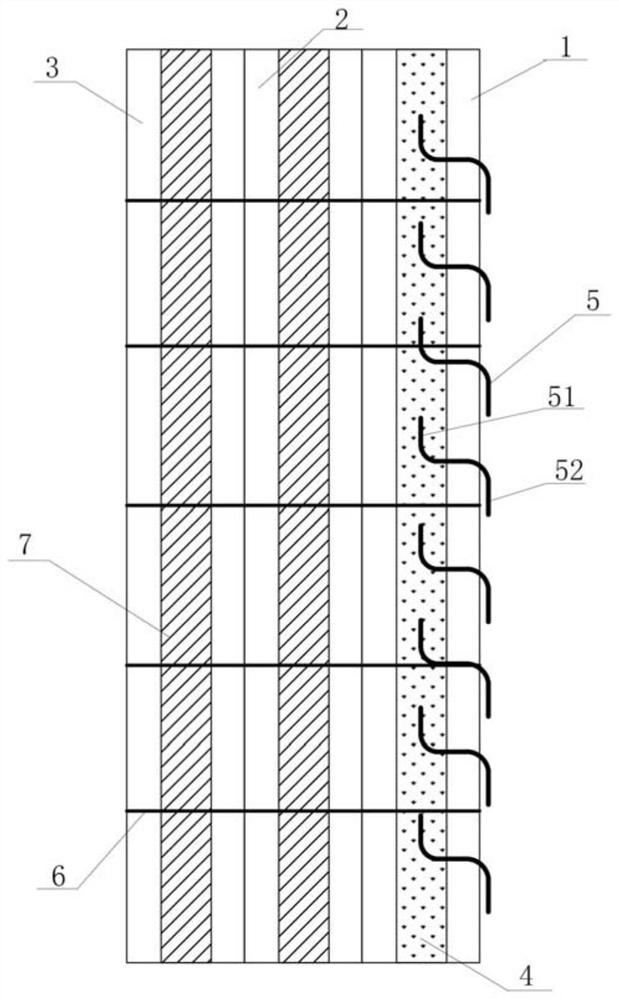

[0028] like Figure 1-2 The shown heat storage and heat preservation skeleton type greenhouse wall includes an inner layer 1, an intermediate layer 2 and an outer layer 3 arranged sequentially from the inside to the outside, and the inner layer 1, the middle layer 2 and the outer layer 3 are all made of hollow brick The inner layer 1, the middle layer 2 and the outer layer 3 are fastened and connected by tie bars 6; the middle layer 2 and the outer layer 3 are insulation layers, and the pores of the hollow brickwork The upper and lower alignment forms an air circulation channel 7; the inner layer 1 is a heat storage layer, and the pores of the hollow bricks are aligned up and down, and the pores are filled with a heat storage material 4, and the heat storage material is desert sand or soil .

[0029] The wall of the present invention adopts a three-layer structure, wherein the inner layer 1 is filled with heat storage materials, which can improve the heat storage performance ...

Embodiment 2

[0032] On the basis of the technical solution of Example 1, the wall also includes the following technical features:

[0033]The hollow bricks are prepared from the following raw materials in parts by weight: 300 parts of cement, 15 parts of rice husk powder, 3 parts of nano-silica, 800 parts of sand, 300 parts of industrial waste, 3 parts of water reducing agent, modified 9 parts of straw, 9 parts of metakaolin, and 150 parts of water.

[0034] The preparation method of described hollow brick is as follows:

[0035] S1. Collect straw and industrial waste, sieve, and reserve;

[0036] S2. Put the collected and sieved stalks into an 8% NaOH solution by mass, soak for 8 hours, then wash and dry; then spray 3% water glass on the dried stalks , to obtain modified straw.

[0037] S3. Mix and stir cement, rice husk powder, nano-silica and sand for 3 minutes, then add industrial waste residue and metakaolin, and stir for another 3 minutes, then add water, water reducing agent and ...

Embodiment 3

[0045] On the basis of the technical solution of Example 1, the wall also includes the following technical features:

[0046] The hollow bricks are prepared from the following raw materials in parts by weight: 400 parts of cement, 80 parts of rice husk powder, 20 parts of nano silicon dioxide, 1000 parts of sand, 400 parts of industrial waste residue, 4 parts of water reducer, modified 12 parts of straw, 12 parts of metakaolin, and 200 parts of water.

[0047] The preparation method of described hollow brick is as follows:

[0048] S1. Collect straw and industrial waste, sieve, and reserve;

[0049] S2. Put the collected and sieved straw into 10% NaOH solution by mass, soak for 8h, then wash and dry; then spray the pure acrylic acid polymer solution of 3% by mass after drying on the straw to obtain the modified straw.

[0050] S3. Mix and stir cement, rice husk powder, nano-silica and sand for 3 minutes, then add industrial waste residue and metakaolin, and stir for another...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com