Pressurizing device for fully hydraulically driven downhole pipe string and its propulsion method

A technology of downhole pipe strings and pressurization devices, which is applied in drilling equipment and methods, rotary drilling rigs, buildings, etc., can solve problems such as difficult to meet complex field conditions and unsatisfactory effects, and achieve improved oil field production capacity and guaranteed efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The above and other technical features and advantages of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them.

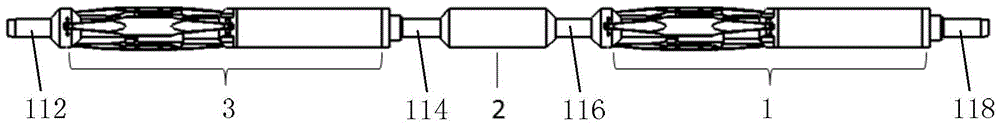

[0061] see figure 1 As shown, a fully hydraulically driven downhole pipe string pressurization device of the present invention includes a second actuating mechanism 3 , a hydraulic control center 2 and a first actuating mechanism 1 connected in sequence.

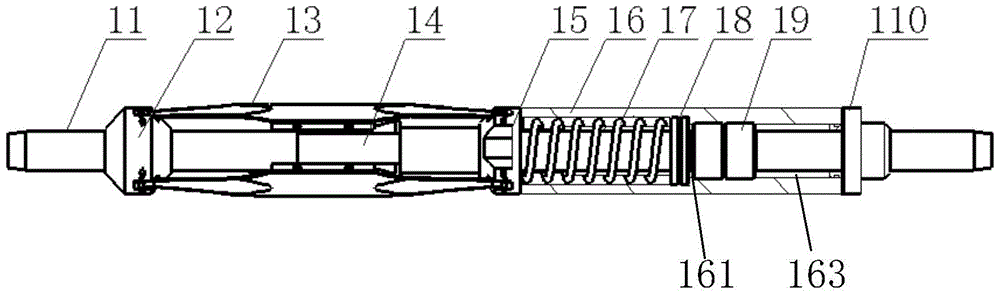

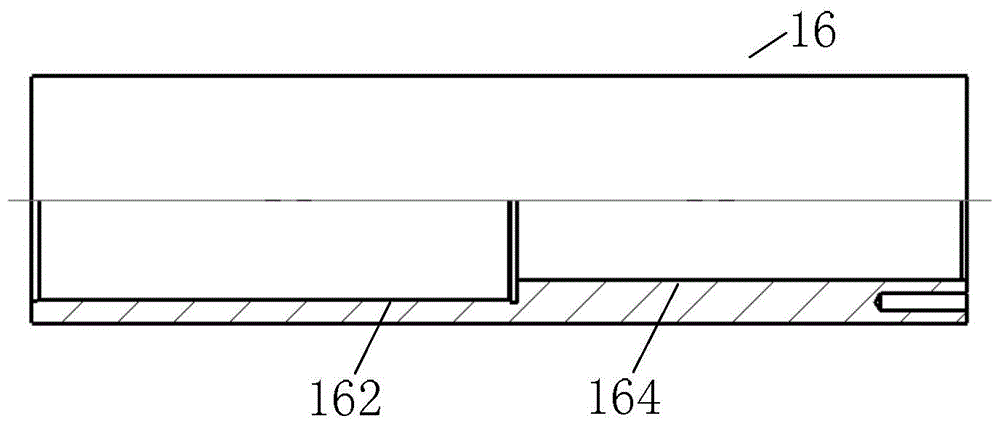

[0062] see figure 2 As shown, the first actuating mechanism 1 and the second actuating mechanism 3 both include an anchor assembly, a hydraulic cylinder 16 and a push piston 19 arranged in sequence; the push piston 19 is fixedly connected to a center pipe 11, and the center pipe 11 runs through the anchor assembly and the hydraulic Cylinder 16, in this embodiment, the central pipe 11 protrudes from the anchor assembly and the hydrau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com