Method and device for shocking by circulating drilling fluid

A technology of circulating drilling fluid and drilling fluid, which is applied in the direction of earthwork drilling, wellbore/well components, etc., can solve the problems of jar failure and other problems, and achieve the effect of overcoming a single jar and reducing the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

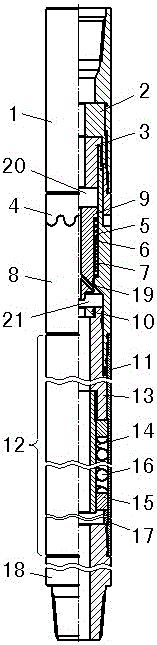

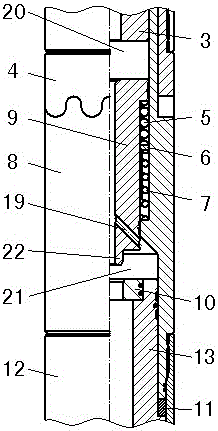

[0023] During specific implementation, one end of the upper joint 1 is processed with a rectangular spline groove, the spline body 2 is loaded into the upper joint 1 through the spline pair, the throttle body 3 at the lower end directly withstands the step of the inner hole of the spline body 2, and the transmission sleeve 4 and the joint The fluid upper joint is threaded, the transmission sleeve 4 and the transmission shaft 8 are matched by a spline pair, and the transmission shaft 8 is threaded with the spline body 2, and the upper end hole of the transmission shaft 8 is equipped with a thick spring 5 and a thin spring 7 And spring guide sleeve 6 and piston 9. A valve seat 10 is installed on the upper end of the transmission shaft 8, a spring seat 15, an energy storage spring 16 and an adjustment sleeve 17 are installed on the lower end, and the transmission shaft 8, the middle cylinder 12, and the lower joint 18 are integrally connected by threads.

[0024] Below the course...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com