Turbine housing for exhaust turbocharger

A turbine housing and exhaust turbine technology, applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve the problems of inability to reduce heat, increase the weight of the overall exhaust turbocharger, etc., and achieve the effect of reducing heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

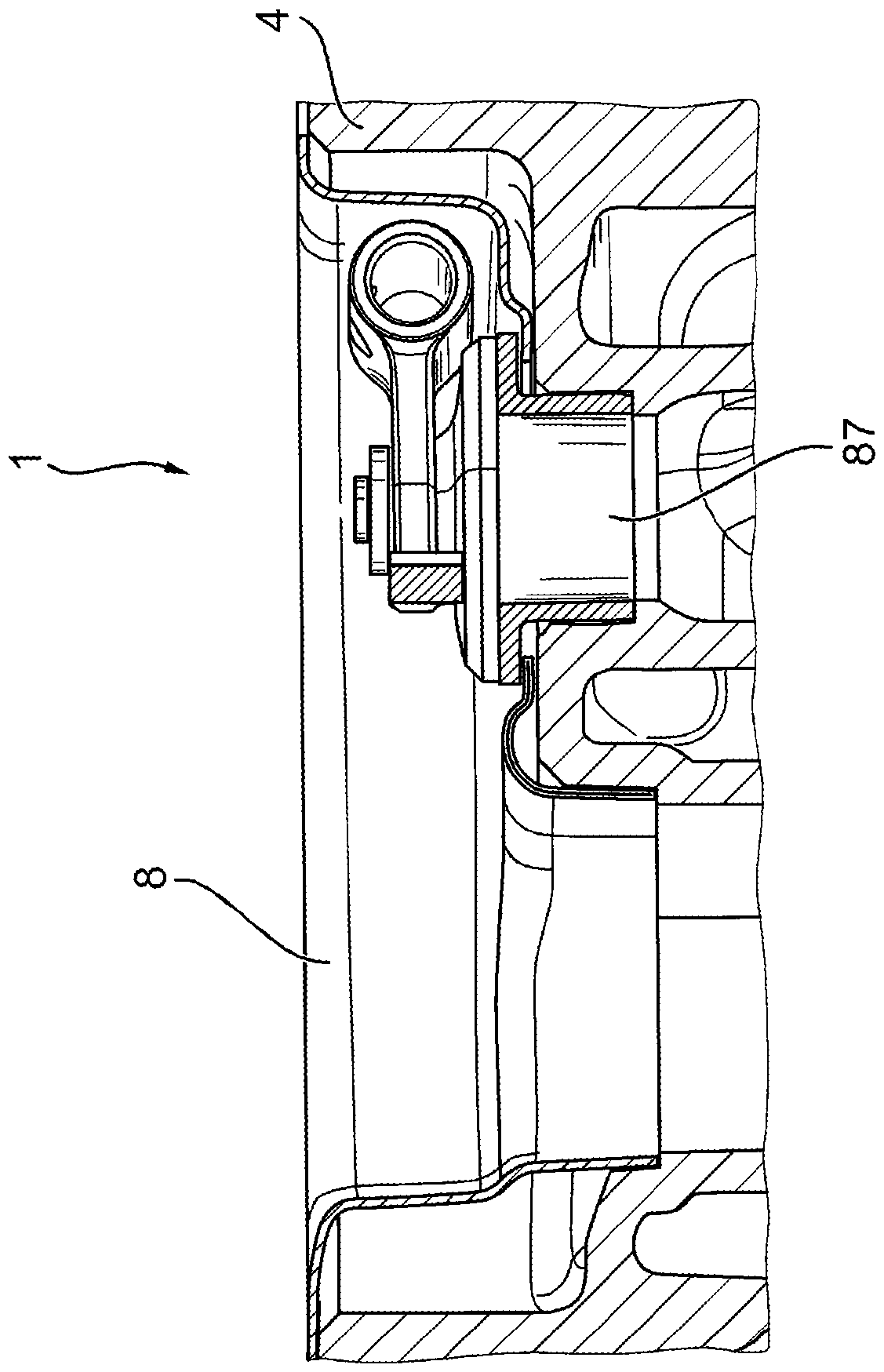

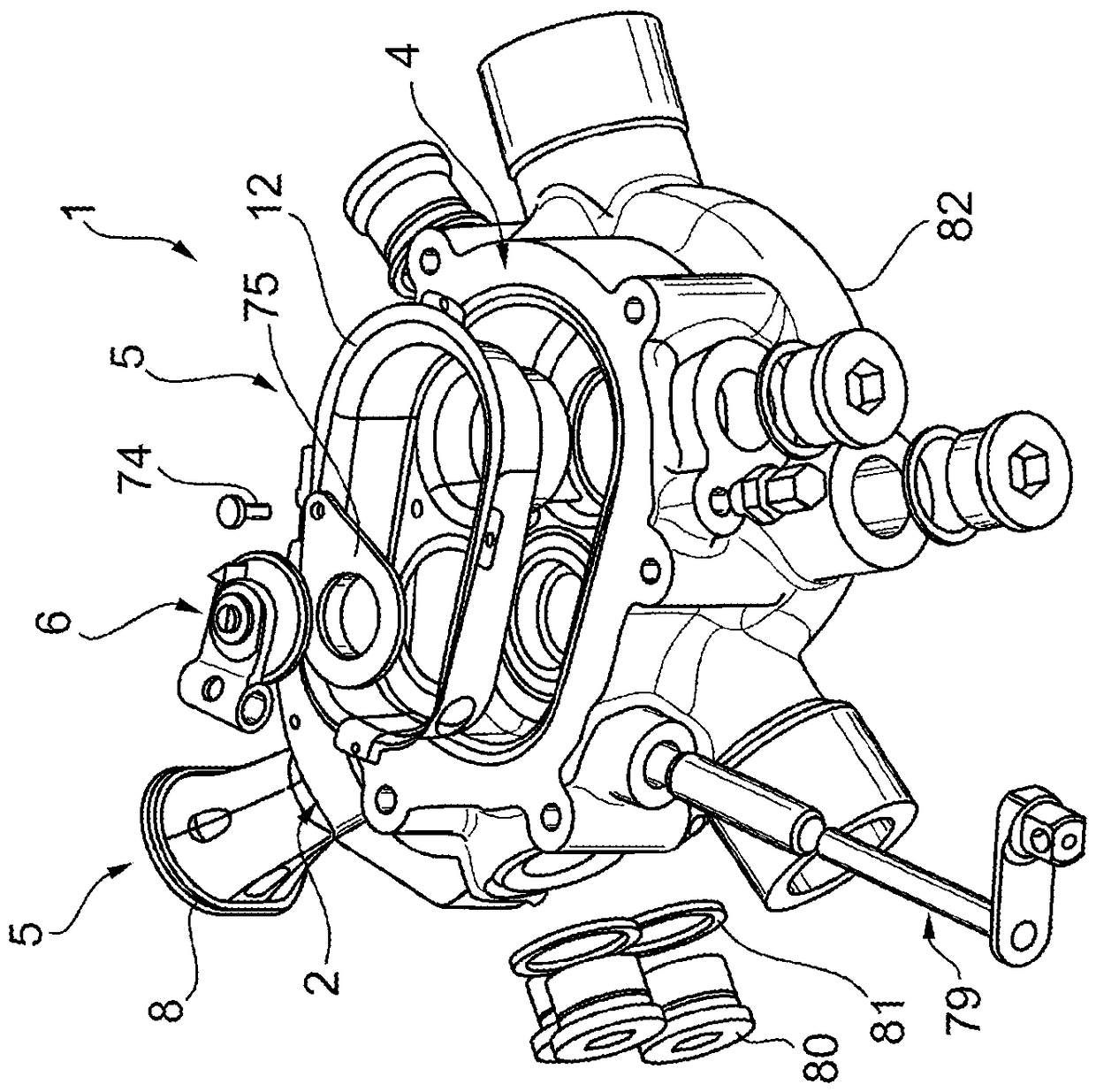

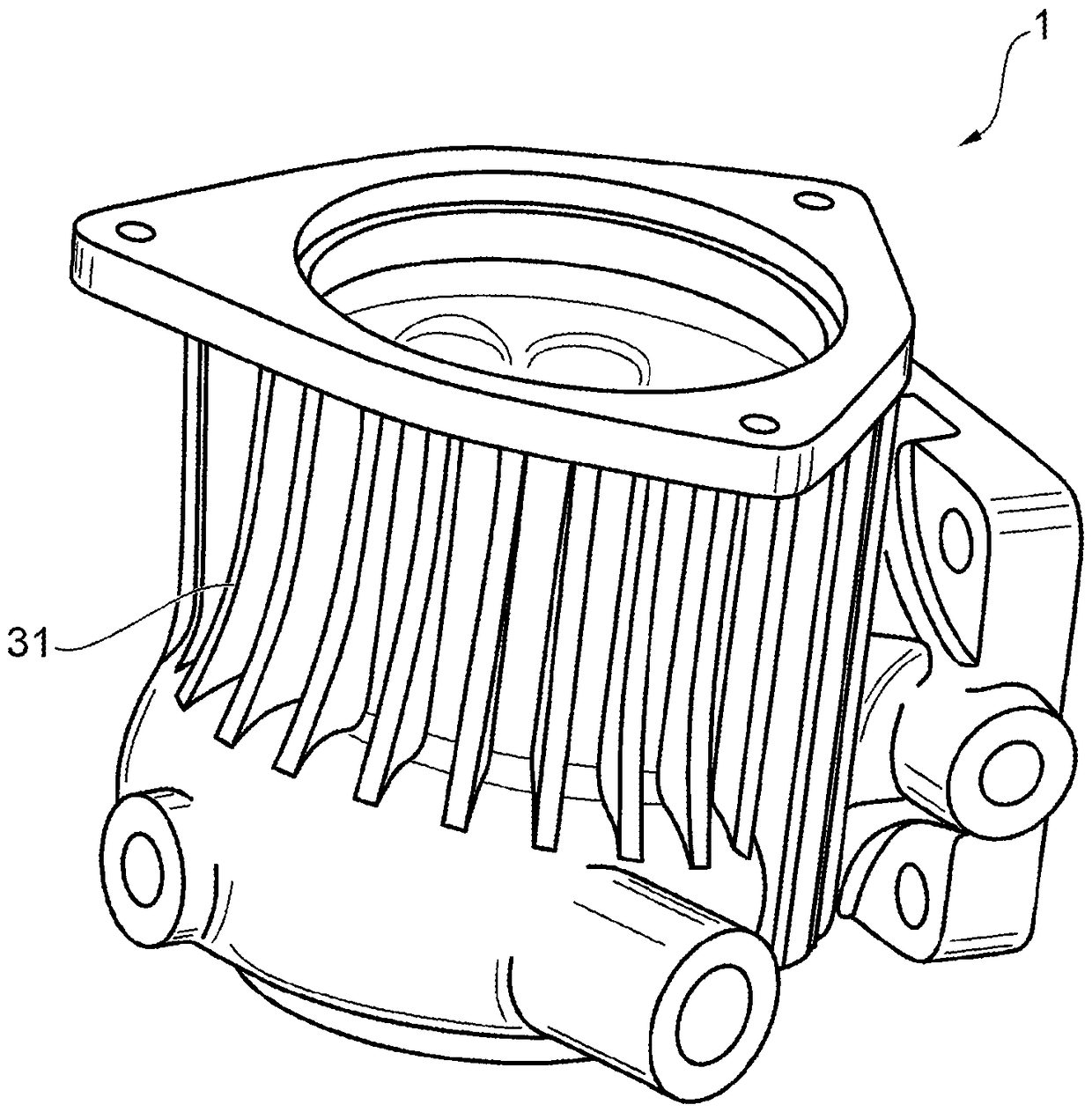

[0041] figure 1 A first embodiment of a turbine housing 1 according to the invention is shown, which has an inlet connection 2 and an outlet connection 4 . The spiral tube 3 is arranged between the inlet connection 2 and the outlet connection 4 . figure 1 Also shown is a wastegate arrangement 6 and an insulating device 5 , which is intended to reduce the heat input and which is arranged in this example in the region of the inlet connection 2 . exist figure 1 In the shown embodiment, this isolating means 5 is in the form of a sleeve or an insert part 8, as in figure 1 As can be seen in the drawing of , the spacer extends in this example in a slightly tapered design. This sleeve 8 extends from a fastening part 9 to a free end part 9', by means of which the sleeve 5 can be fixed to the inlet connection part 2, and the free end part extends in the inlet connection part 2. into the transition zone into the helical tube 3. In this example, the sleeve 8 is equipped with a spacer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com