Intelligent sampling and quality testing system and method for grain depot

A technology of sampling and grain depot, which is applied in the fields of sampling and quality inspection of grain depots, which can solve the problem of inability to prevent collusion and fraud between staff and sample senders, and difficulty in ensuring the accuracy of quality inspection information. Check the synchronization of sample information, the inconsistency of sample information, etc., to achieve the effect of preventing manual fraud, eliminating manual fraud, and reducing the intensity of manual work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the drawings and specific embodiments.

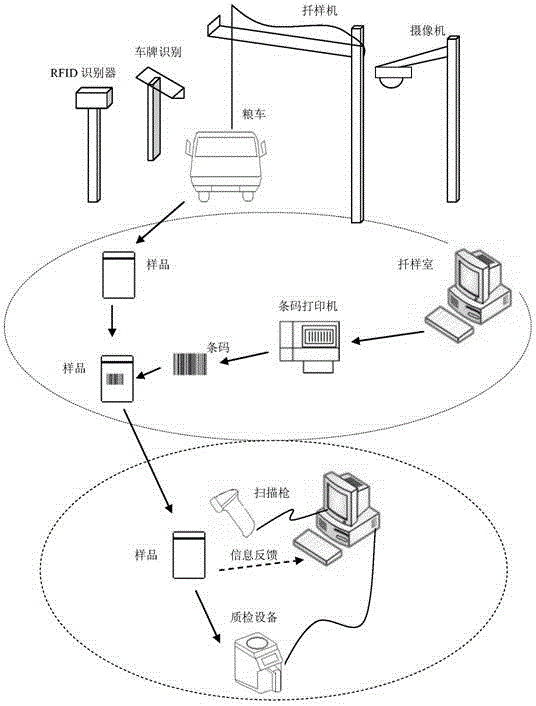

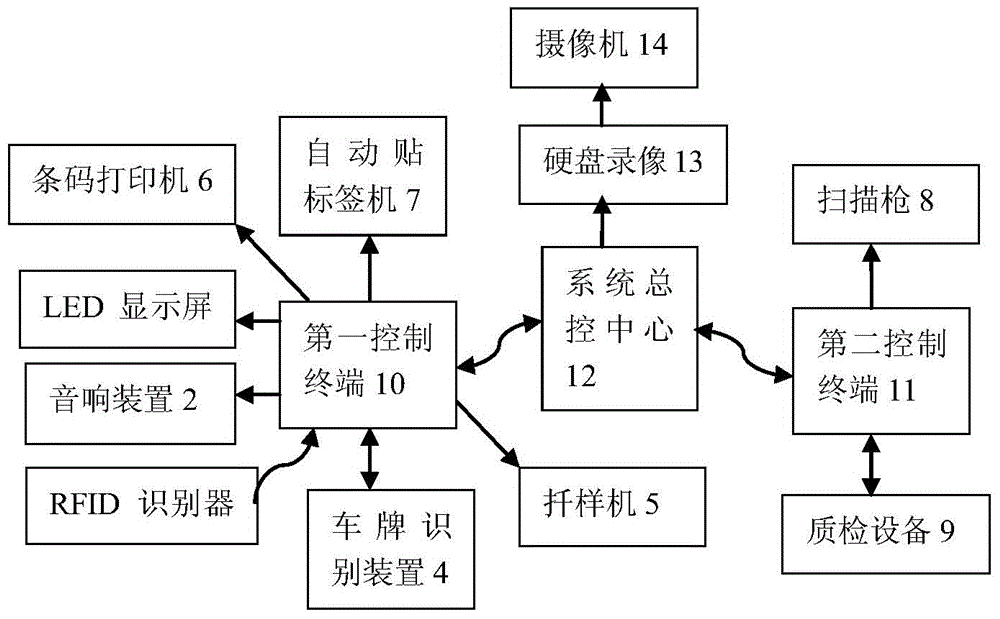

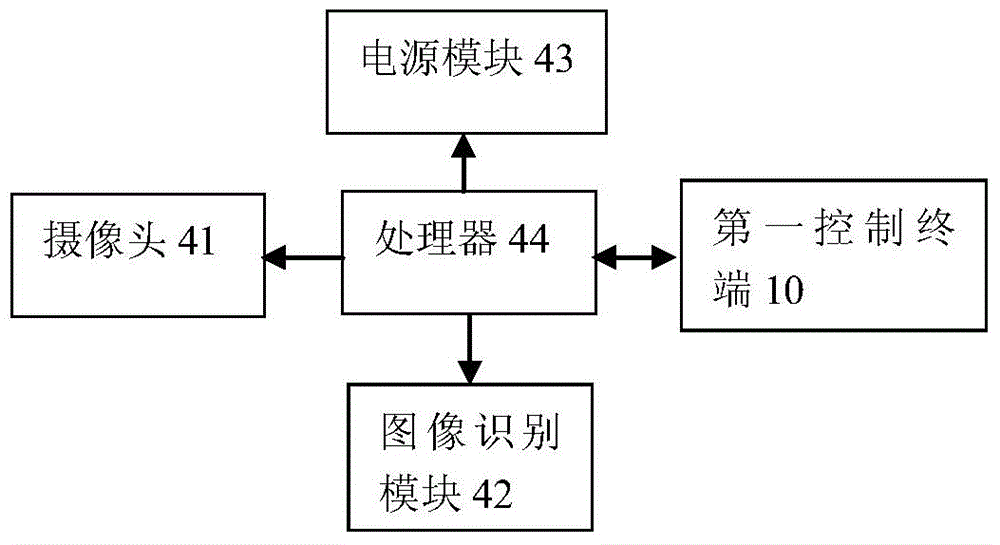

[0030] See figure 1 , figure 2 with image 3 , Is the intelligent skewer sample quality inspection system of the present invention, including LED display 1, audio device 2, RFID recognizer 3, license plate recognition device 4, vehicle positioning device, skewer 5, barcode printer 6, automatic labeling machine 7 , Scanning gun 8, quality inspection equipment 9, first control terminal 10, second control terminal 11, system control center 12, hard disk video recorder 13, and camera 14, wherein the license plate recognition device 4 includes a camera 41, an image recognition module 42, The power module 43 and the processor 44. The camera 41, the image recognition module 42, and the power supply module 43 are respectively electrically connected to the processor 44, and the processor 44 is electrically connected to the first control terminal 10.

[0031] The LED di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com