Intelligent factory control method and system

A factory control and process technology, applied in the field of intelligent factory control methods and systems, can solve problems such as not realizing integrated processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

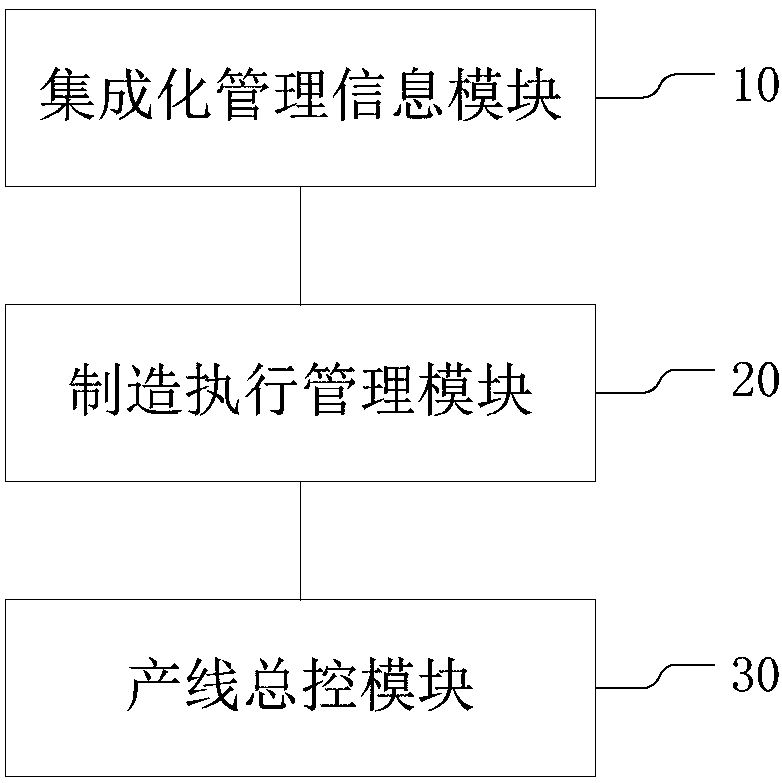

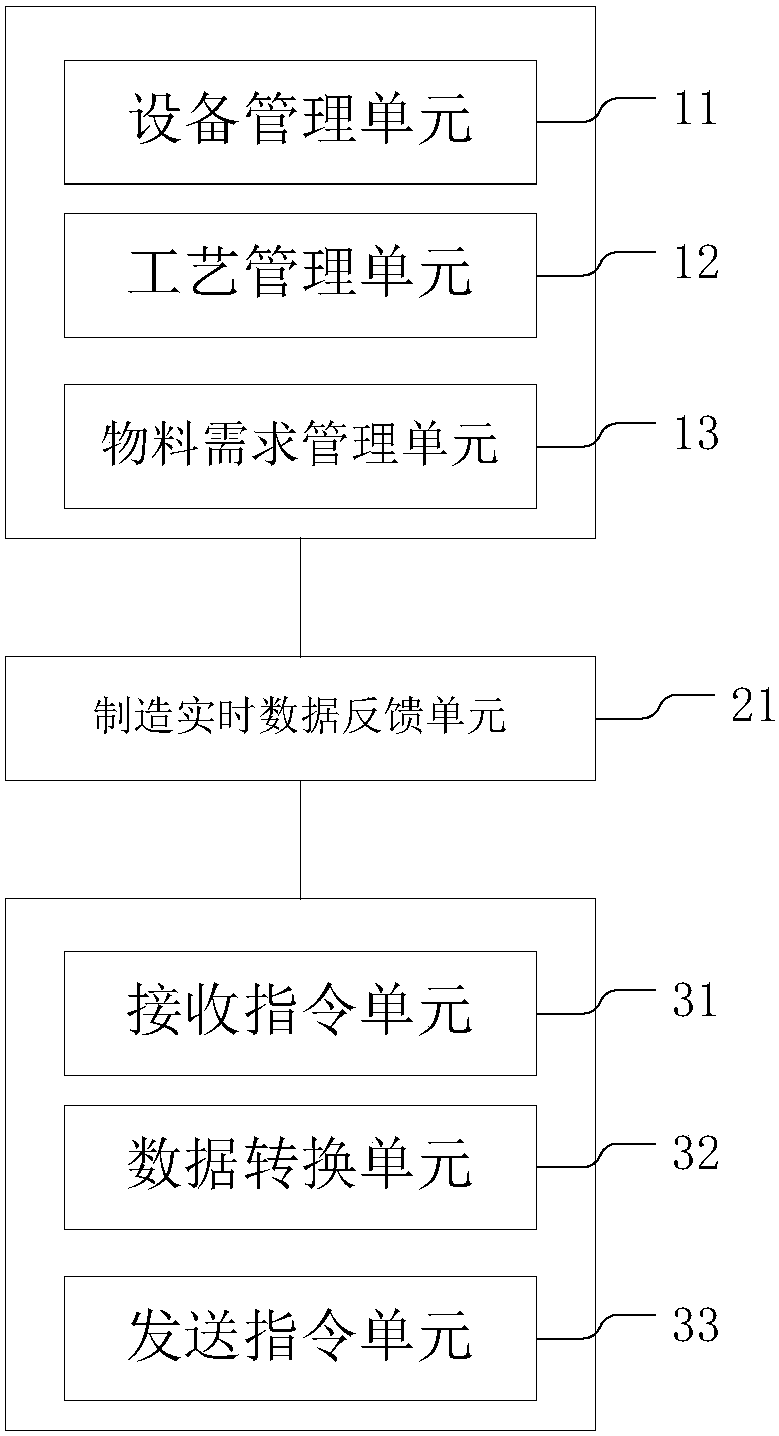

[0047] This embodiment provides an intelligent factory control system, such as figure 1 and figure 2 shown, including:

[0048] The integrated management information module is used to receive product demand information, process the received product demand information, and generate corresponding product orders and order process flow information cards;

[0049] The manufacturing execution management module is used to generate a corresponding production schedule according to the production order and the order process flow information card;

[0050] The production line master control module is used to control the production line to execute preset tasks through the production schedule and monitor the status and progress of each execution task in real time.

[0051] The product demand information includes:

[0052] Material data information, customer demand data information, equipment data information and process information.

[0053] Among them, the integrated management infor...

Embodiment 2

[0075] This embodiment provides an intelligent factory control method, such as Figure 3 to Figure 5 As shown, the details are as follows:

[0076] S1: Receive product demand information, process the received product demand information, and generate corresponding product orders and order process flow information cards;

[0077] S2: Generate a corresponding production schedule according to the production order;

[0078] S3: Control the production line to execute preset tasks through the production schedule and monitor the status and progress of each task in real time.

[0079] Further, the step S1 receiving product demand information includes:

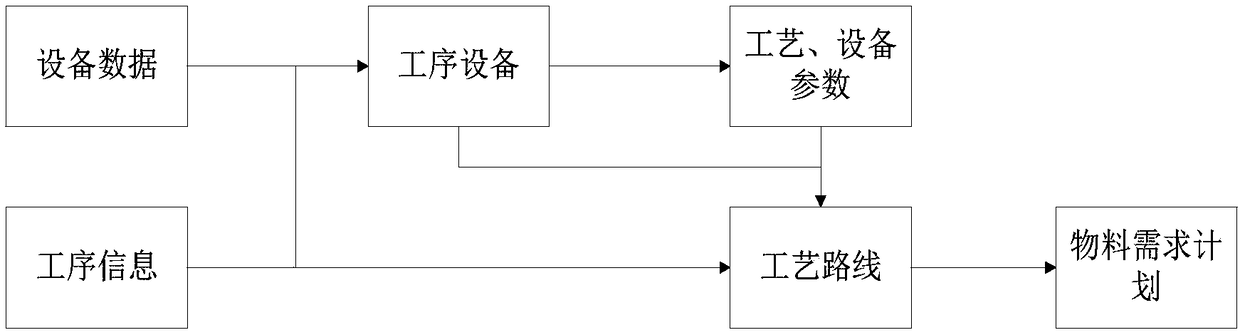

[0080] Receive material data information, customer demand data information, equipment data information and process information.

[0081] Further, the step S1 includes:

[0082] S11: Manage the equipment required for the allocation process and adjust equipment parameters;

[0083] S12: Receive the real-time data of the process produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com