Full-automatic mould-pressing demoulding penetration resistant testing machine

A fully automatic, anti-permeation technology, applied in the fields of permeability/surface area analysis, measuring device, suspension and porous material analysis, etc., it can solve problems such as hidden dangers of engineering quality, tediousness, affecting test work efficiency and data accuracy, etc., to achieve The effect of avoiding leakage and saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The technical solution of the present invention will be further described with the following embodiments in conjunction with the accompanying drawings.

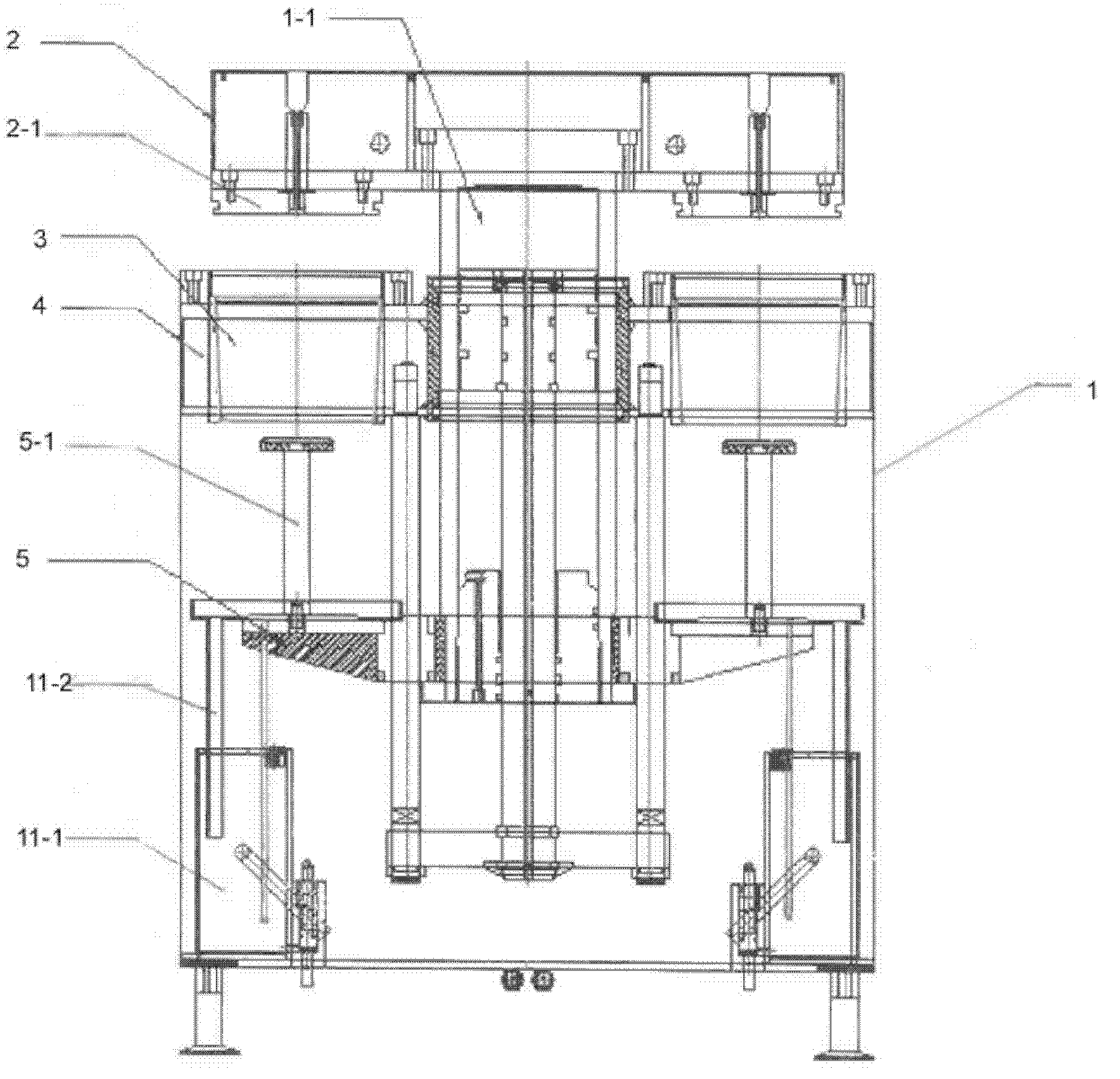

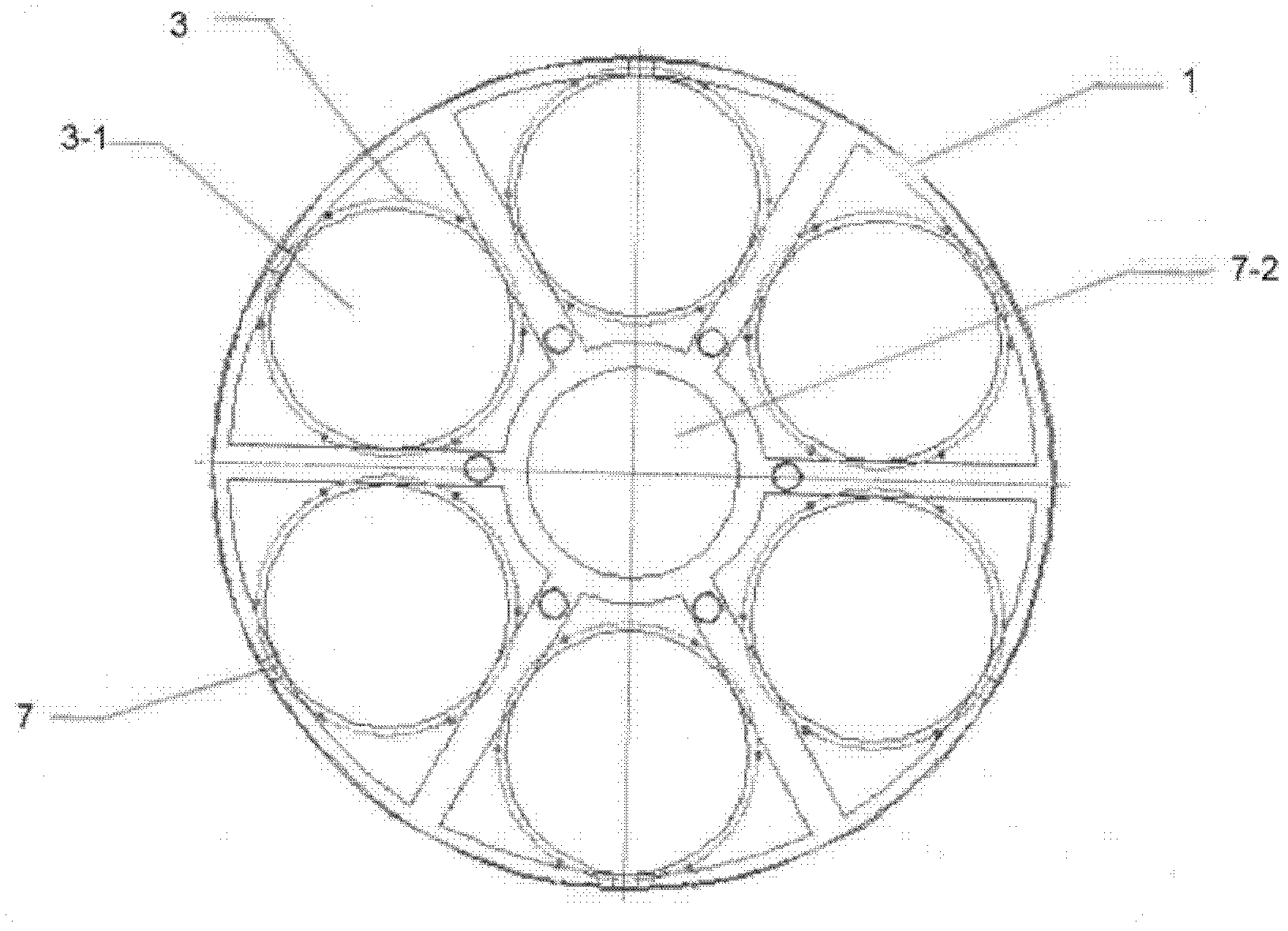

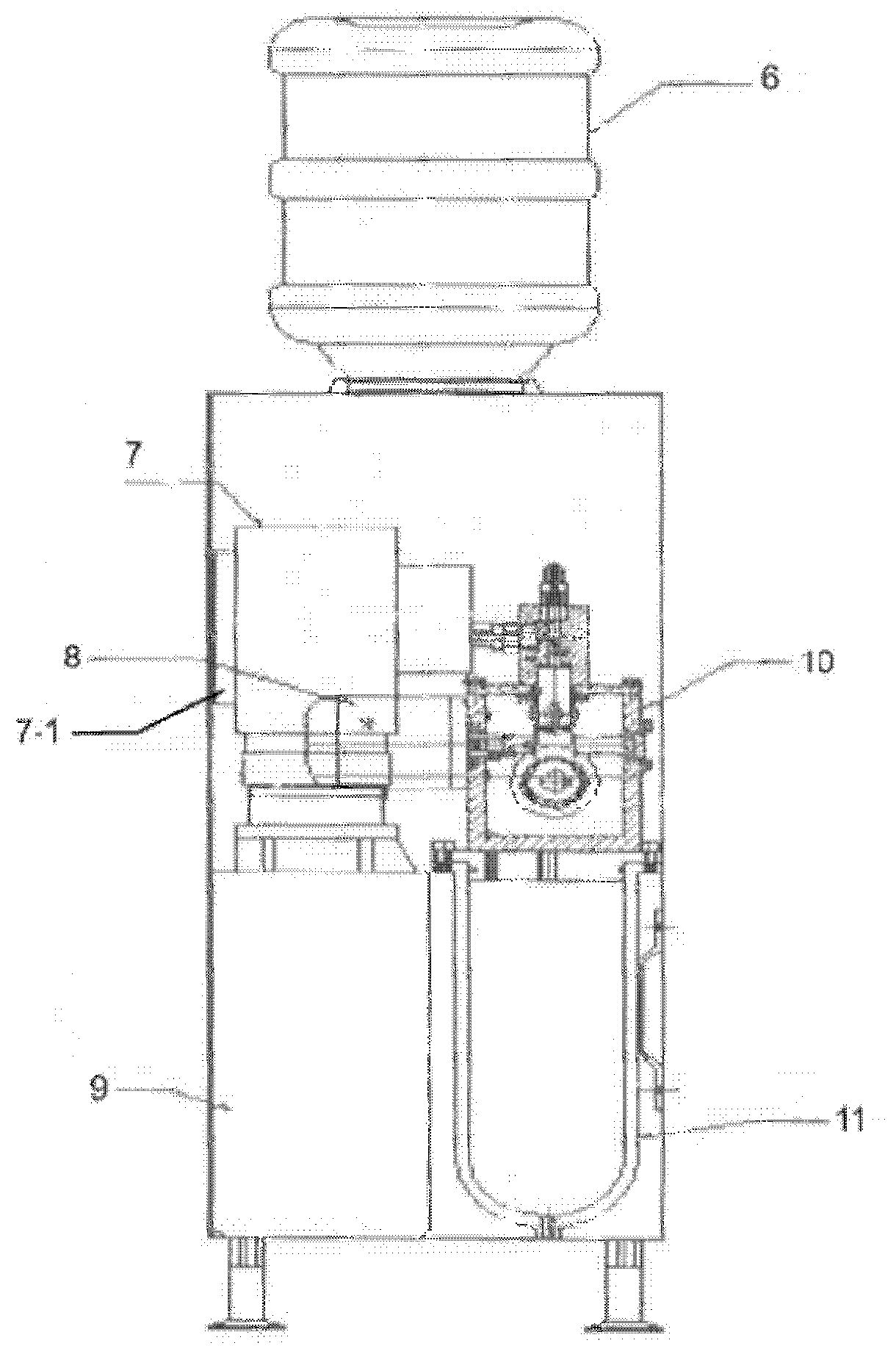

[0049] The full-automatic compression mold demoulding anti-penetration testing machine is divided into two parts, the main machine and the auxiliary machine. The main frame is cylindrical. The upper platen cover is installed on the upper part of the main machine, and the main oil cylinder 7-2 is installed in the center of the main body. There are six test mold sets 3 evenly distributed around the circumference of the main oil cylinder, and a test piece ejector pin 5-1 is installed under each test piece set. The cover plate assembly and the test piece ejector rod assembly are driven by the piston of the main oil cylinder to perform ascending, descending and hydraulic locking. Independent sealed oil bag 13 is housed in each trial mold cover, and oil bag is communicated with main oil cylinder by oil channel 18, oil inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com