Shower type wet texturing equipment and method for solar silicon wafers

A technology of solar silicon wafer and wet method, which is applied in the fields of final product manufacturing, sustainable manufacturing/processing, semiconductor/solid device manufacturing, etc., and can solve the problems of reduced uniformity of silicon wafer surface treatment, influence of silicon wafer quality, and areas of chemical concentration Inconsistencies in chemical concentration and other problems can be achieved to ensure the uniformity of corrosion, improve the degree of production automation, and balance the effect of liquid concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

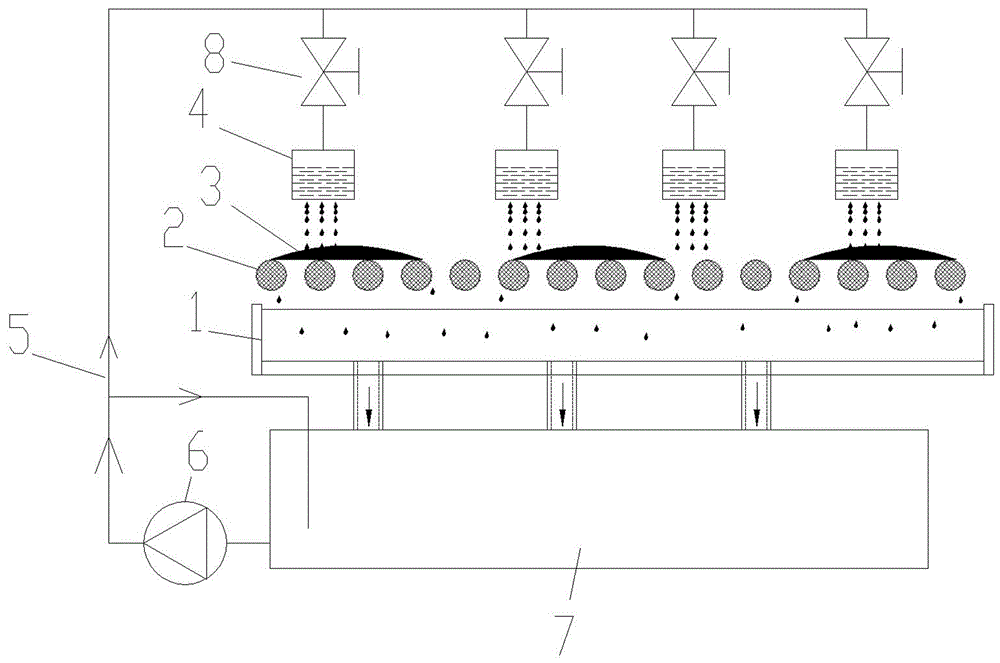

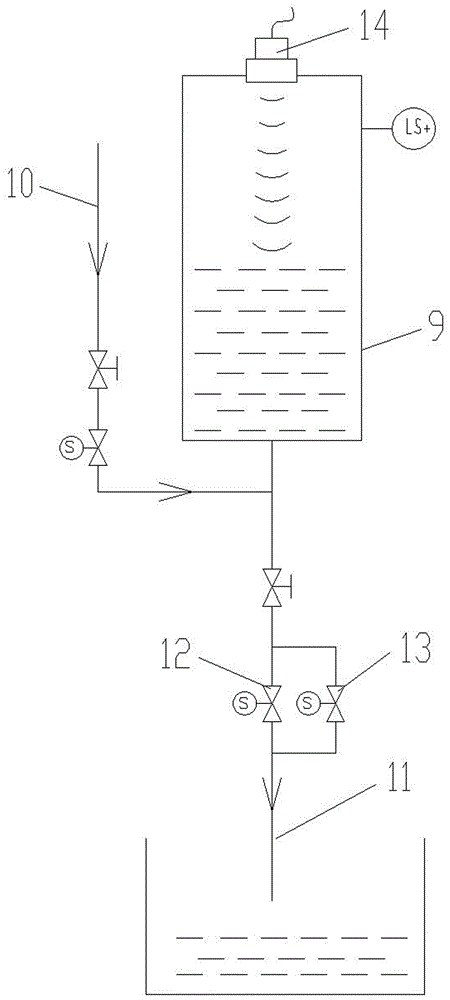

[0022] In the wet texturing treatment of solar silicon wafers, the silicon wafers are generally immersed in corrosive liquids for surface treatment, and the corrosive liquids participating in the reaction and the products after the reaction are mixed with the corrosive liquids that did not participate in the reaction, resulting in a reaction The concentration of the chemical solution in the tank is inconsistent regionally, which affects the production quality of the silicon wafer. The present invention uses a shower to spray or drop the corrosion solution on the silicon wafer, and the excess chemical solution and reaction products can flow back to the auxiliary tank in time. Avoid the problem of uneven drug concentration on the silicon wafer.

[0023] The shower-type wet texturing equipment for solar silicon chips proposed by the present invention includes: a conveying component, a spraying component and a liquid supply component.

[0024] The conveying assembly includes rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com