A kind of all-solid polymer electrolyte, its preparation method and application

A technology of all-solid polymers and electrolytes, applied in solid electrolytes, electrolyte battery manufacturing, non-aqueous electrolytes, etc., can solve the problems of low room temperature conductivity of electrolytes and the inability to use lithium-ion batteries, etc., and achieve low cost, good mechanical strength, Effect of High Ionic Conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

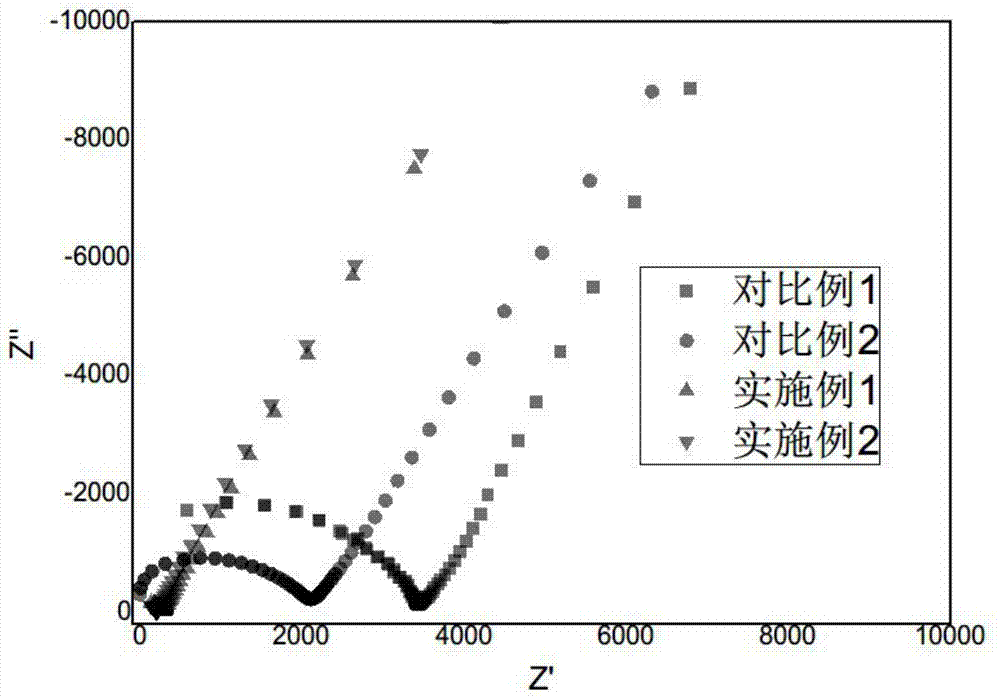

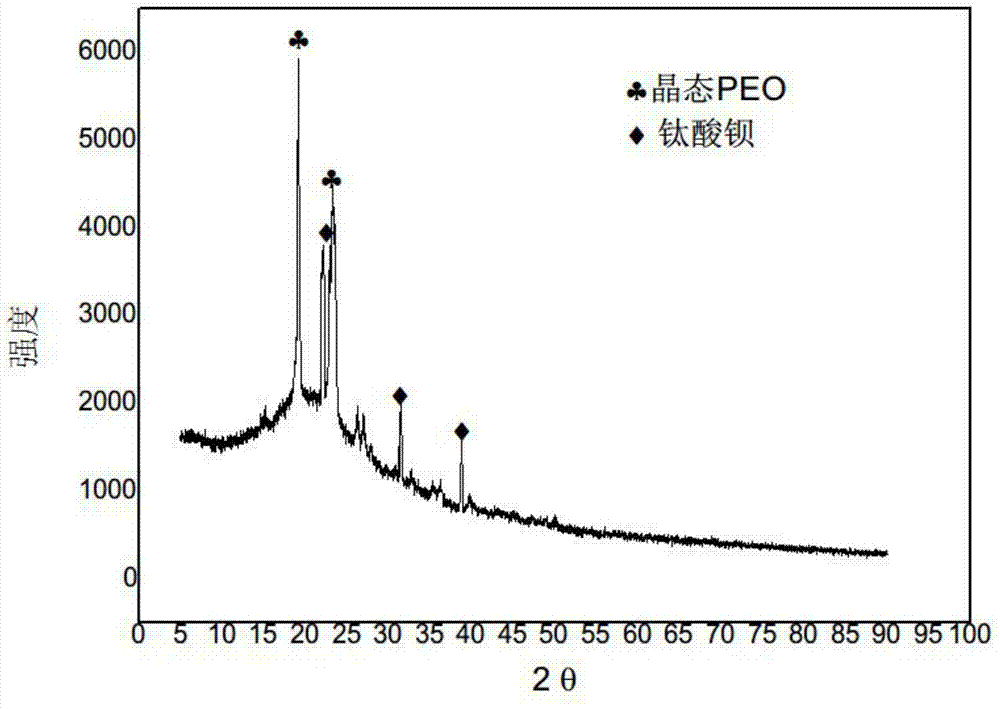

Embodiment 1

[0028] This example is used to prepare an all-solid polymer electrolyte with a thickness of 100 μm, and its components include: polyethylene oxide with a molecular weight of 600,000, lithium trifluoromethanesulfonimide, barium titanate with a particle size of 10 nm, ion Liquid 1-butyl-1-methylpyrrolidine bistrifluoromethylsulfonimide. Wherein, the mass ratio of the lithium salt to the polyethylene oxide is 0.36, and the sum of the mass of the inorganic nanoparticles and the ionic liquid is 10% of the mass of the all-solid polymer electrolyte. The ionic liquid is liquid, and its trace exists in the all-solid polymer electrolyte, and the ionic liquid is not volatile.

[0029] Its preparation method is as follows:

[0030] S1: First mix lithium trifluoromethanesulfonylimide with organic solvent acetonitrile, then add barium titanate with a particle size of 10nm and ionic liquid 1-butyl-1-methylpyrrolidine bistrifluoromethylsulfonyl amine, then magnetically stirred for 60 min, a...

Embodiment 2

[0037] This example is used to prepare an all-solid polymer electrolyte with a thickness of 300 μm, and its components include: polyethylene oxide with a molecular weight of 800,000, lithium tetrafluoroborate, zirconia with a particle size of 100 nm, and ionic liquid 1-butyl -1-Methylpyrrolidine bistrifluoromethylsulfonimide. Wherein, the mass ratio of the lithium salt to the polyethylene oxide is 0.5, and the sum of the mass of the inorganic nanoparticles and the ionic liquid is 30% of the mass of the all-solid polymer electrolyte. The ionic liquid is liquid, and its trace exists in the all-solid polymer electrolyte.

[0038] Its preparation method is as follows:

[0039] S1: First mix lithium trifluoromethanesulfonylimide with organic solvent acetone, then add zirconia with a particle size of 100nm and ionic liquid 1-butyl-1-methylpyrrolidine bistrifluoromethylsulfonylimide , and then magnetically stirred for 30 min, and finally added polyethylene oxide powder with a molecul...

Embodiment 3

[0045] This example is used to prepare an all-solid polymer electrolyte with a thickness of 120 μm, and its components include: polyethylene oxide with a molecular weight of 1 million, lithium perchlorate and lithium hexafluorophosphate, silicon oxide with a particle size of 50 nm, and ionic liquid 1- Butyl-1-methylpyrrolidine bistrifluoromethylsulfonimide. Wherein, the mass ratio of the lithium salt to the polyethylene oxide is 0.1, and the sum of the mass of the inorganic nanoparticles and the ionic liquid is 15% of the mass of the all-solid polymer electrolyte. The ionic liquid is liquid, and its trace exists in the all-solid polymer electrolyte.

[0046] Its preparation method is as follows:

[0047] S1: Lithium perchlorate, lithium hexafluorophosphate, and organic solvent tetrahydrofuran were mixed first, then silicon oxide with a particle size of 50 nm and ionic liquid 1-butyl-1-methylpyrrolidine bistrifluoromethylsulfonimide were added, and then Stir magnetically for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com