Drive system and method of driving a vehicle

A drive system, vehicle technology, used in hybrid vehicles, motor vehicles, electric vehicles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

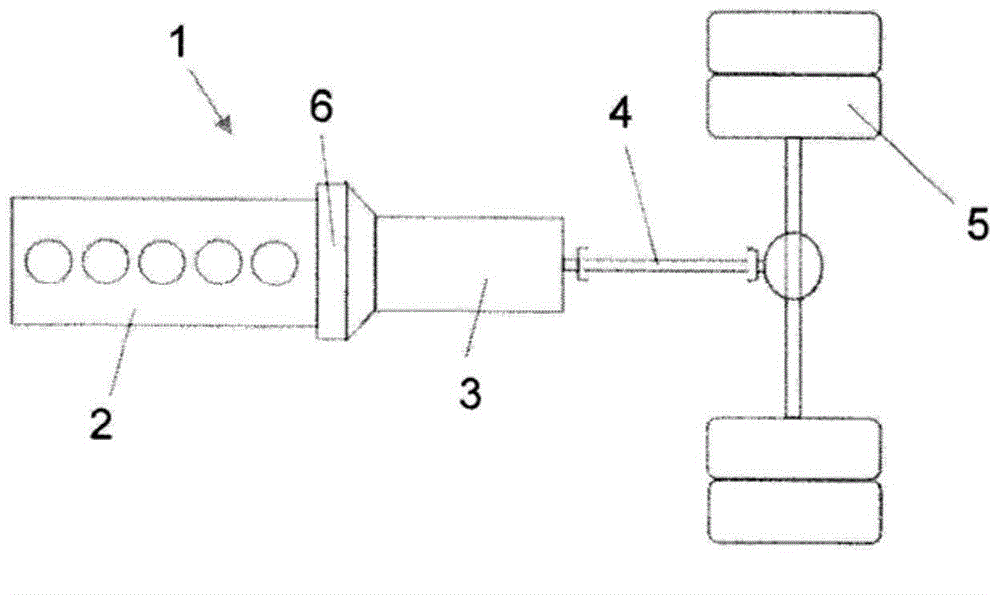

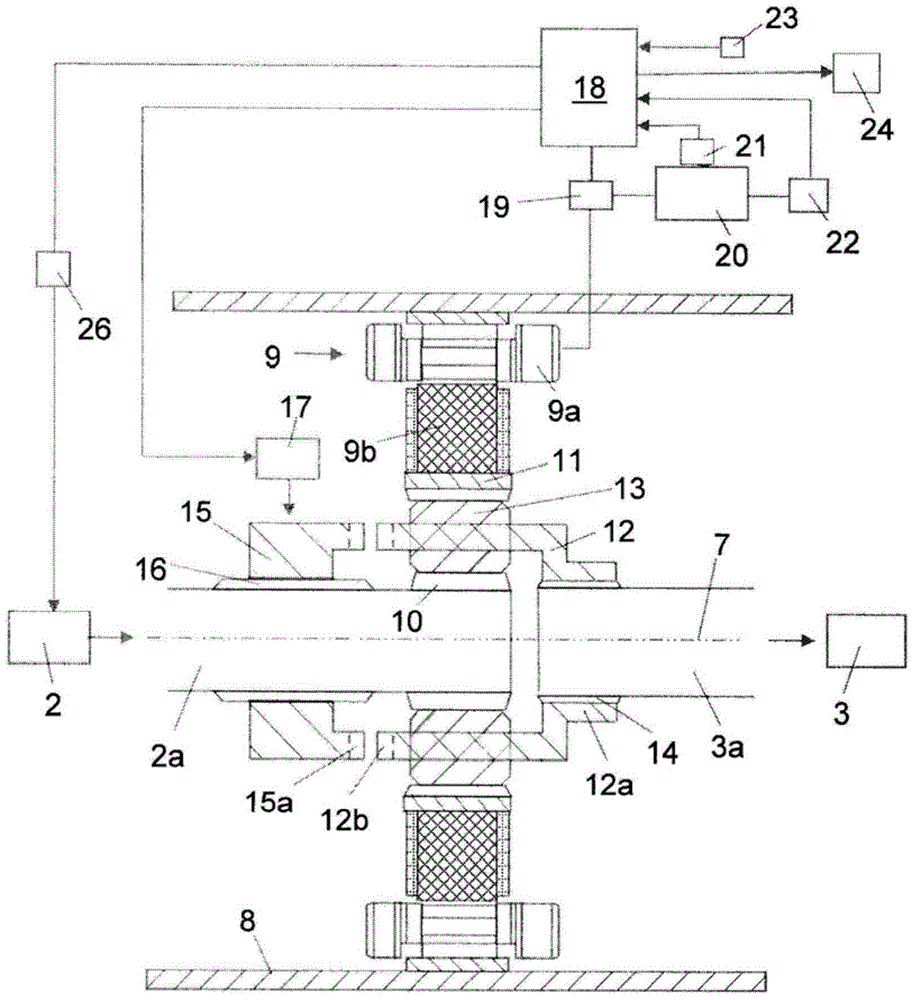

[0022] figure 1 A drive train for a heavy-duty vehicle 1 is shown. The drive train includes a combustion engine 2 , a gearbox 3 , a plurality of drive shafts 4 and drive wheels 5 . Between the combustion engine 2 and the gearbox 3 , the drive train comprises an intermediate section 6 . figure 2 The components in the middle part 6 are shown in more detail. In the middle part 6, the combustion engine 2 is provided with an output shaft 2a and the gearbox 3 is provided with an input shaft 3a. The output shaft 2a of the combustion engine is arranged coaxially with respect to the input shaft 3a of the gearbox. The output shaft 2 a of the combustion engine and the input shaft 3 a of the gearbox are arranged rotatably about a common axis of rotation 7 . The middle part 6 comprises a housing 8 enclosing the electric motor 9 and the planetary gear. The electric machine 9 comprises a stator 9a and a rotor 9b in a conventional manner. The stator 9a comprises a stator core attached ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com