Surface-combustion gas burner

A gas burner and surface combustion technology, which is applied to gas fuel burners, burners, combustion methods, etc., can solve the problems of increasing the total cost of the burner and expensive steel fibers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

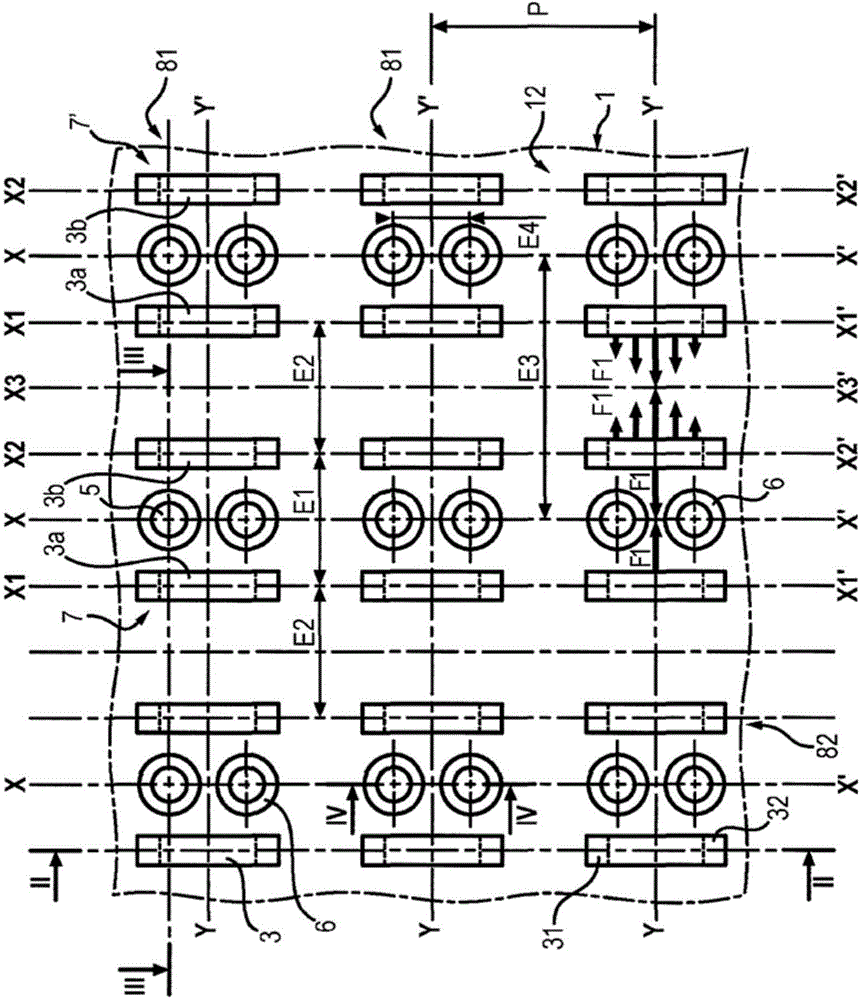

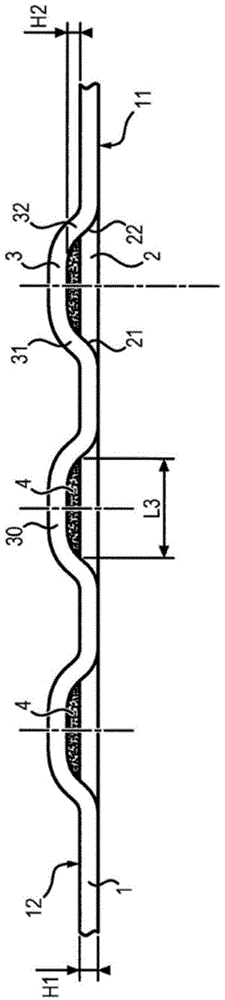

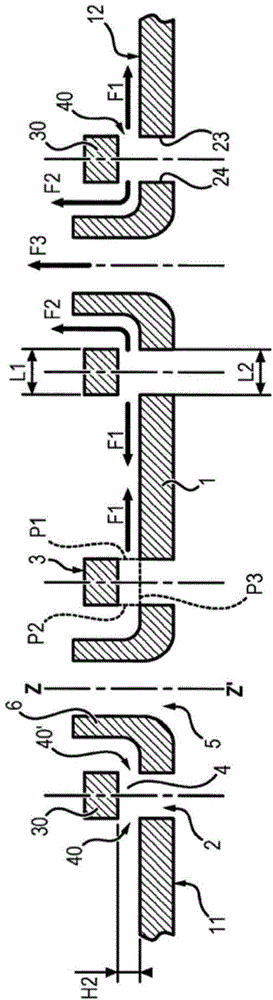

[0048] A first embodiment of a gas burner according to the invention will be referred to Figure 1-4 And is described.

[0049] The burner includes a combustion grid. It is connected to a device (not shown), such as a fan, configured to convey a gas-air mixture under pressure (eg, natural gas and air) into the combustor. The gas mixture passes through the ports and openings of the grid and combustion starts from the outer surface of the combustion grid thanks to an ignition system known to those skilled in the art.

[0050] The combustion grid consists of a sheet (or plate) 1 made of metal, such as stainless steel or of refractory material. The inner and outer surfaces are marked 11 and 12 respectively.

[0051] The sheet 1 is perforated with a series of slits 2 of generally rectangular shape, each slit 2 having two longitudinal edges 23,24.

[0052] Each slot 3 is capped with a bridge 3 or "bridge" which is in one piece (integrated) with the sheet 1 and protrudes from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com