Osmanthus tree trimming and reshaping machine

A technology of sweet-scented osmanthus trees and molding machines, applied in agricultural machinery and tools, cutting tools, cutting equipment, etc., can solve the problems of unsafe branches, irregular shapes, and inability to trim, and achieve the effect of improving safety and regular shapes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

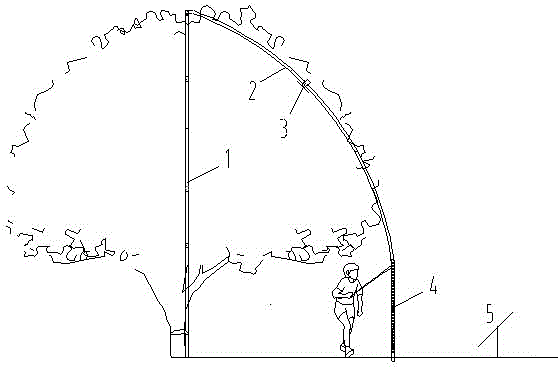

[0012] exist figure 1 The osmanthus tree pruning machine is composed of a fixed rod (1), a guide rail (2), a ground support rod (4), a motor assembly (3), and an observation mirror (5). The fixed rod (1) is fixed on the trunk, and the guide rail ( 2) One end is lapped on the fixed rod (1), the other end is connected to the ground support rod (4), the ground support rod (4) is fixed on the ground, the motor assembly (3) is installed on the guide rail (2), and the observation mirror (5 ) fixed to the ground.

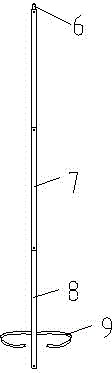

[0013] exist figure 2 The middle fixing rod (1) is composed of the inner fixing rod (8), the outer fixing rod (7) and the support head (6). The number of the inner fixing rod (1) and the outer fixing rod (7) is determined according to the height of the tree. Ensure that the supporting head (6) is higher than the top of the tree, the inner fixing rod (8) is inserted into the outer fixing rod (7) to fix, and the lower end of the fixing rod (1) is bound to the trunk with a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap