A kind of toluene and methanol alkylation catalyst and its preparation method and application

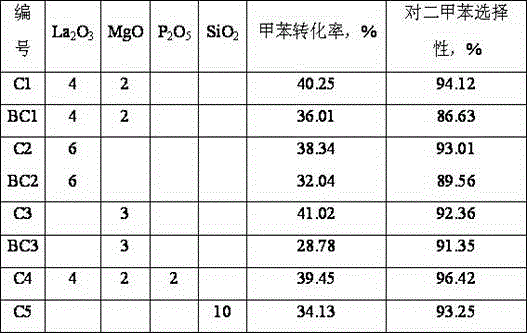

A catalyst and alkylation technology, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve problems such as the reduction of xylene conversion rate, achieve toluene conversion rate and para-xylene selectivity improvement, The effect of increasing acid density and acid content and increasing selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

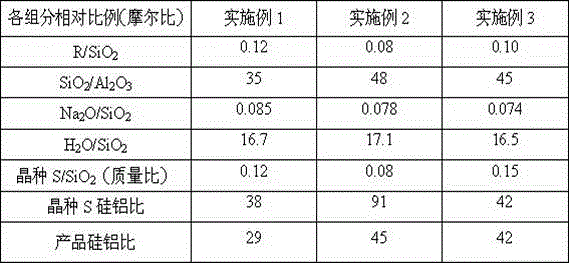

[0035] (1) Weigh sodium hydroxide and sodium aluminate (Al 2 o 3 , 43wt%; Na 2 O, 38wt%) was dissolved in deionized water, and then the templating agent R (12-crown-4, content >97%) was added while stirring at a water bath temperature of 60°C, and after stirring for 0.5 hours, white carbon black was added, After stirring for 1 hour, add seed crystal S, continue stirring for 2 hours, and then move to a closed stainless steel reaction kettle.

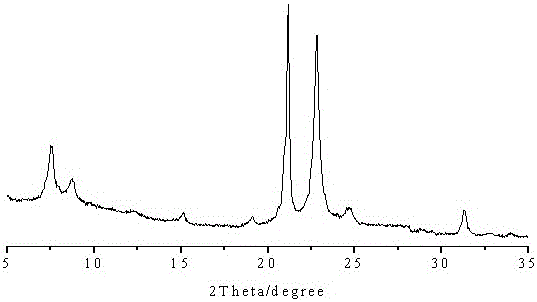

[0036] (2) Crystallized at 160°C for 6 days, the obtained crystallized product was analyzed as ZSM-48 molecular sieve by XRD analysis, the specific raw material ratio and product properties are shown in Table 1.

Embodiment 2

[0038] (1) Same as step (1) of Example 1.

[0039] (2) Crystallized at 158°C for 8 days, the obtained crystallized product was analyzed as ZSM-48 molecular sieve by XRD analysis, the specific raw material ratio and product properties are shown in Table 1.

Embodiment 3

[0041] (1) Same as step (1) of Example 1, the temperature of the water bath is 80°C.

[0042] (2) Crystallize at 160°C for 5 days, and the obtained crystallized product is ZSM-48 molecular sieve by XRD analysis. The specific raw material ratio and product properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com