Unobstructed full-circle sprinkling and stabilized pressure drip-proof micro atomizer and mounting and application method thereof

A non-blocking, micro-sprinkler technology, applied in the direction of spray devices, spray devices, etc., can solve the problems that the bracket cannot achieve full-circle spraying, cannot be atomized, and the structure of the micro-sprinkler is complicated, so as to avoid dripping phenomenon and improve the uniformity of irrigation. The effect of high degree and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings, but the embodiments of the invention are not limited thereto.

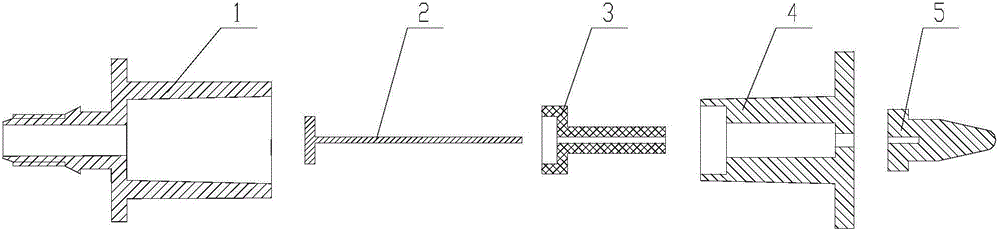

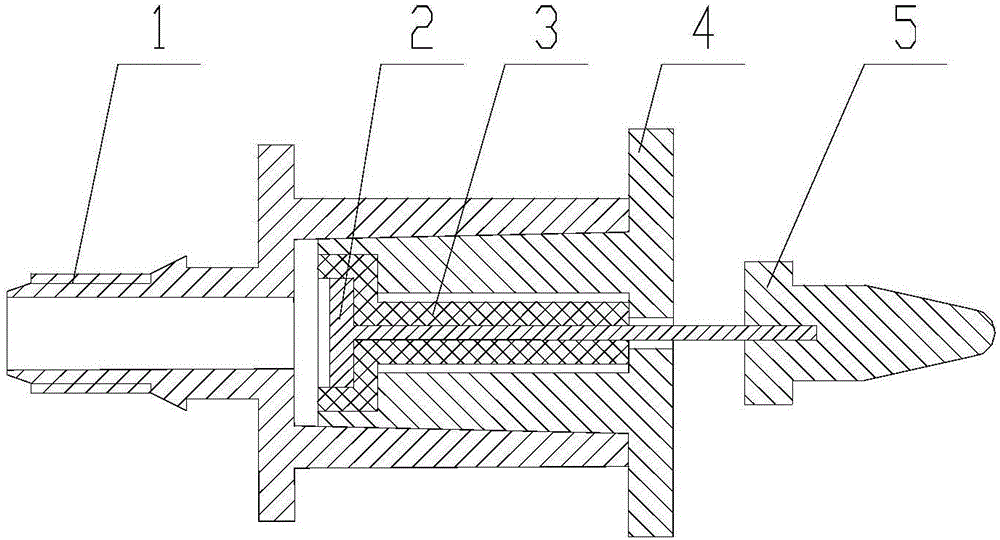

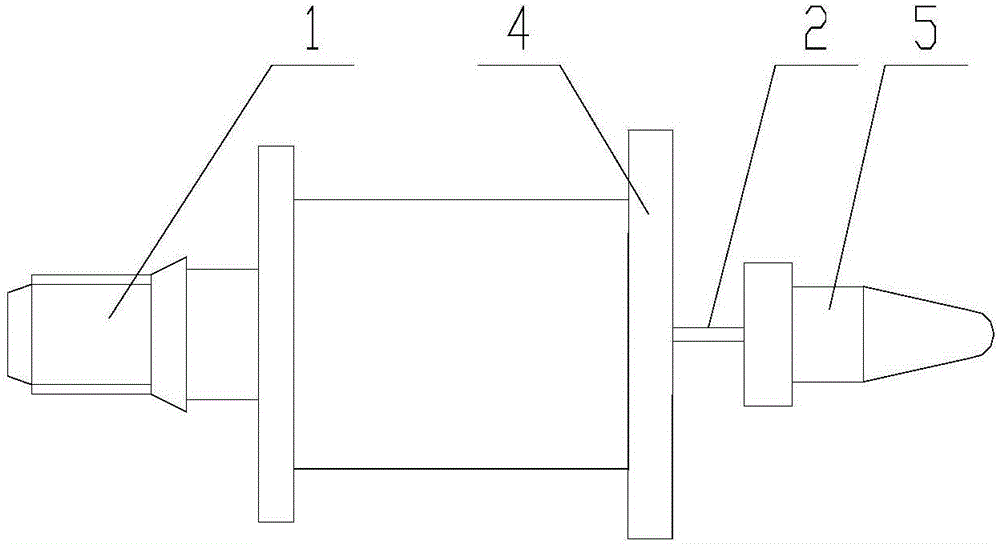

[0029] As shown in the figure, an unobstructed full-circle spraying stabilized pressure anti-drip atomizing micro sprinkler head includes a nozzle cap 1 , a fixed rod 2 , a stabilized pressure anti-drip diaphragm 3 , a nozzle body 4 and a refracting body 5 .

[0030] The inner surface of the nozzle cap 1 has a taper of 1.2:100, the outer surface of the nozzle body 4 has the same taper, and the inner and outer surfaces of the two are closely matched through the taper. The nozzle cap 1 can be connected with the pipeline through a screw thread or an oblique joint.

[0031] The fixed rod 2 passes through the middle hole of the pressure-stabilizing anti-drip diaphragm 3, and the voltage-stabilizing anti-drip diaphragm 3 has elasticity and is tightly pressed on the fixed rod 2 in a sealed s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com