Ultrasonic-pneumatic nozzle

A spray head and ultrasonic technology, applied in spray devices, liquid spray devices, and devices for capturing or killing insects, etc., can solve the problems of low effective utilization of drugs, threats to people's health, and excessive drug residues, and achieve the benefits of drugs and Nutrient absorption, improving droplet atomization, reducing drug waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

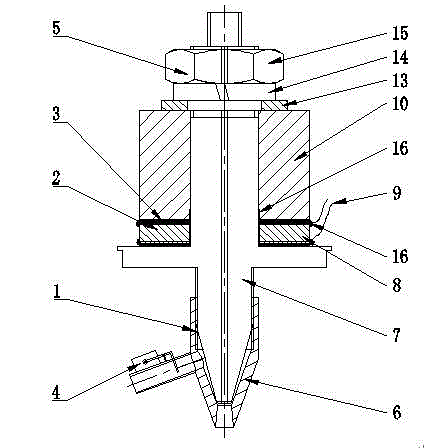

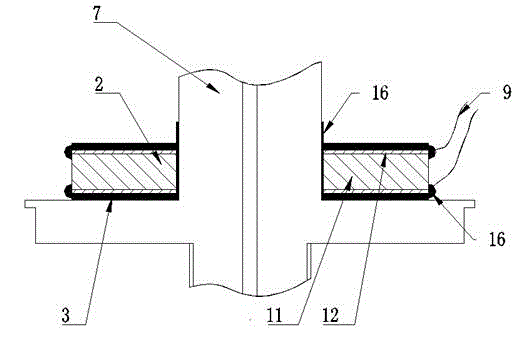

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0021] Such as figure 1 , figure 2 As shown, an ultrasonic-pneumatic spray head includes a spray rod with a small liquid flow channel processed on the axis, an ultrasonic generating device, and a nozzle for the spray head. On the spray rod, the ultrasonic generating device is located on the side of the supporting device away from the nozzle, and the ultrasonic generating device is pressed and fixed on the supporting device by a fastening device. There are piezoelectric wafers, back seats and wires, the wires are connected to the piezoelectric wafers, the wires are insulated wires, and the exposed parts are sealed with insulating glue after being introduced into the piezoelectric wafers. The back seat is located at one end of the piezoelectric chip and is in contact with the fastening device. The piezoelectric chip is provided with a piezoelectric cer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com