Air floatation bearing and air floatation high-speed high-photoelectric main shaft

An air bearing and bearing technology, which is applied to bearings, shafts and bearings, large fixed members, etc., can solve problems such as insufficient radial load, and achieve the effects of improving radial load, improving machining accuracy and improving machining efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

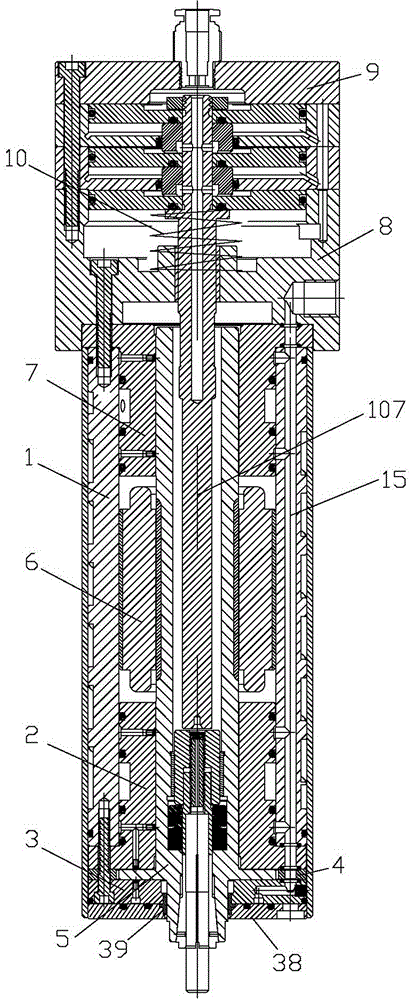

[0047] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

[0048] Before the specific introduction, let’s explain the front and back mentioned in the technical scheme and implementation of the present application, take the end of the rotor mounting chuck as the front end, and the end far away from the rotor mounting chuck as the rear end, and refer to the front and rear .

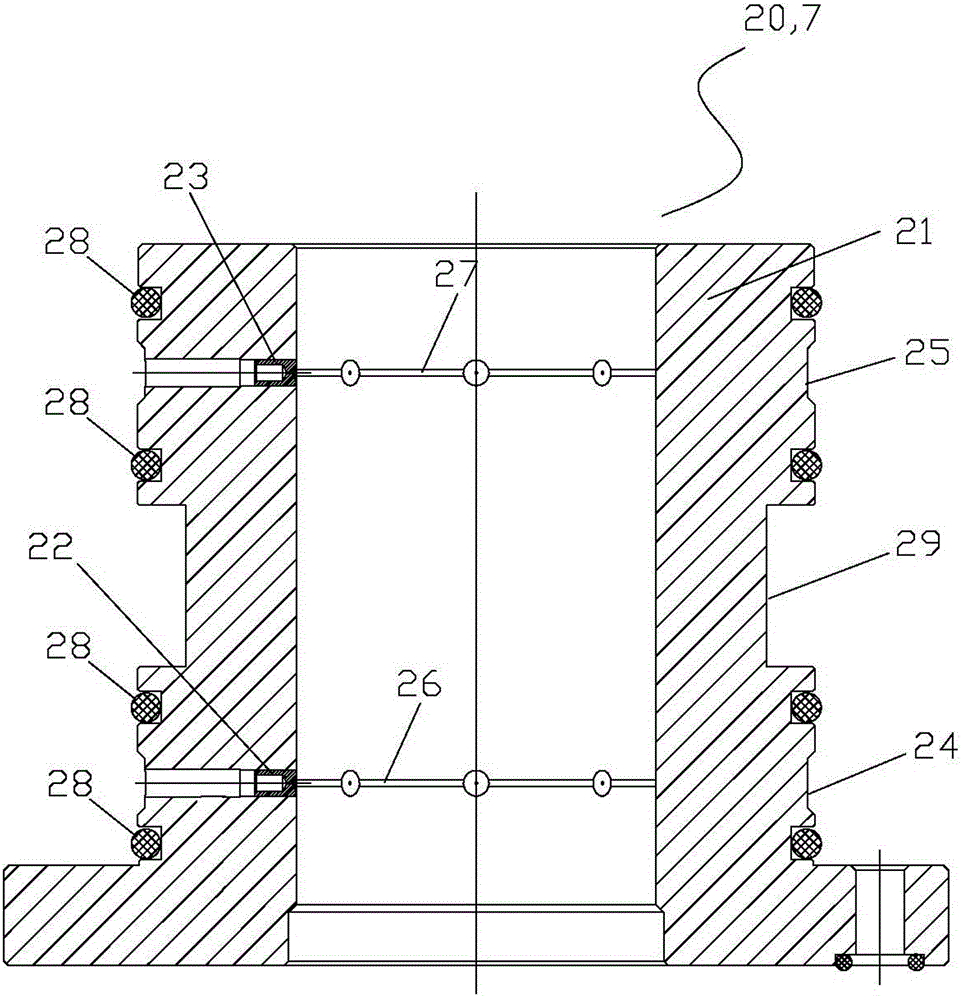

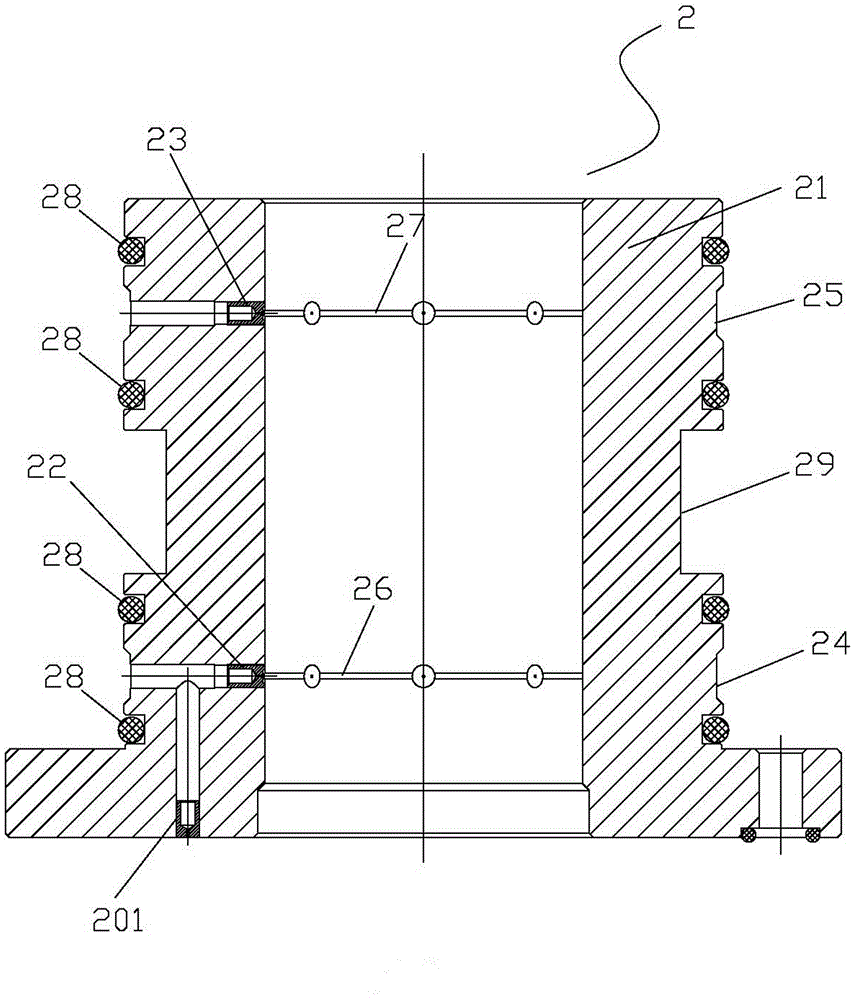

[0049] like figure 1 As shown, an air bearing 20 includes a cylindrical bearing body 21 with no bottom at both ends. The front and rear radial nozzles 22 and rear radial nozzles 23 are respectively equipped at the front and rear ends of the bearing body 21. The front diameter The radial nozzle 22 and the rear end radial nozzle 23 are arranged radially and form inner and outer ends, the outer end is close to the outer wall, and the inner end is close to the inner wall;

[0050] The outer walls of the front and rear ends of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com