Polyethylene wax with inner and outer lubrication performances

A polyethylene wax and polyvinyl chloride technology, applied in the field of polyethylene wax, can solve the problems of poor light and thermal stability, small branching degree, discoloration, etc., and achieve the effect of enhancing mechanical properties and increasing surface gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

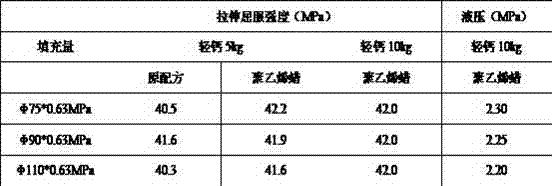

Image

Examples

Embodiment 1

[0020] In the embodiment of the present invention, a polyethylene wax with both internal and external lubrication includes the following raw materials: 95 kg of polyvinyl chloride, 3 kg of calcium-zinc composite stabilizer, 1.5 kg of acrylate copolymer, 3.5 kg of chlorinated polyethylene, and 0.2 kg of lubricant kg, rutile titanium dioxide 1.5kg. Weigh polyvinyl chloride, calcium-zinc composite stabilizer, acrylate copolymer, chlorinated polyethylene, lubricant, rutile titanium dioxide, mix them, stir and heat at 50°C for 200 minutes; the stirring speed is 1000r / min.

Embodiment 2

[0022] In the embodiment of the present invention, a polyethylene wax with both internal and external lubrication includes the following raw materials: 105 kg of polyvinyl chloride, 4.5 kg of calcium-zinc composite stabilizer, 2.5 kg of acrylate copolymer, 4.5 kg of chlorinated polyethylene, lubricant 0.5kg, rutile titanium dioxide 2.5kg. Weigh polyvinyl chloride, calcium-zinc composite stabilizer, acrylate copolymer, chlorinated polyethylene, lubricant, rutile titanium dioxide, mix them, stir and heat at 120°C for 50 minutes; the stirring speed is 100r / min.

Embodiment 3

[0024] In the embodiment of the present invention, a polyethylene wax with both internal and external lubrication includes the following raw materials: 98 kg of polyvinyl chloride, 3.5 kg of calcium-zinc composite stabilizer, 1.8 kg of acrylate copolymer, 3.8 kg of chlorinated polyethylene, lubricant 0.25kg, rutile titanium dioxide 1.8kg. Weigh polyvinyl chloride, calcium-zinc composite stabilizer, acrylate copolymer, chlorinated polyethylene, lubricant, rutile titanium dioxide, mix them, stir and heat at 70°C for 80 minutes; the stirring speed is 200r / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com