High-gloss self-lubricating high polymer material special for cosmetic brush packaging

A polymer material, high gloss technology, applied in the field of polymer materials, can solve the problems of uneven dynamic friction, unstable static friction, easy wear of products, etc., to ensure surface activity, improve molding conditions, and reduce the effect of material specific gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

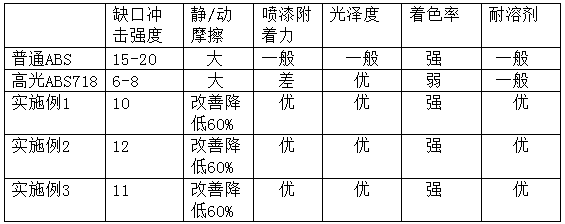

Examples

Embodiment 1

[0021] A special high-gloss self-lubricating polymer material for cosmetic pencil packaging, comprising the following components in parts by weight: 75 parts of acrylonitrile-butadiene-styrene plastic, 5 parts of polymethyl methacrylate, liquid dispersant 0.1 part, 1 part compatibilizer, 0.1 part solid dispersant, 5 parts lubricant.

[0022] The acrylonitrile-butadiene-styrene plastic used in it uses plate-grade materials to provide mechanical support and alleviate the mechanical decline caused by multi-components. The specific grade is ABS747S; polymethyl methacrylate is used to improve the gloss of the material , the specific grade is CM205.

[0023] Specifically, the liquid dispersant is silicone oil, and the specific brand is Dow Corning silicone oil OFX-5043.

[0024] Specifically, the solid dispersant is waxy ethylene bisstearic acid amide, and the specific brand is Kao BFF.

[0025] Furthermore, the use of liquid dispersants and solid dispersants to ensure surface act...

Embodiment 2

[0032] The difference from Example 1 is that this example provides a special high-gloss self-lubricating polymer material for cosmetic pencil packaging, which includes the following components in parts by weight: 83 parts of acrylonitrile-butadiene-styrene plastic , 11 parts of polymethyl methacrylate, 1.1 parts of liquid dispersant, 2 parts of compatibilizer, 2.1 parts of solid dispersant, and 7.4 parts of lubricant.

[0033] More specifically, the silicone powder and polytetrafluoroethylene are 4.1 parts by weight of silicone powder and 3.3 parts of polytetrafluoroethylene.

Embodiment 3

[0035] The difference from Example 1 is that this example provides a special high-gloss self-lubricating polymer material for cosmetic pencil packaging, which includes the following components in parts by weight: 95 parts of acrylonitrile-butadiene-styrene plastic , 15 parts of polymethyl methacrylate, 2 parts of liquid dispersant, 5 parts of compatibilizer, 5 parts of solid dispersant, 10 parts of lubricant.

[0036] More specifically, the silicone powder and polytetrafluoroethylene are 5 parts by weight of silicone powder and 5 parts of polytetrafluoroethylene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com