Marking method based on controllable distance indication and 3D (three-dimensional) laser marking machine

A laser marking machine, 3D technology, applied in typewriters, laser welding equipment, printing and other directions, can solve the problems of distortion of marking patterns, lack of positioning structure, and difficulty for technicians to accurately place and adjust the height of marking objects. Achieve the effect of improving focusing efficiency, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] This embodiment corresponds to the above-mentioned second and third principles, that is, the situation of using two reflective mirrors to deflect light, see Figure 5 to Figure 10 , the laser marking machine of the present invention comprises a cabinet 9, a reference plate 7 arranged on the cabinet 9, a control unit 8 arranged on the cabinet 9, a lifting frame 6 vertically arranged on the reference plate 7, a marking head 5, and a lift A rotating handle 61 is provided on the top of the frame 6, and the marking head 5 is arranged on the elevating frame 6. The height of the marking head 5 can be adjusted by rotating the rotating handle 61. This is a method of manual adjustment. In the present invention, the control unit 8 can also Automatically adjust the lifting frame 6. When the height difference of the marking object is large (beyond the focal length range of laser marking), the position of the marking head 5 can be adjusted manually or automatically, so that the markin...

Embodiment 2

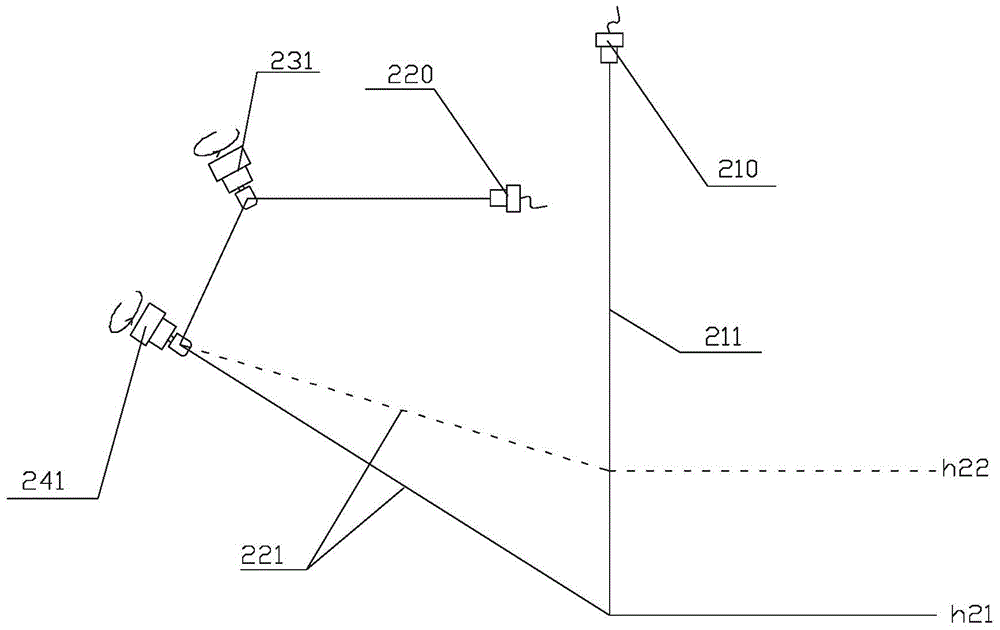

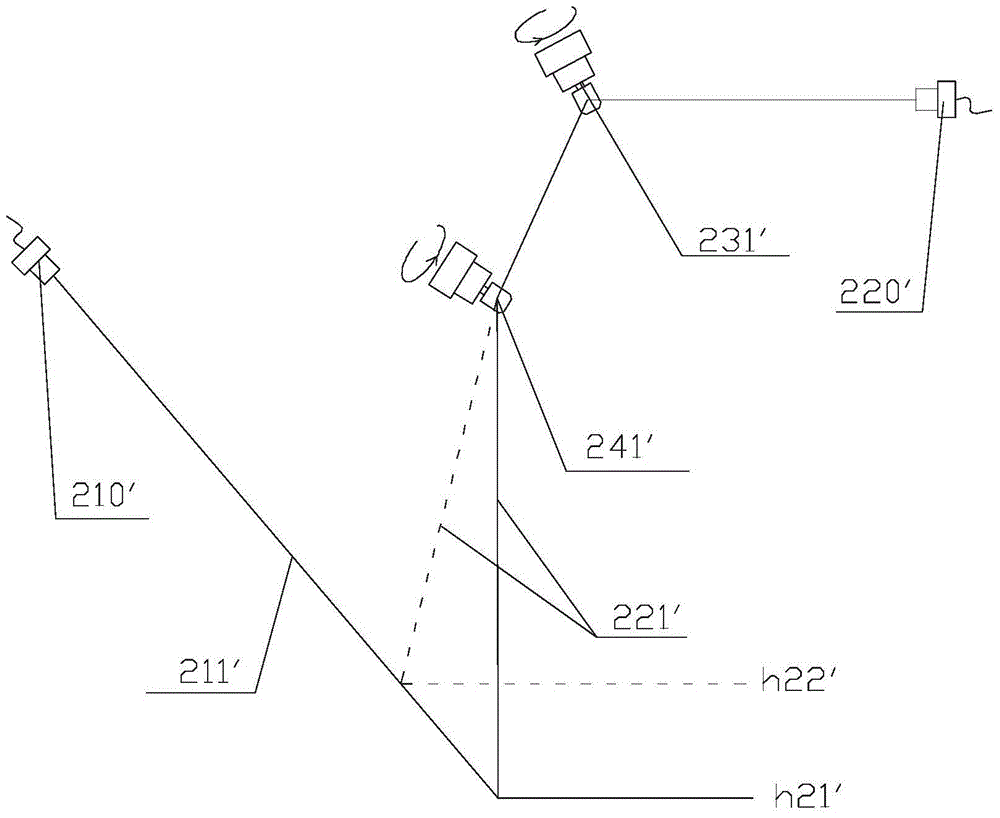

[0086] See attached Figure 11 , the laser in this embodiment, the second visible light beam 321 emitted by the second visible light indicator 320, the reflection device (including the first mirror 332 driven and controlled by the first motor 331 and the second mirror 332 driven and controlled by the second motor 341 Reflector 342) is the same as Embodiment 1, the difference is that the front housing of this embodiment is also provided with an adjusting device (the third reflector 352 driven and controlled by the third motor 351), and the first visible light indicator 310 emits The first visible light beam 311 is emitted, and the first visible light beam 311 encounters the third reflective mirror 352 during transmission, and the first visible light beam 311 intersects with the second visible light beam 321 after being reflected by the third reflective mirror 352, and the intersection point is For the optimal working point of laser marking, the function of the added adjustment ...

Embodiment 3

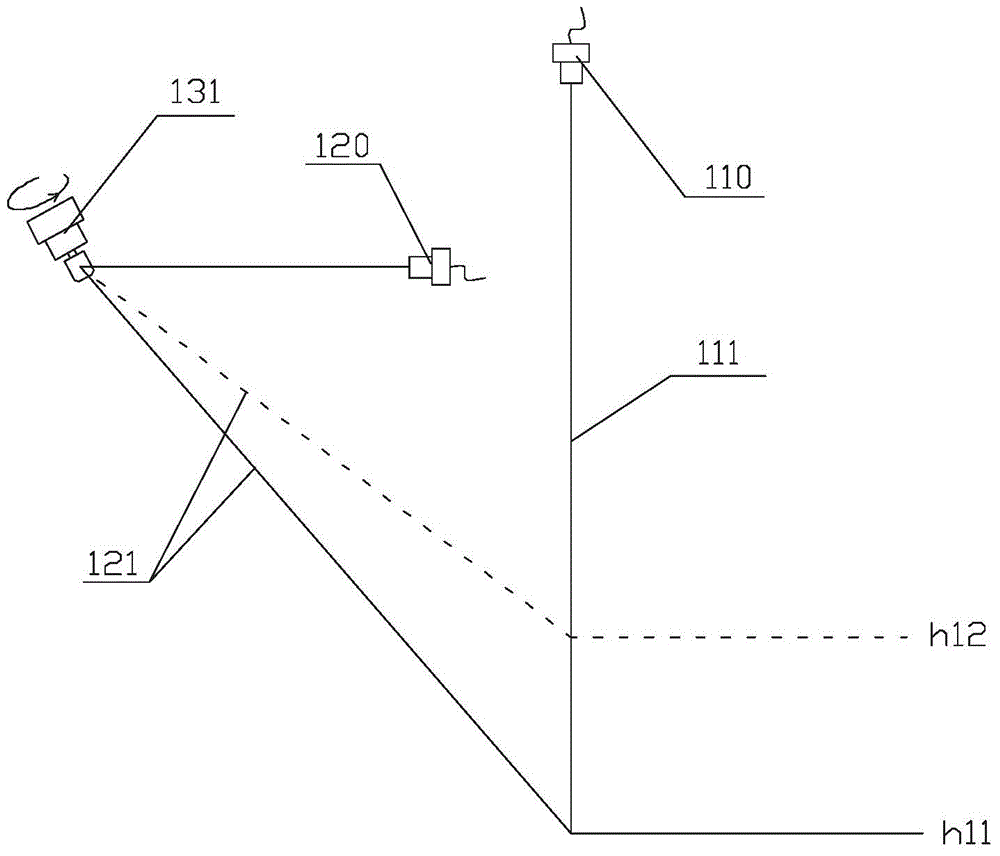

[0088] See attached Figure 12 , what this embodiment applies is the first principle, that is, the second visible light beam 121 is only reflected once, the reflection device in this embodiment is different from Embodiment 1, and the reflection device in this embodiment is driven by the first motor deflection of the first mirror 132 .

[0089]The first visible light indicator 110 in this embodiment and the first visible light indicator 210 in Embodiment 1 can be mounted on the front case in the same manner, and the first visible light emitted by the first visible light indicator 110 in this embodiment The light beam 111 is a downward fixed light, and the first reflector 132 controls the deflection of the second visible light beam 121 through the first motor 131 to achieve the effect of changing the height of the intersection point; the structure of this embodiment is simple and the cost is low. A reflective lens, but the requirements for installation are relatively high, sinc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com