Numerically controlled edge milling machine and automatic switching method thereof

A technology of automatic switching and CNC milling, applied in milling machine equipment, details of milling machine equipment, metal processing mechanical parts, etc., can solve the problem of low precision of secondary drilling of CNC edge milling machine for circuit boards, etc. The effect of small space and simple switching process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

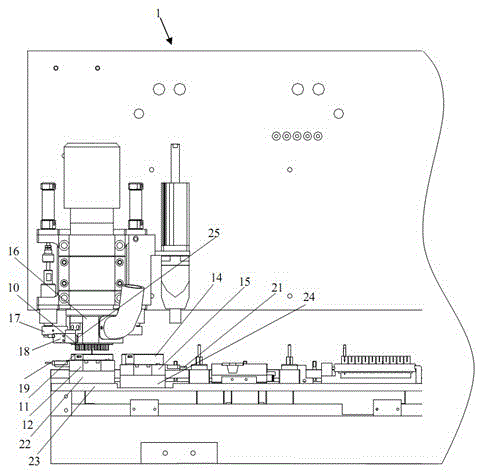

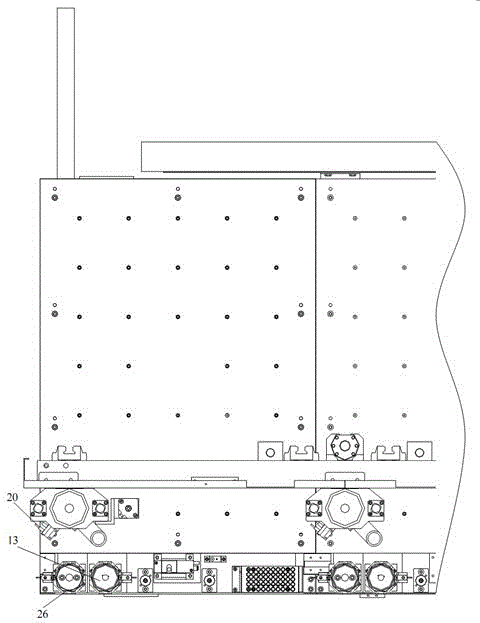

[0020] Such as Figure 1-2 As shown, the CNC edge milling machine 1 of the present invention comprises a hair brush 10, a hair brush cover 11 fixed together with the hair brush 10, a rotating disk 12 in the hair brush cover 11 for placing the hair brush cover 11, a presser foot 13, and a presser foot The presser foot cover 14 with the feet 13 fixed together, the turntable 15 in the presser foot cover for placing the presser foot cover 14, the main shaft 16 that can move up and down, the chip suction cover 17 that can move up and down with the main shaft 16, and can act on the brush The cylinder 18 on the cover 11 and the presser foot cover 14, the induction switch 19 for sensing the relative displacement of the brush cover 11 and the main shaft 16, the magnetic switch 20 for sensing the normal position of the cylinder 18, and the switch of the presser foot cover 14 A successful proximity switch 21, a rotating disc fixing seat 22 in the brush cover for supporting the rotating d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com