Single whetstone sharpening device for kitchen knife processing

A knife sharpening device and grinding stone technology, which is applied in the direction of grinding driving device, grinding/polishing safety device, metal processing equipment, etc., can solve the problems of not very high quality, uneven sharpening force, blunt kitchen knife blade, etc. , to achieve the effect of improving the sharpening effect, improving the clamping effect and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

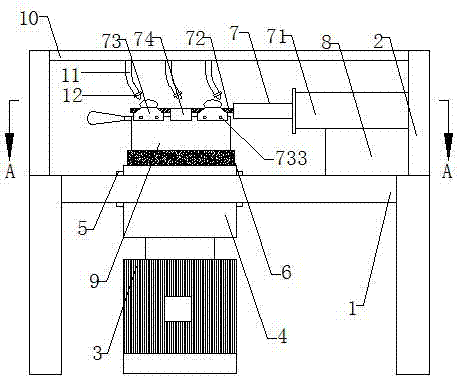

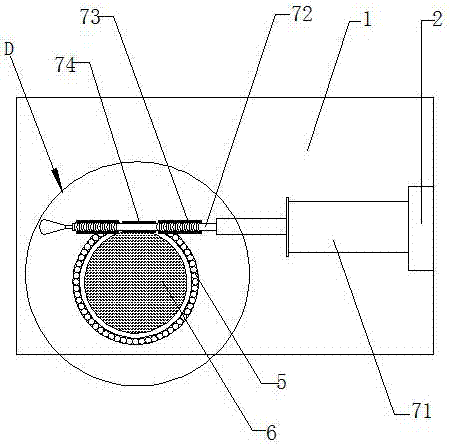

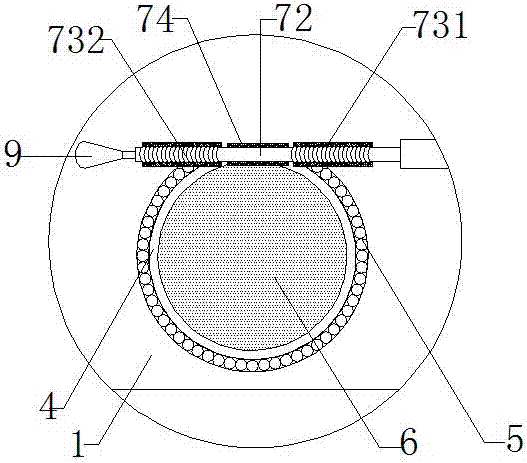

[0019] Refer to attached Figure 1-3 The shown single whetstone sharpening device for processing kitchen knives includes an operating platform 1, side supports 2 are vertically arranged on both sides of the upper end surface of the operating platform 1, and a water spray mechanism is set up in the middle of the side supports 2. The water mechanism includes a water pipe 10 and three hoses 11 that are sealed and connected below the water pipe 10. The three hoses 11 are equidistantly arranged in the middle of the water pipe 10 and downward, and at the end of each of the hoses 11 The spray head 12 is installed, and the hose 11 can be bent in any direction to ensure that there is no dead angle for spraying on the surface of the knife body. The water pipe 10 is erected between the two side supports 2 and is supplied with water by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com