Positioning device for wood board drilling

A technology of positioning device and plank, which is applied in the direction of drilling machines, wood processing equipment, manufacturing tools, etc., can solve the problem of lack of fixing devices, etc., and achieve the effect of clamping stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below by means of specific embodiments:

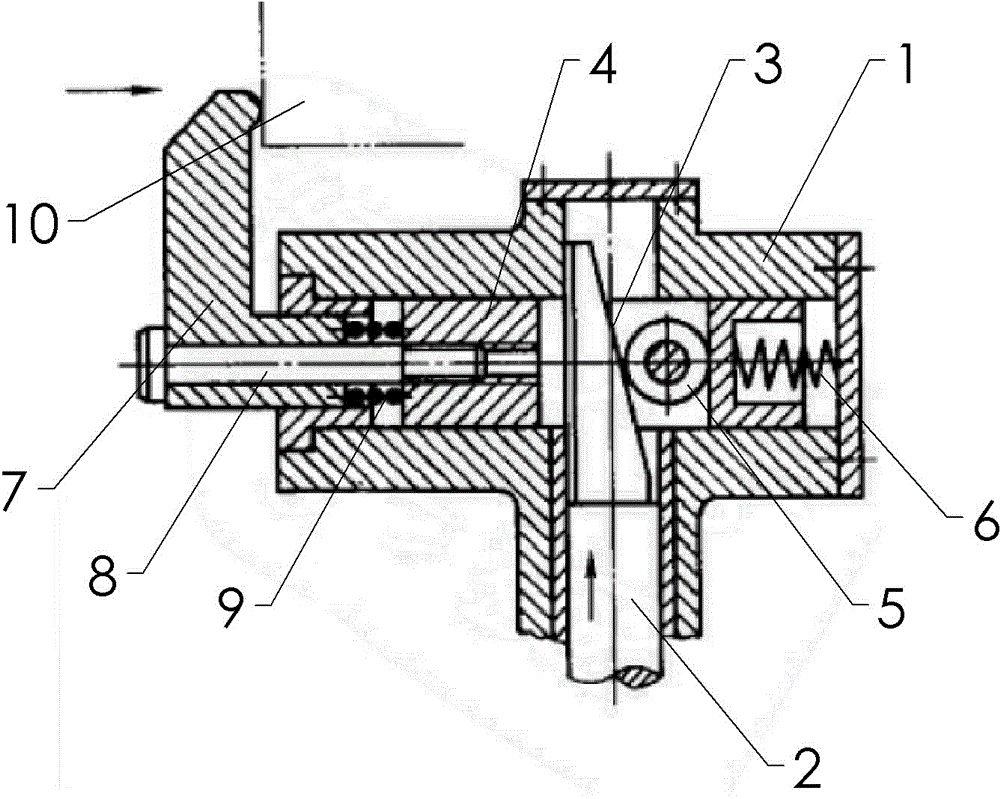

[0012] The reference signs in the drawings of the description include: clamp body 1, drive rod 2, inclined plane 3, tension rod 4, roller 5, spring 6, jaw 7, bolt 8, compression spring 9, workpiece 10.

[0013] The embodiment is basically as attached figure 1 As shown: the clamp body is fixed below the workpiece, and the interior of the clamp body is provided with intersecting horizontal holes and vertical holes, and its tail end is sealed by a plate. In the double-force cylinder shown in the figure, the piston rod of the double-force cylinder extends vertically upwards and is connected with the lower end of the driving rod through a coupling.

[0014] The upper end of the drive rod is provided with a slope, and is located at the intersection of the horizontal hole and the vertical hole. The horizontal hole is axially slidably connected with a tension rod. The middle sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com