Static exchanger for production of extruded polystyrene foam plates

A technology of extruded polystyrene and exchanger, which is applied in the field of extruded board manufacturing equipment, and can solve problems such as temperature imbalance of No. 2 single-screw main engine, raw material heat, unfavorable board remaining process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

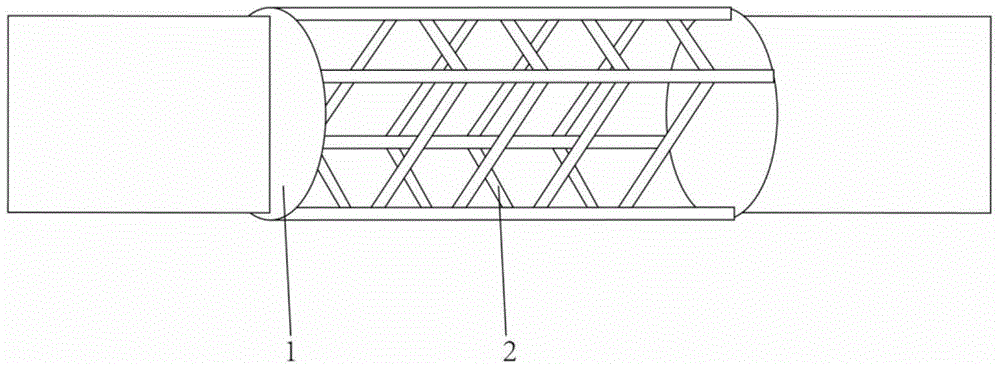

[0012] Such as figure 1 Shown: a static exchanger for the production of extruded polystyrene foam boards, including a protective cover 1 and a rectifying grid 2, the static exchanger is installed in the No. 2 single-screw main screw and mold of the extruded polystyrene foam board production line Between them, the inlet end of the static exchanger is connected to the No. 2 single-screw main engine, and the outlet end of the static exchanger is connected to the mould. The rectifying grids 1 are arranged in the protective cover 2, and the rectifying grids 1 are arranged in a spiral shape. Disturbing rods are arranged inside the rectifying grid 1 to better change the flow direction of raw materials.

[0013] It should be pointed out that those skilled in the art can make some improvements and modifications without departing from the principle of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com