Antifake digital printing quality control system

A control system and digital printing technology, applied in the direction of printing, printing machines, general parts of printing machinery, etc., can solve problems such as image deformation, comparison error, and quality control accuracy, and achieve low manufacturing cost, easy use, The effect of ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

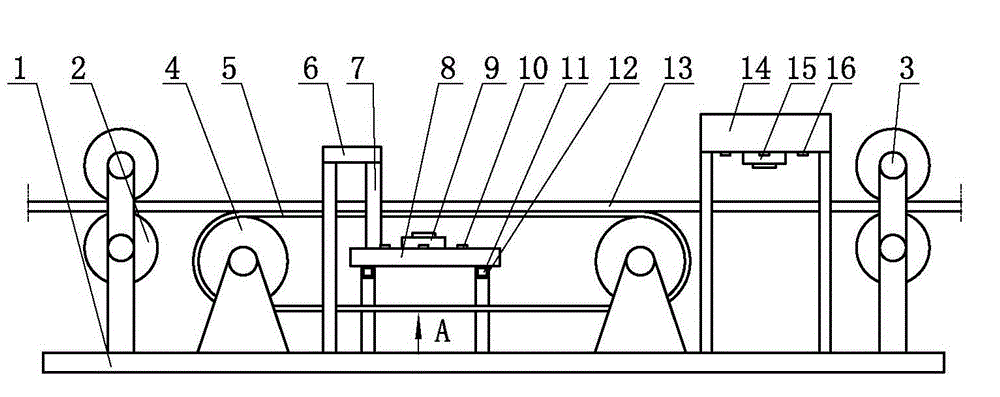

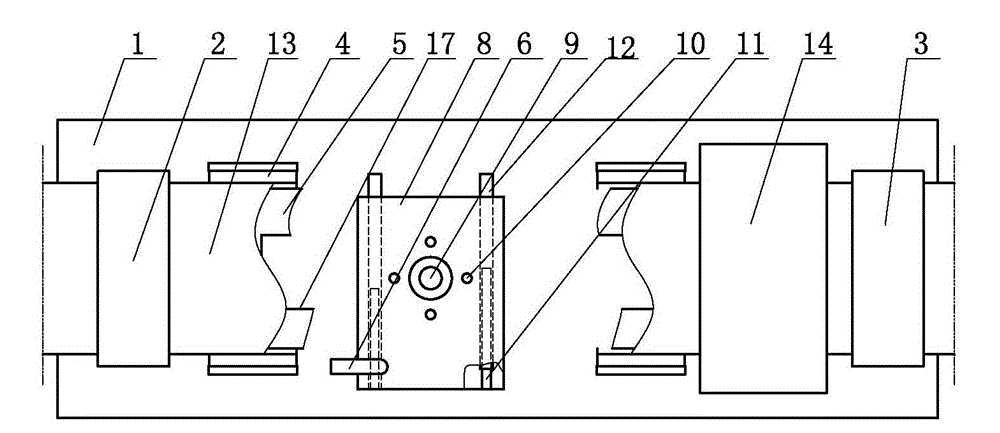

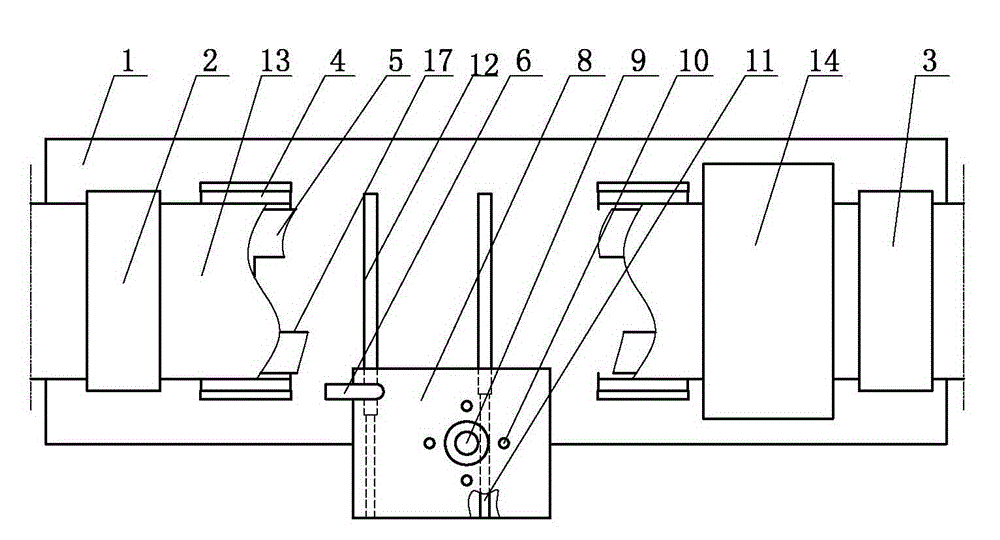

[0009] Anti-counterfeiting digital printing quality control system, such as figure 1 As shown, it includes base 1, on which paper feed roller 2 and paper discharge roller 3 are installed, paper feed roller 2 and paper discharge roller 3 are fixedly installed on both ends of base 1 respectively, between paper feed roller 2 and paper discharge roller 3 Printing paper 13 is arranged between them, a linear array CCD camera 15 is arranged on the upper part of the printing paper 13, an area array CCD camera 9 is arranged on the lower part of the printing paper 13, an idler roller 4 is arranged between the paper feed roller 2 and the paper outlet roller 3, and an idler roller 4 is arranged on the idler roller 4. Roller belt 5, idler belt 5 is at the bottom of printing paper 13, as Figure 4 Shown, offer through window 17 on the idler belt 5. The printing paper 13 enters from the paper feed roller 2 on the left side of the direction shown in the figure, passes through the supporting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com