Supporting caster

A caster and foot support technology is applied in the field of multi-purpose support casters, which can solve the problems of easy shaking, low bearing weight and easy damage of universal casters, and achieve the effect of adjustable height, large bearing weight and stable bearing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

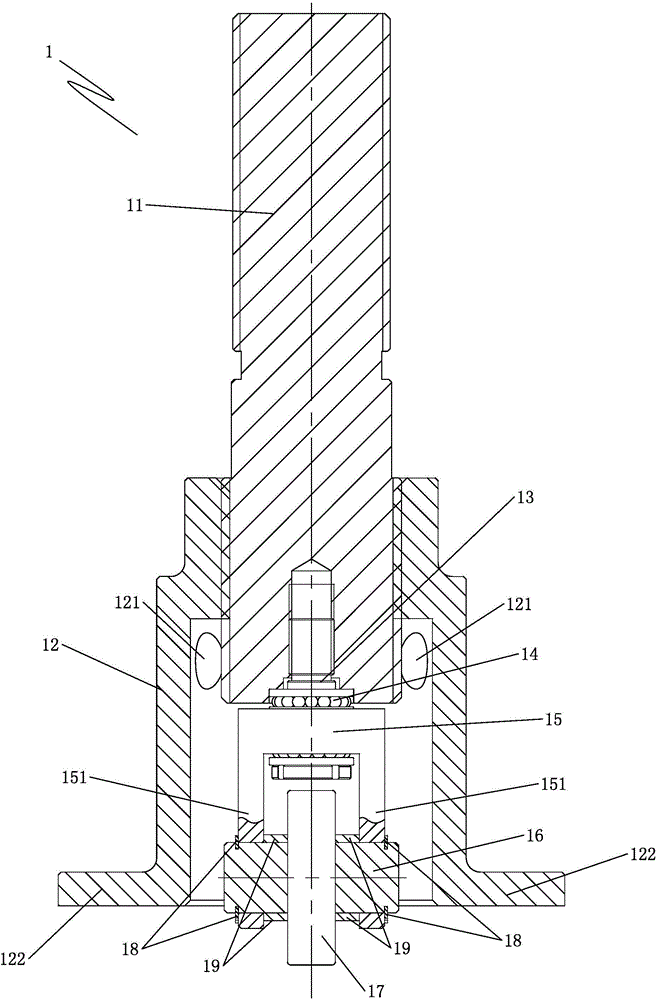

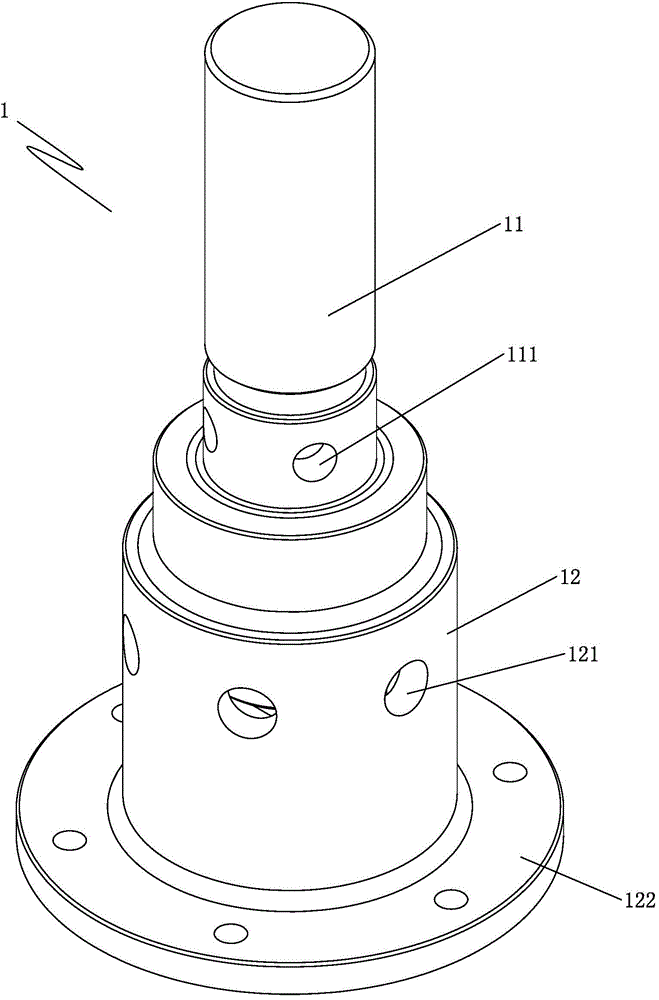

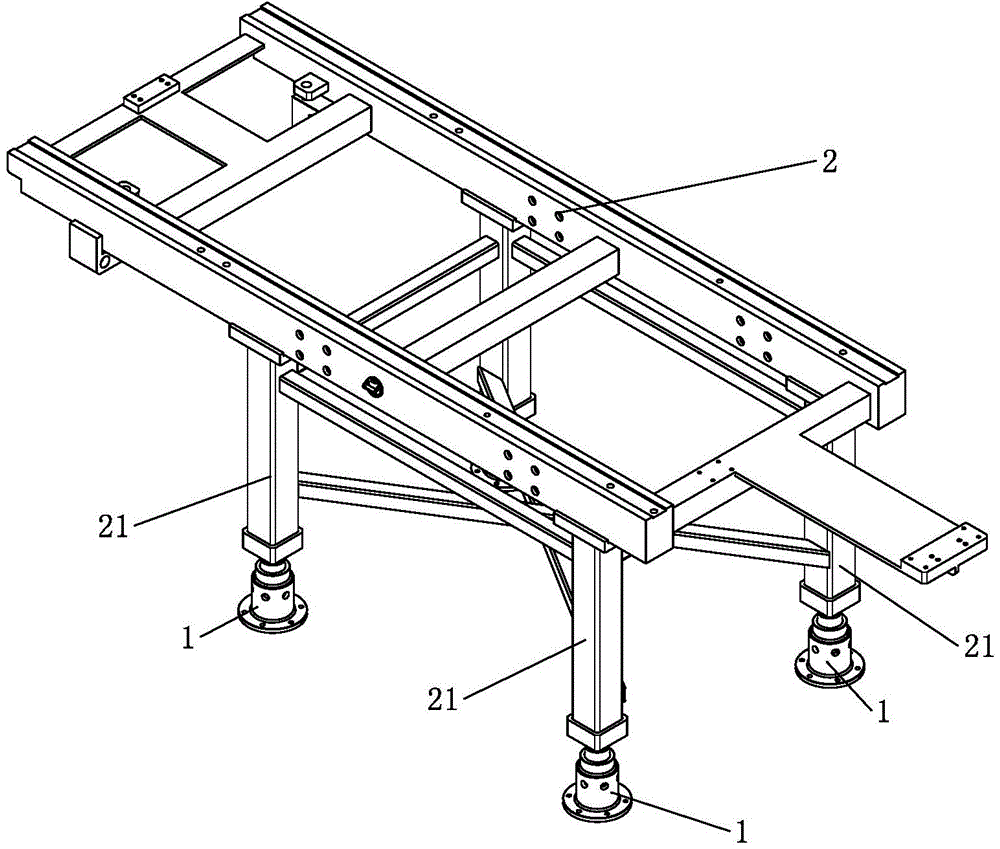

[0016] Such as Figures 1 to 3 As shown, the supporting caster 1 of the present invention is designed for the mold loading and unloading platform 2 of a large extrusion molding machine, which has a large load-bearing capacity and needs to be moved and adjusted in height. Its structure includes: caster mounting screw 11 , Movable foot support cover 12, first roller shaft 13, thrust ball bearing 14, castor frame 15, second roller shaft 16 and deep groove ball bearing 17. The specific structure is as follows:

[0017] The outer peripheral wall of the lower part of the caster mounting screw 11 is provided with external threads, and its upper part is installed on the supporting feet of the application equipment, such as being installed on the supporting feet 21 of the mold loading and unloading table 2, such as image 3 shown. Due to the large bearing pressure, in order to use external tools to adjust the rotation of the caster mounting screw 11, the middle and upper parts of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com