Balance shaft assembly

A technology for balancing shafts and assemblies, applied in the field of vehicles and engineering, can solve the problems of insufficient assembly weight to meet market supply demand, large number of product parts, and difficult processing, and achieve compact structure, simplified structure, and changed structural characteristics. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

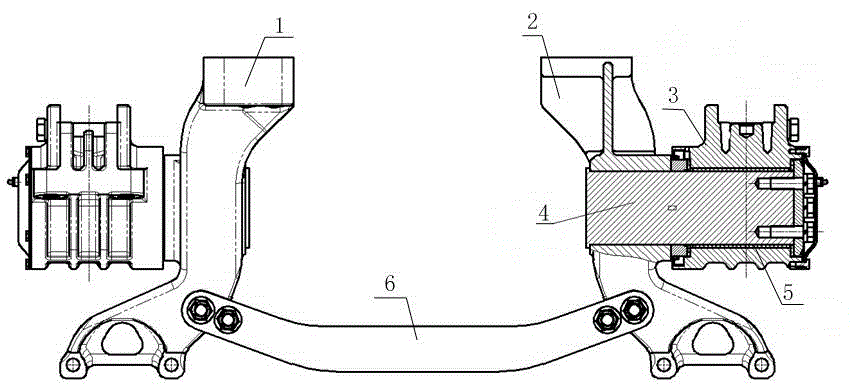

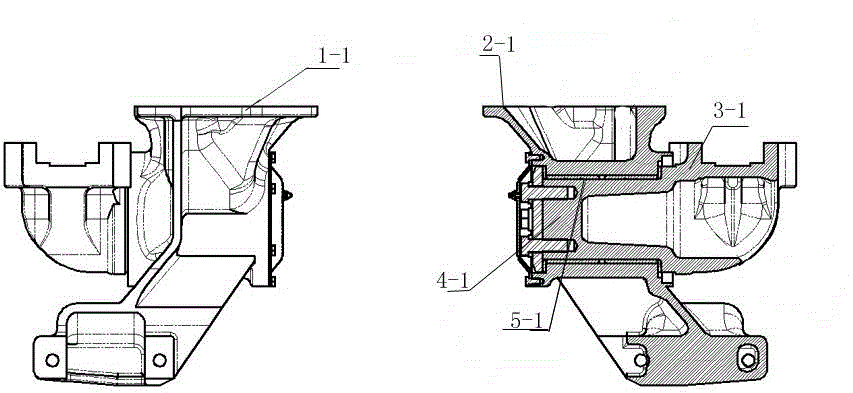

[0014] Such as figure 2 shown.

[0015] A balance shaft assembly, including two brackets 1-1, 2-1 connected to the vehicle frame, the two brackets 1-1, 2-1 are set independently, and are respectively provided with bearing hubs 3 through bushings 5-1 -1, wherein the bearing hub 3-1 and the half shaft 4-1 are of an integral structure.

[0016] In the assembly, the bushing 5-1 transitions between the brackets 1-1, 2-1 connected to the vehicle frame and the bearing hub 3-1 and adopts a sliding fit connection.

[0017] In the installation method of the present invention, the brackets 1-1 and 2-1 are used as the matrix, and the bushing 5-1 is press-fitted into the brackets 1-1 and 2-1 connected to the frame, and then the bearing hub 3-1 is directly Assemble in place, add lubricating grease after assembly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com