Non-leakage guide groove device

A material guide trough, no leakage technology, applied in transportation and packaging, conveyor objects and other directions, can solve the problems of complex structure, high cost, difficult maintenance of skateboards, etc., to achieve low maintenance, long service life, good dust reduction effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

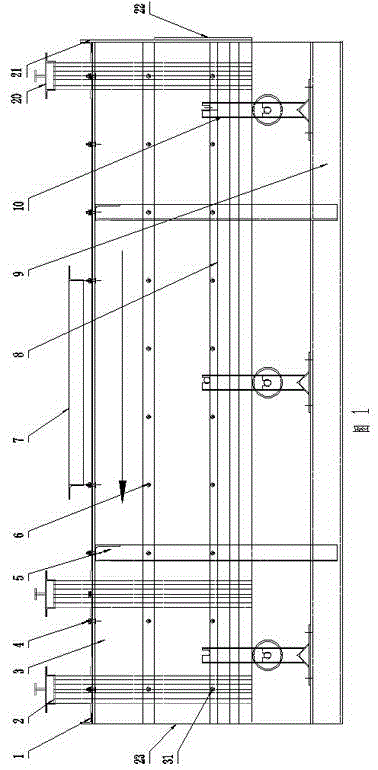

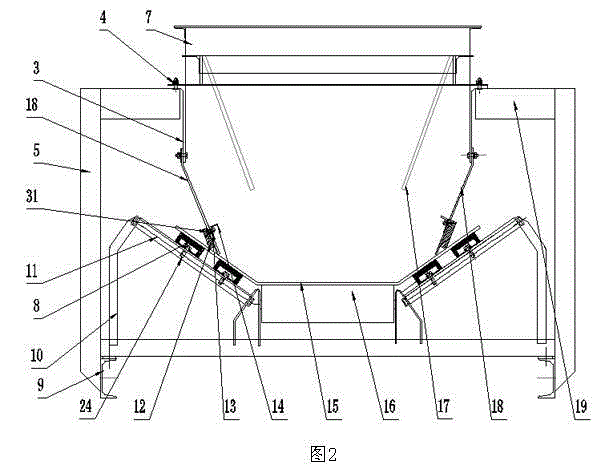

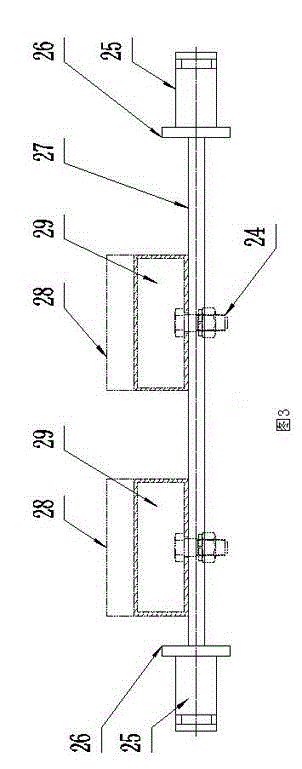

Image

Examples

Embodiment Construction

[0008] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0009] The non-leakage guide trough device of the present invention includes a column 5, a beam 3, an upper cover 1, a groove corner support plate 11, an upper dust-sealed slide plate 12, a material inlet 7, a bottom slide plate 8, a material inlet 7, and a deflector 17, etc. , the upright column 5 is installed on the conveyor frame 9, supports the girder 3 through the upright bracket 19, and its connection mode is welding. The upper cover 1 of the material guide trough is installed on the girder 3 and connected by the upper cover connecting screw 4. The lower side of the girder 3 is connected with the upper dust sealing slide plate connecting plate 18 with the dust sealing plate connecting screw 6, and the upper dust sealing slide plate 12 passes through the upper dust sealing slide plate The connecting bolt 13 is connected with the lower part of the connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com