Car guide rail support

A car guide rail and guide rail technology, applied in elevators, transportation and packaging, etc., can solve the problems of insufficient stability and strength, inconvenient on-site installation, high production cost, etc., achieve simple structure, reduce installation and manufacturing costs, and facilitate use and installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

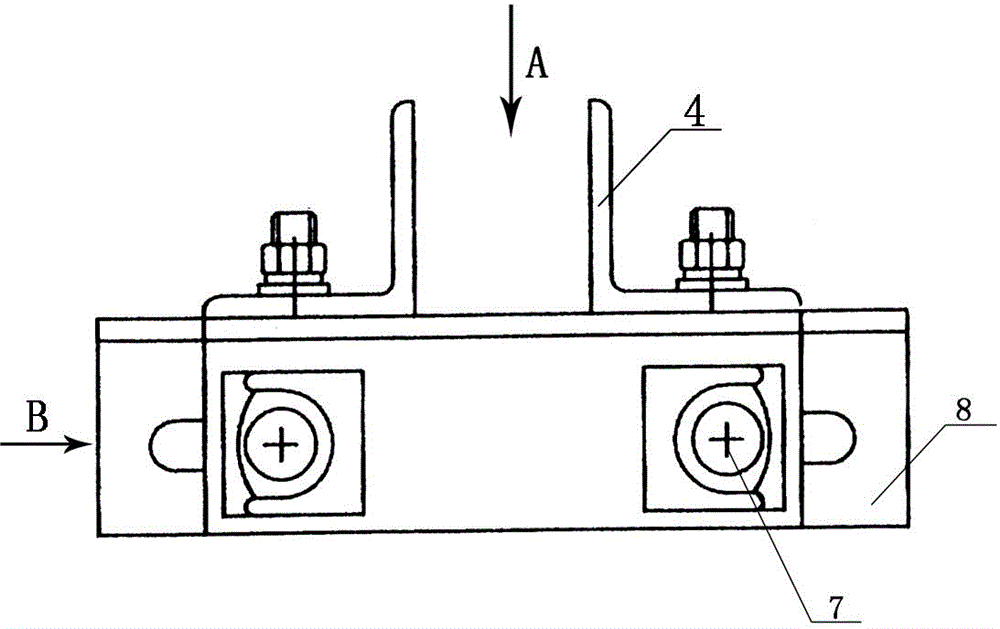

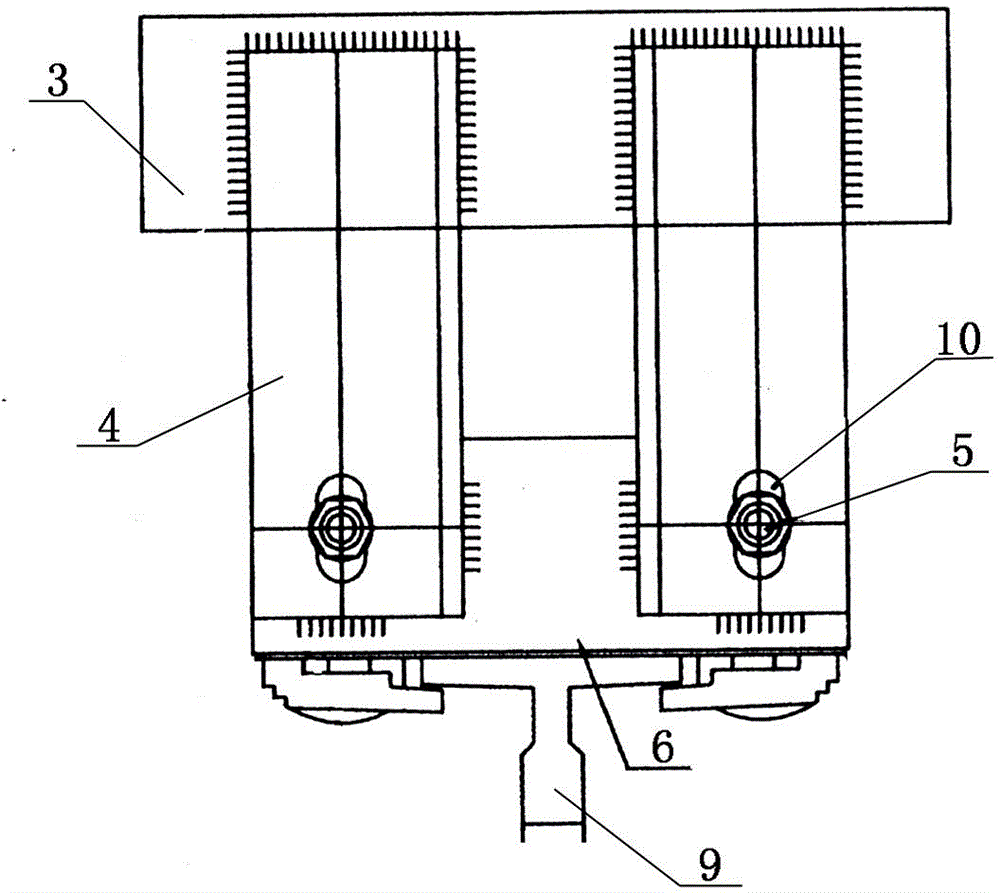

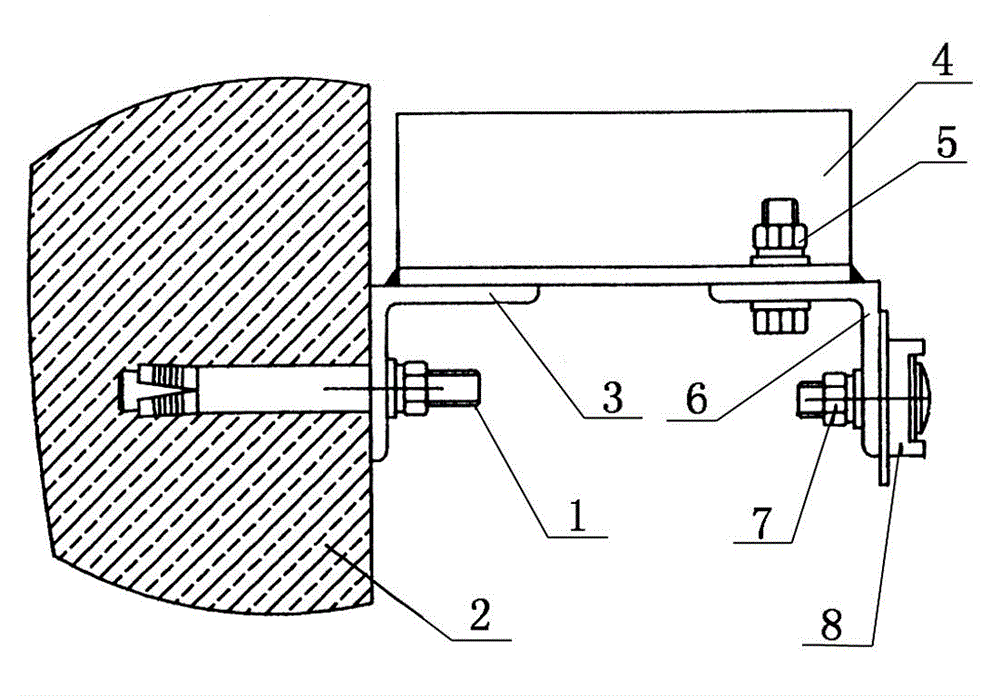

[0010] The present invention will be described in detail below in conjunction with accompanying drawing: Figure 1-3 As shown, a car guide rail bracket according to the present invention includes a wall connecting frame 3 made of angle irons fixed on the wall 2 with expansion screws 1, and the wall connecting frame 3 is There are at least two adjusting frames 4 made of angle irons and perpendicular to the wall by welding; bolts and nuts 5 or a horizontal guide rail connecting frame composed of angle irons are connected with bolts and nuts 5 below the adjusting frames 4 6. A car guide rail 9 is installed and fixed on the guide rail connecting frame 6 through at least bolts, nuts, washers 7 and guide rail fixing plates 8 .

[0011] As shown in the figure, two adjusting frames 4 of the present invention are arranged in parallel between the wall connecting frame 3 and the guide rail connecting frame 6 and are respectively welded together. The adjusting frame 4 is provided with an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com