Colored conductive concrete and preparation method thereof

A conductive concrete and color technology, applied in the field of building materials, can solve problems such as dimness and aesthetic requirements of a single color, and achieve the effects of simple operation, improved conductivity and color rendering performance, and high cost performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

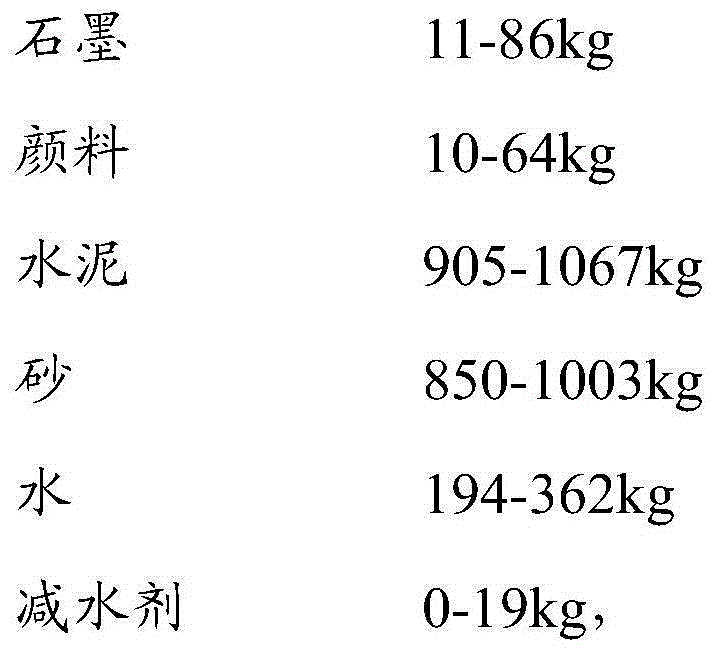

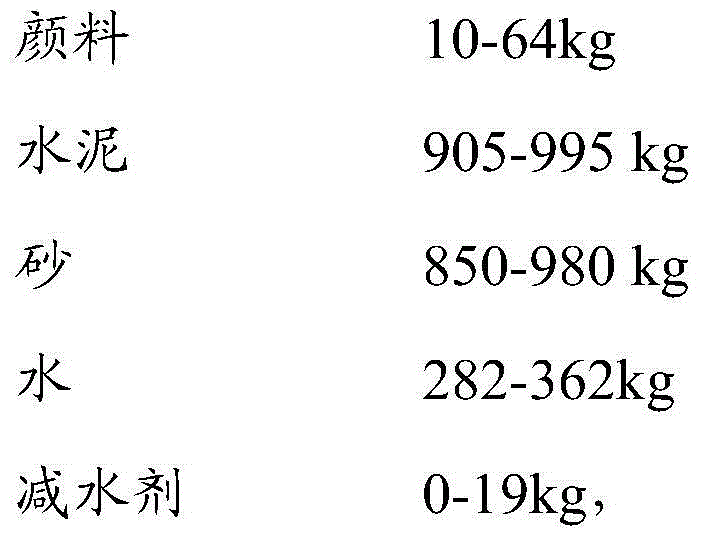

[0039] Embodiment 1-12 is the colored conductive concrete of the present invention, in terms of per cubic meter of colored conductive concrete, including the following raw materials (Table 1):

[0040] Table 1

[0041]

[0042] The gray-sand ratio of the above-mentioned colored conductive concrete is 1:1.

[0043] The preparation method of above-mentioned colored conductive concrete comprises the steps:

[0044] After the graphite, pigment and sand are mixed, the cement and water are gradually added to mix, and the water reducer is added or not, mixed, and after forming and curing processes, the colored conductive concrete is obtained.

[0045] After curing for 28 days, the performance test results of the above-mentioned colored conductive concrete are shown in Table 2:

[0046] Table 2

[0047]

[0048] It can be seen from Table 1 and Table 2 that: under the same amount of pigment, as the amount of graphite increases, its electrical conductivity gradually improves, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com