A straight line glazing mechanism

The technology of straight-line glazing and glazing knife is applied in the field of ceramic production, which can solve the problems of the inability to improve the grade of ceramic products, the thin glaze in the middle and the thick glaze on both sides, and the low precision of glazing. Smooth surface and wide adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be described in detail below in conjunction with specific embodiments.

[0017] The present invention relates to a linear glaze pouring mechanism, which is used in conjunction with a glaze cylinder for storing glaze, wherein the glaze cylinder is provided with a stirring device and a glaze pump, and the glaze pump introduces the glaze into the linear glaze pouring mechanism through a pipeline , and set a receiving trough under the glaze opening of the linear glazing mechanism, the receiving trough is provided with a discharge port, and the glaze material is introduced into the glaze cylinder through the circulation pipeline to avoid the waste of glaze.

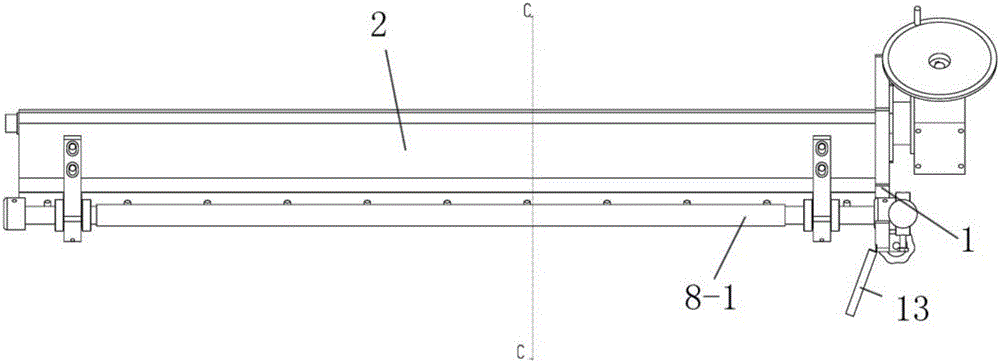

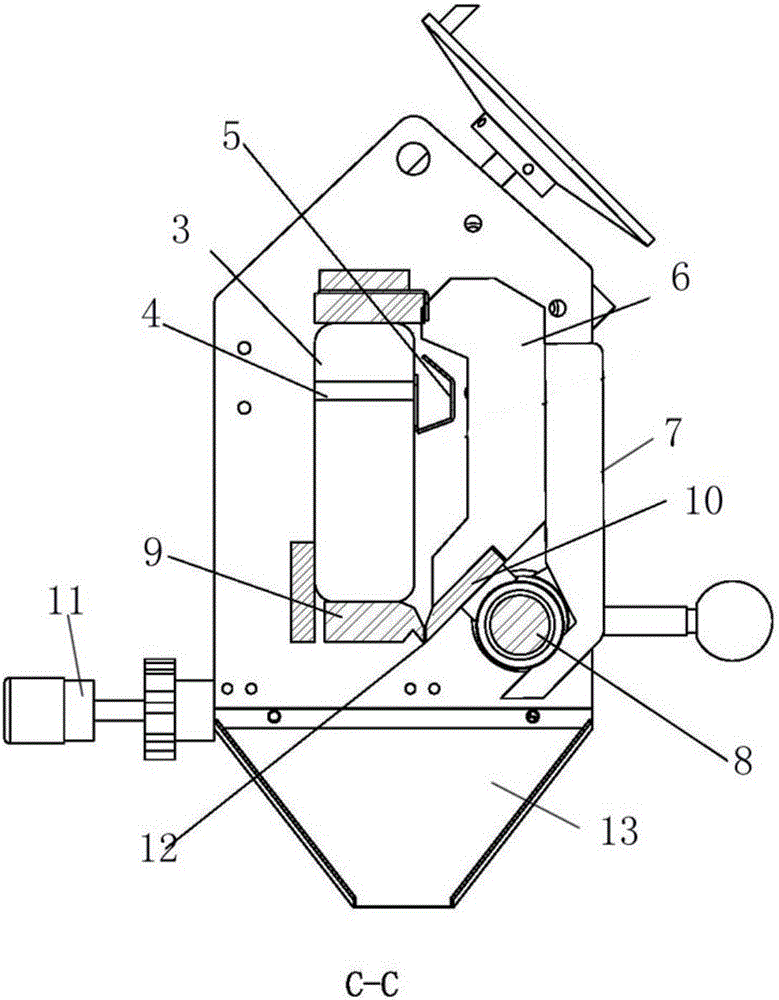

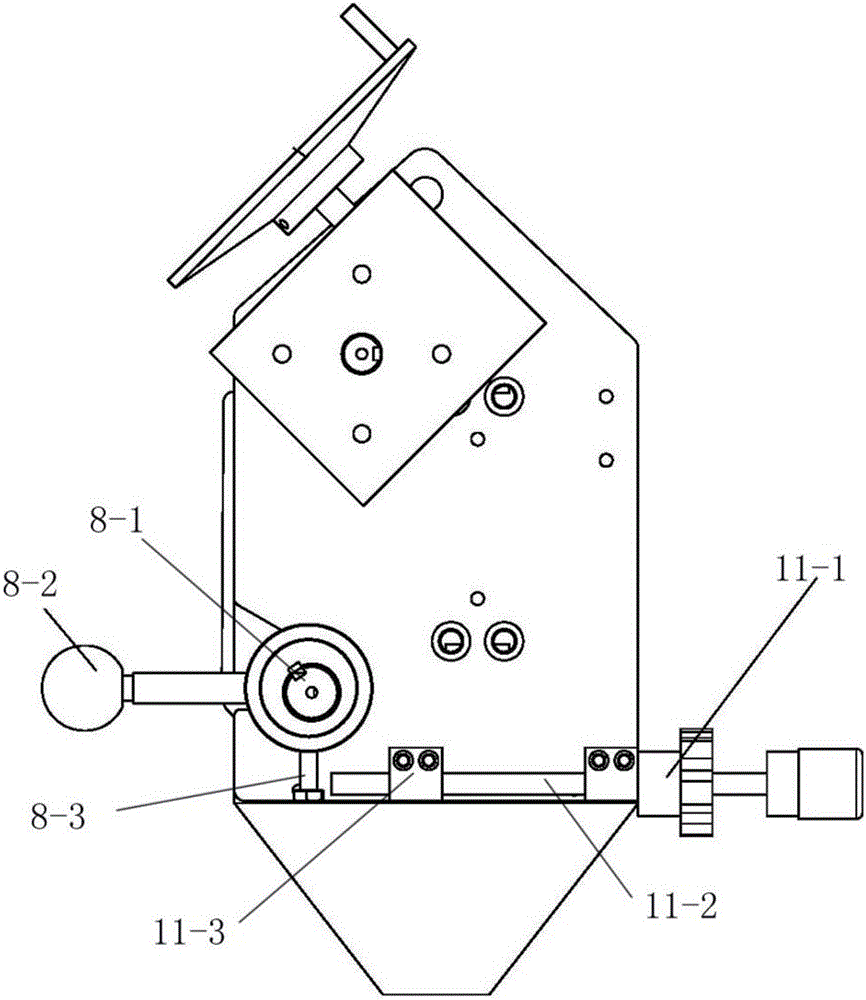

[0018] Such as Figure 1-Figure 3 As shown, the linear glazing mechanism includes a frame 1, a casing 2 and a fixed cavity 3 for storing glazes provided in the frame, a glaze distribution tank 5 corresponding to the glaze supply port 4 of the fixed cavity 3, and a gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com