Method for Optimizing Thickness Adjustment of Adhesive Binding Machines

A technology of thickness adjustment and binding machine, which is applied in the direction of adhesives for binding, book binding, and the compound continuous process of book processing, which can solve the problems of reducing waste pages and obstructions, and achieve the effect of optimizing thickness adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

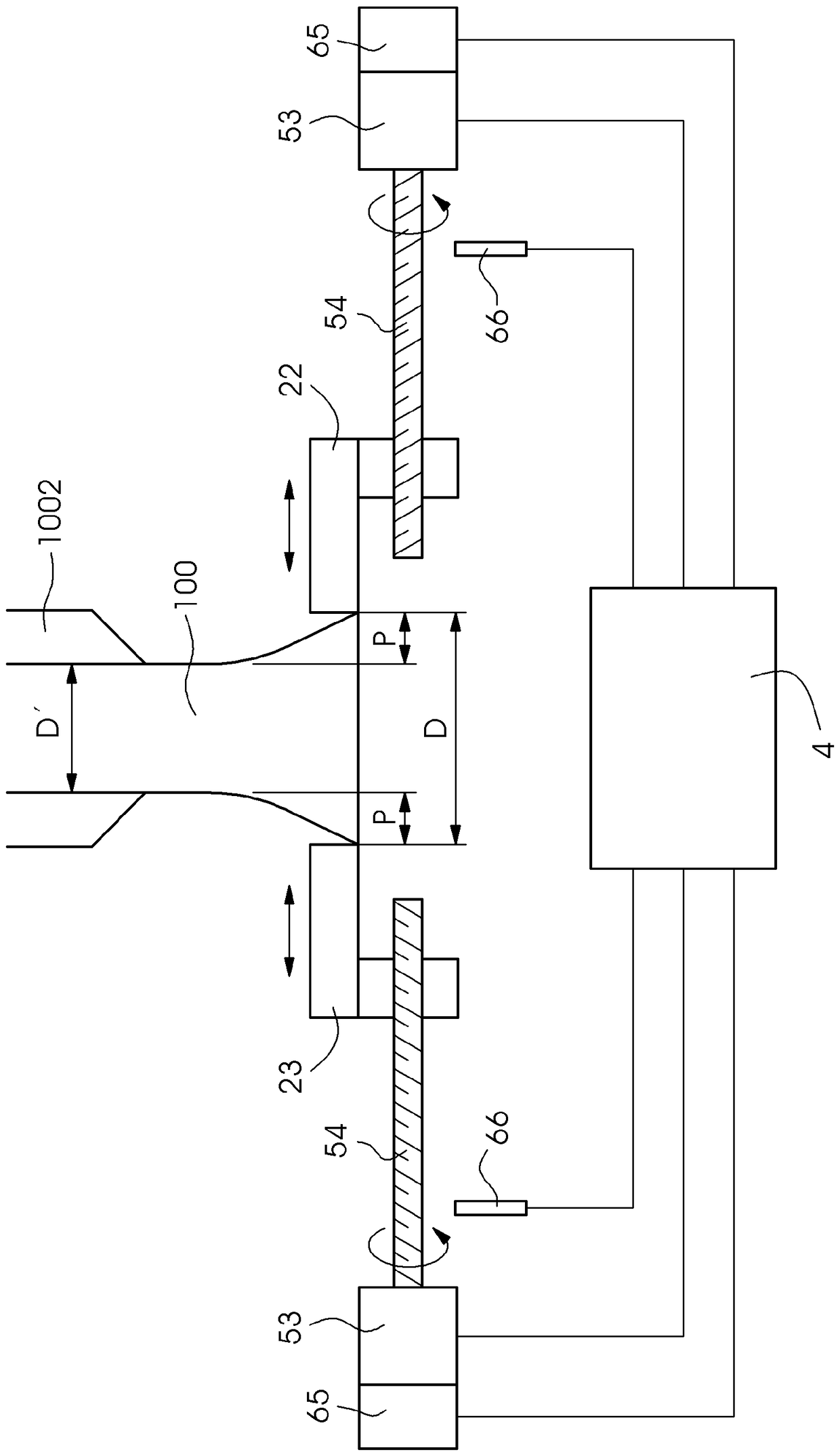

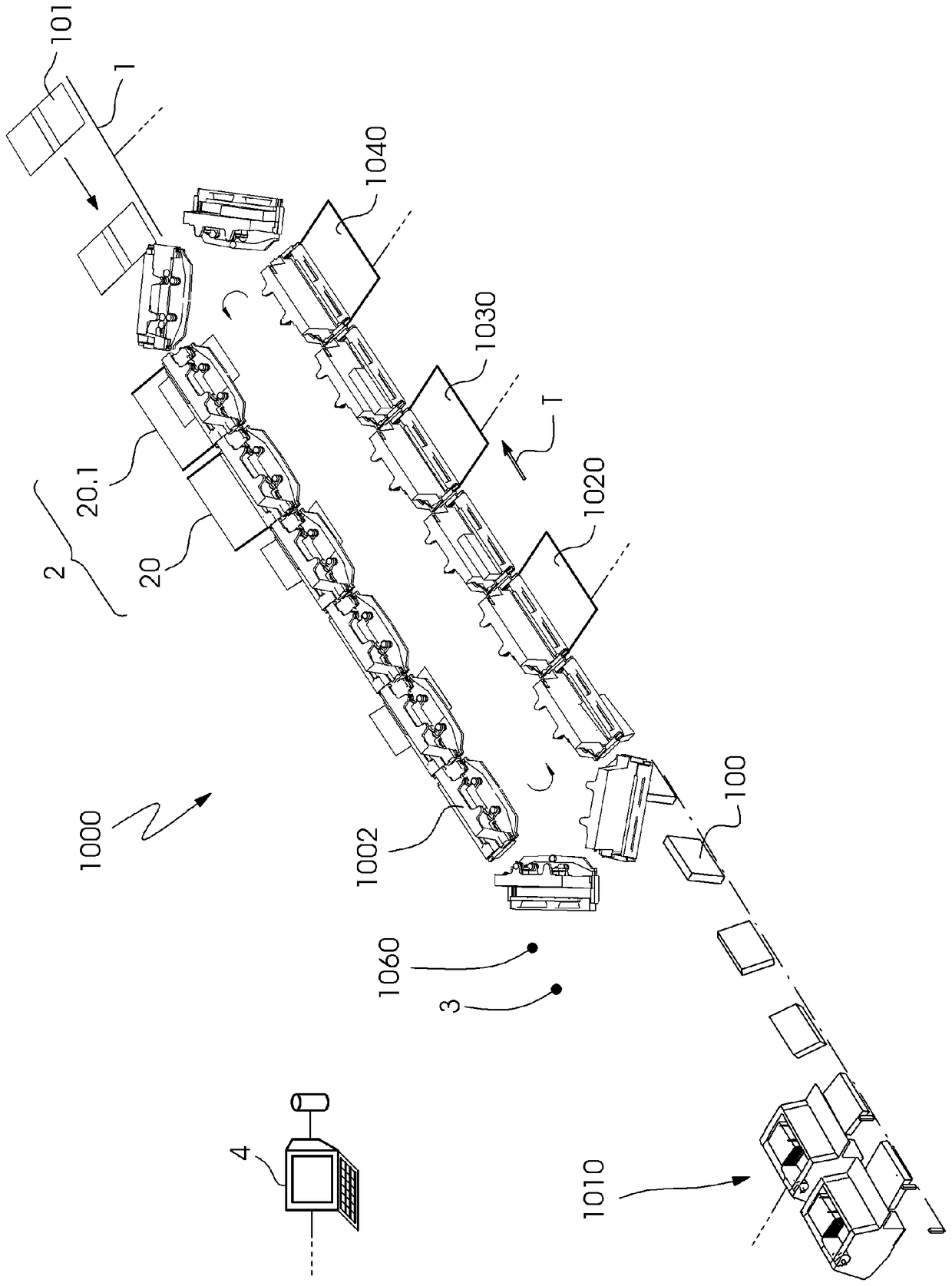

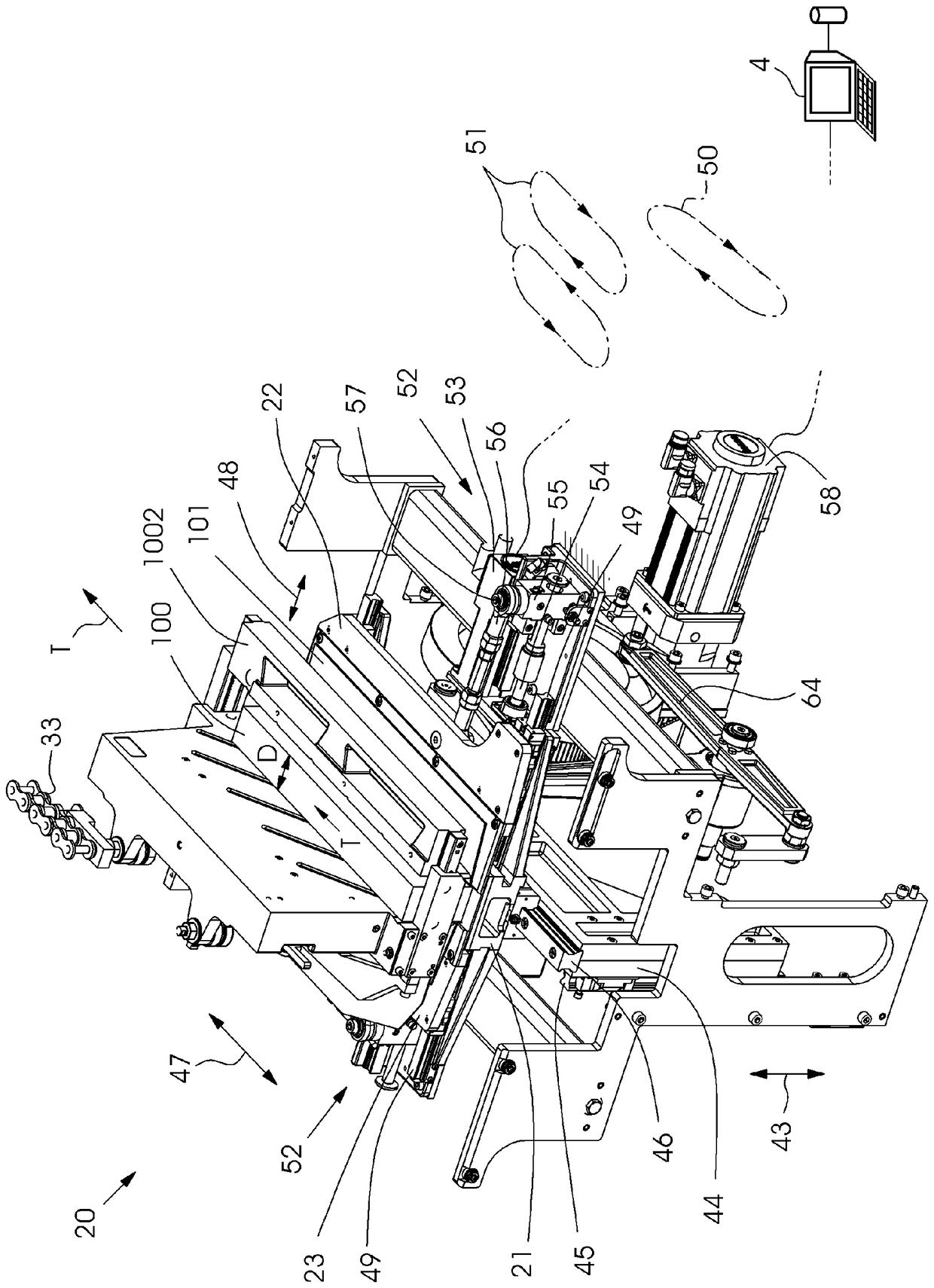

[0026] figure 1A section of a gluing binding machine 1000 is shown with a not-shown book block transport system 33 , which is formed by a driven, encircling chain with clips 1002 fastened thereto. The drive of the endless chain is formed, for example, by a servomotor (not shown). The book blocks 100 are supplied to the gluing binding machine 1000 by a collating machine 1010 along the transport direction T. Book blocks 100 are gripped by grippers 1002 and transported to a first processing station, spine processing station 1020 . The spine processing station 1020 can have a plurality of processing tools not shown. The book blocks 100 processed on their spines are transported further to the size application station 1030 and provided with glue. In the book back station (Fälzelstation) 1040 described below, book back protection strips can optionally be accommodated. In the device for abutting and fixing the covers 20.1 of the cover abutment and pressing station 2, the covers 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com