Inclined roller type heating furnace discharge device

A technology of discharging device and heating furnace, which is applied in the field of discharging device of heating furnace, and the discharging device of forged or annealed workpieces is arranged obliquely, which can solve the influence of the failure of the discharging device, the ingot slipping off the platform, and the weight of the ingot, etc. problem, to achieve the effect of extended life, novel design and good material guiding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

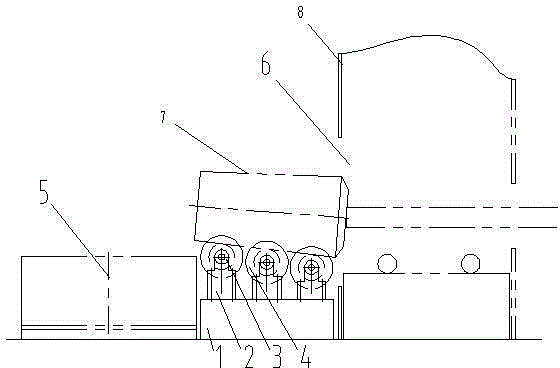

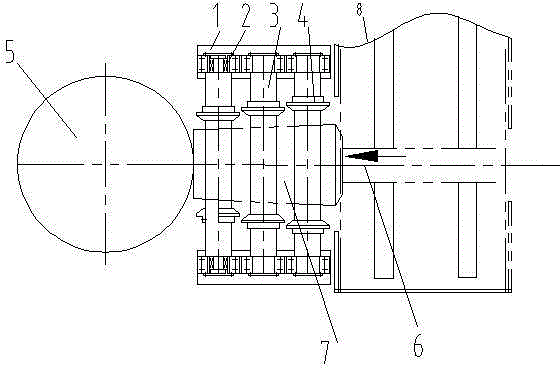

[0013] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0014] figure 1 As shown, the present invention is installed between the heating furnace discharge port 6 and the rotary platform 5, including a base 1, several conveying rollers 3, guardrails 4, lifting brackets 2, and several conveying rollers 3 are mounted on the base of the present invention , the front and rear conveying rollers 3 rise successively, the highest near the rotary platform 5, two guardrails 4 are respectively adorned on each conveying roller 3 (as shown), and the lifting bracket 2 and bearings are loaded onto the conveying roller 3 two ends.

[0015] The invention has the advantages of reasonable structure, novel design and good material guiding effect. The cast ingot falls smoothly on the rotary platform through the conveying rollers, prolonging its service life. Some workpieces that need to be slowly cooled on the conveyor roller to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com